An intelligent high-efficiency steam oven

A steam oven, high-efficiency technology, used in steam cooking utensils, cooking utensils, household appliances, etc., can solve the problems of high noise, complicated installation, small size, etc., and achieve the effect of no pressure, low electric heating power, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

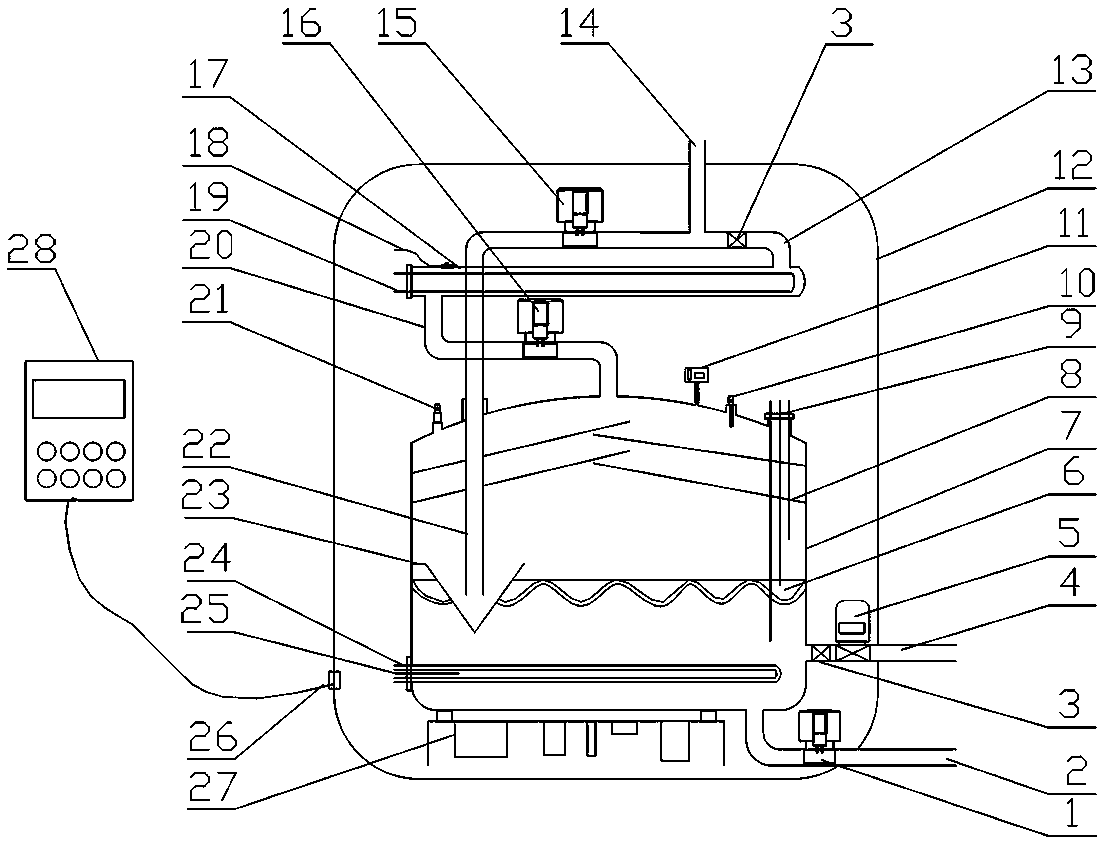

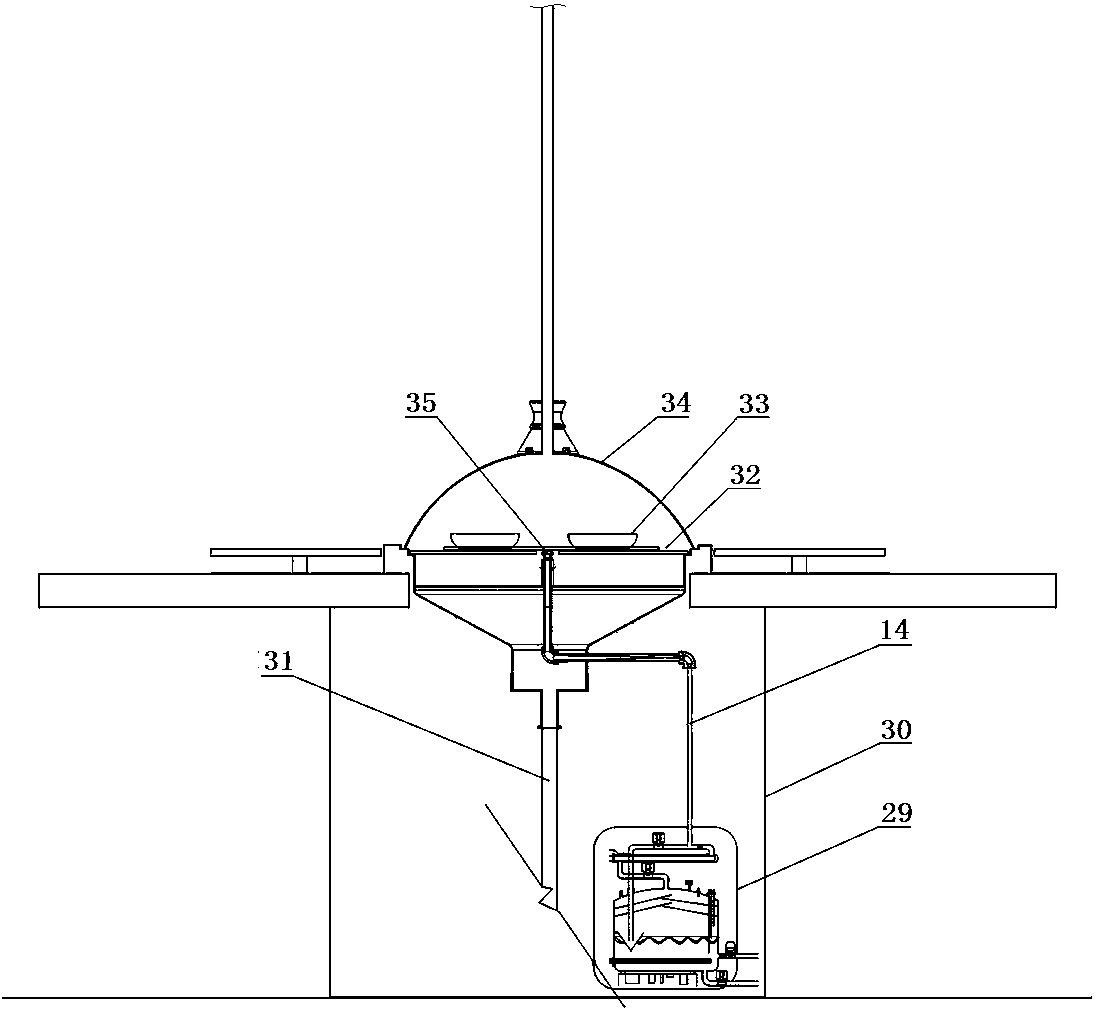

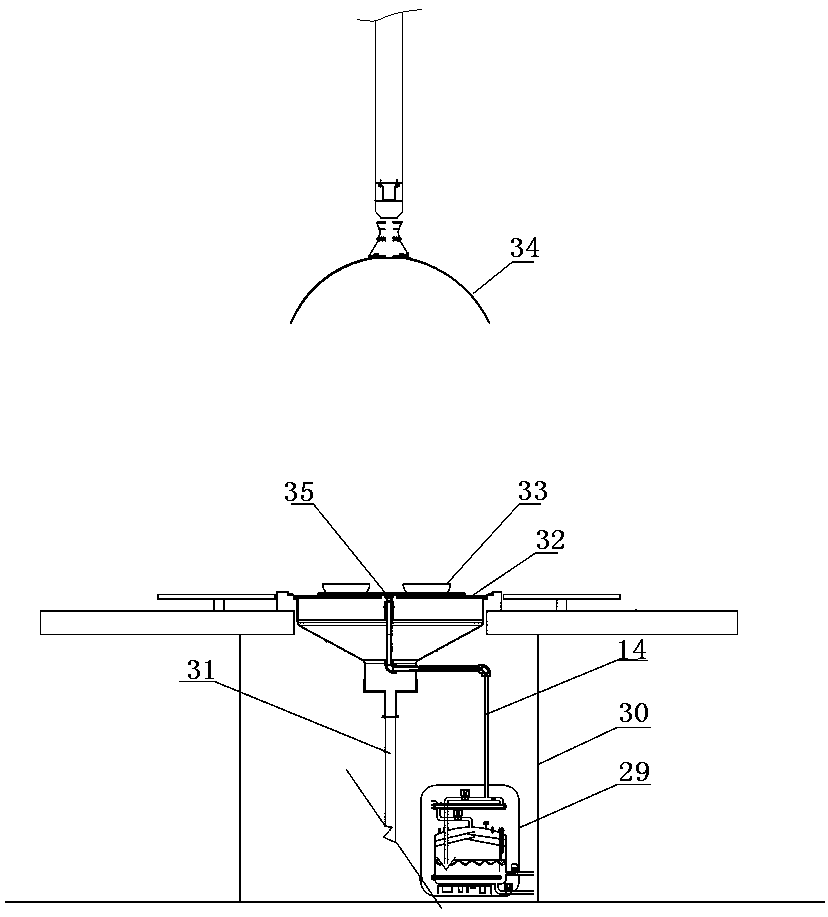

[0023] Example: such as figure 1 As shown, this embodiment specifically relates to an intelligent high-efficiency steam oven, which is applied to a dining table equipped with a steamer. The steam oven is mainly composed of a furnace 7, a steam secondary heating output unit, and a boiling water output unit.

[0024] The furnace 7 is a cavity structure with an upper dome and a lower cylinder. The bottom of the furnace 7 is respectively connected with a water inlet pipeline 4 for water supply and a drainage pipeline 2 for drainage. In the water inlet pipeline 4 A water inlet solenoid valve 5 for controlling the on-off of the pipeline and a one-way valve 3 for preventing the backflow of the inlet water are provided, and a drain solenoid valve 1 for controlling the on-off of the pipeline is also installed in the drain pipeline 2; in addition, in the furnace 7, the inner bottom is also provided with an electric heating device 24, which is used to heat the water in the furnace 7; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com