Multi-link crank linkage and method for operating the same

A crank linkage mechanism and multi-link technology, applied in the direction of machines/engines, mechanical equipment, combustion engines, etc., can solve problems affecting the smooth operation of internal combustion engines, reduce knocking tendency, reduce ventilation loss, and improve Effect of Combustion Gas Pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

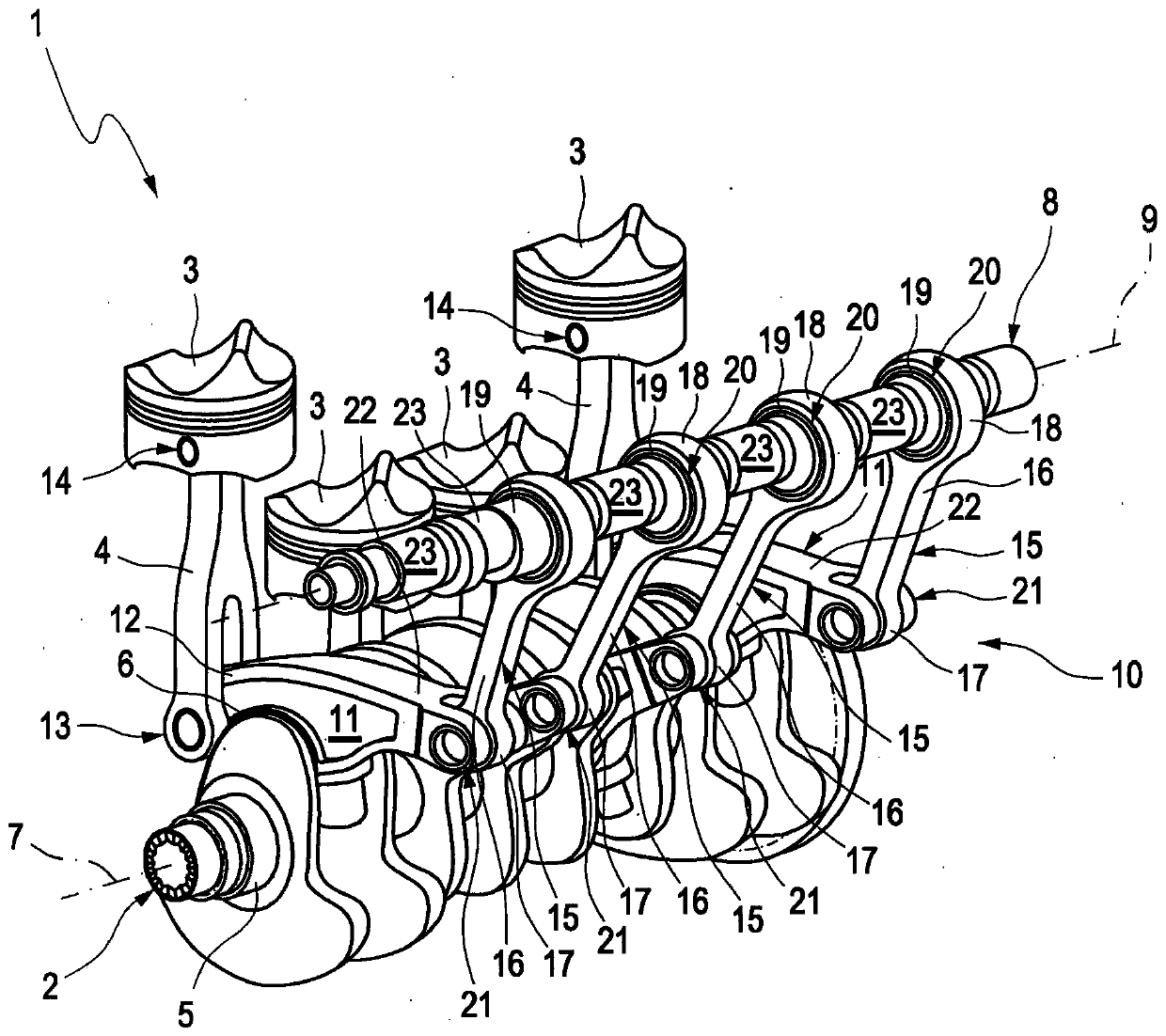

[0028] figure 1 A perspective view of a region of an internal combustion engine 1 is shown, which is present, for example, as a serial internal combustion engine, in particular a four-stroke four-cylinder serial internal combustion engine. Internal combustion engine 1 has a crankshaft 2 and a plurality of pistons 3 (here: four pistons 3 ), wherein each piston is movably mounted in one of the plurality of cylinders of internal combustion engine 1 . Each of the pistons 3 is connected to the crankshaft 2 via a piston connecting rod 4 . The crankshaft 2 is rotatably mounted in bearings, also not shown, of a cylinder crankcase (not shown here) of the internal combustion engine 1 and has, for example, a plurality of central journals 5 for bearing and a plurality of pin journals 6 (of which only one can be seen in each case in the figures), their longitudinal center axes are offset in different angular orientations parallel to the axis of rotation 7 of the crankshaft 2 .

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com