Plate flattening device

A leveling device and plate technology, which is applied in the field of plate leveling devices, can solve the problem of being unable to level short sheet-like plates, etc., and achieve the effect of reducing labor intensity and improving leveling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

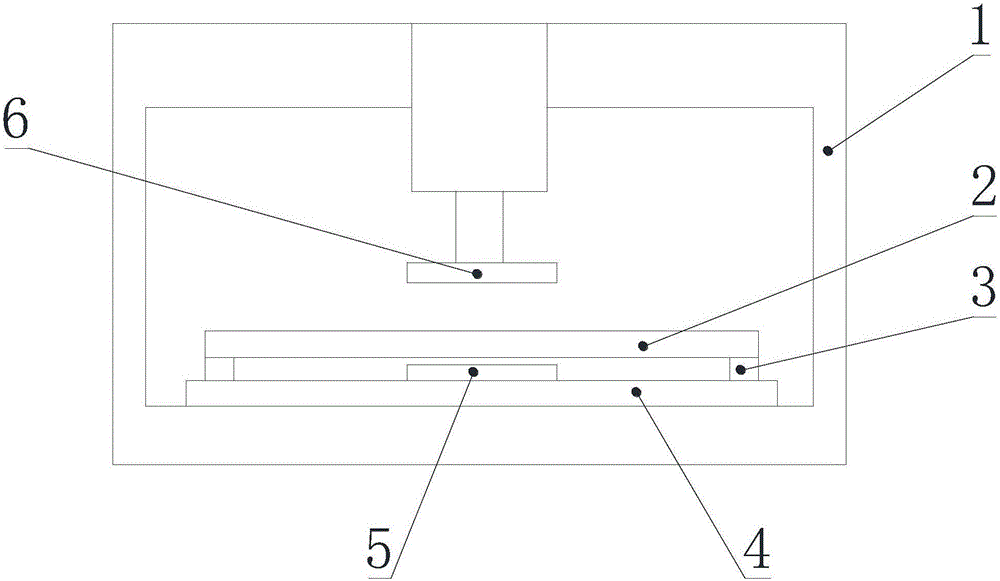

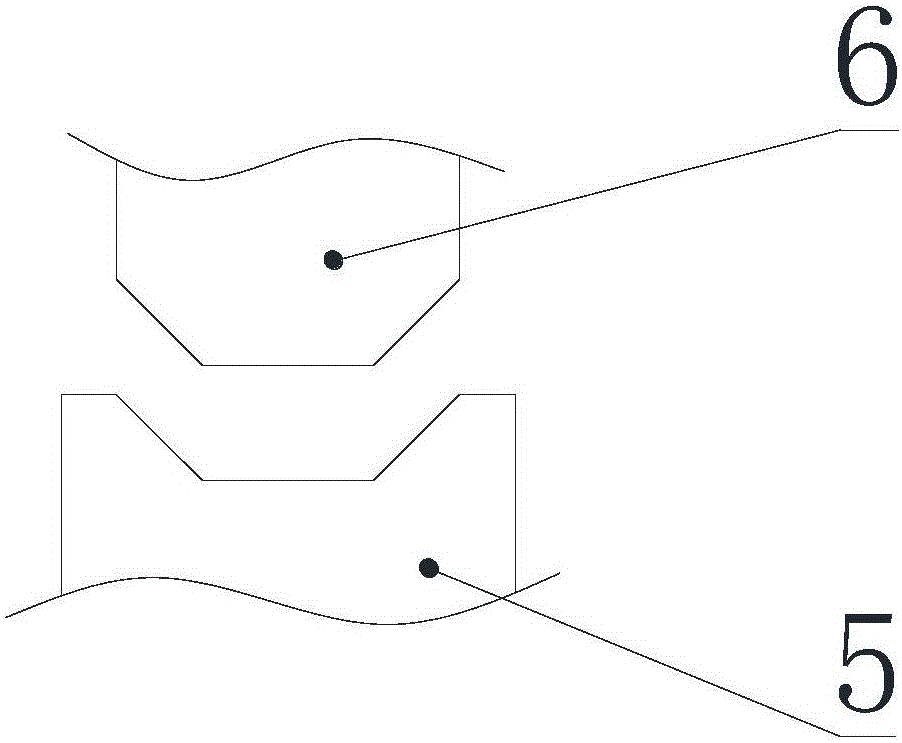

[0030] Such as figure 1 As shown, a plate leveling device includes a frame 1, an upper pressing head 6, a lower pressing head 5 and a plate fixing device, the upper pressing head 6 and the lower pressing head 5 are fixed on the frame 1, specifically, Described frame 1 is provided with workbench, and described workbench is provided with inverted U-shaped fixed beam, and lower pressure head 5 is fixed on the workbench, and upper pressure head 6 is fixed on the inverted U-shaped fixed beam, and upper pressure head 6 Driven by a driving device, the driving device can be an air cylinder, a hydraulic cylinder or a motor-driven guide rail mechanism, and its purpose is to realize the up and down movement of the upper pressing head 6 and realize the leveling of the plate. The upper pressing head 6 is arranged directly above the lower pressing head 5, and the middle of the lower pressing head 5 is recessed downward. The downward sag of the lower pressing head 5 can enable the overpress...

Embodiment 2

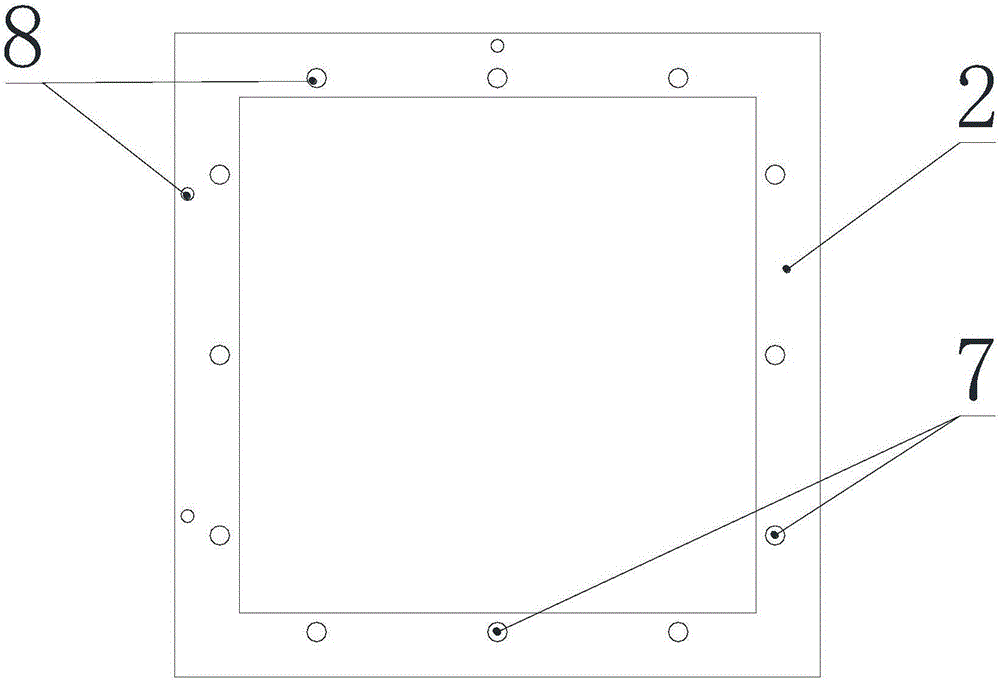

[0037] On the basis of Embodiment 1, the locking device can be an electromagnet 7 , and a plurality of electromagnets 7 are evenly distributed on each side of the fixed table 2 . When leveling the plates that can be absorbed by magnets, the electromagnet 7 can be used to clamp them, which is fast and convenient. And a distance sensor is provided under the fixed platform 2 . Multiple distance sensors are provided, and the distance sensors can detect the height of each position of the plate, thereby judging the flatness of the plate, and moving the plate that needs to be leveled to between the upper pressing head 6 and the lower pressing head 5 . The first guide rail 4 and the second guide rail 3 are respectively driven by the first motor and the second motor to realize the X and Y direction movements of the fixed table 2, and a controller is set so that several distance sensors are respectively connected to the input ends of the controller, The electromagnet 7, the first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com