Spinning bobbin reversing device

An inverted tube and flat plate technology, applied in the textile field, can solve the problems of unfavorable production efficiency, heavy weight, time-consuming and laborious, etc., and achieve the effect of good promotion and utilization value and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

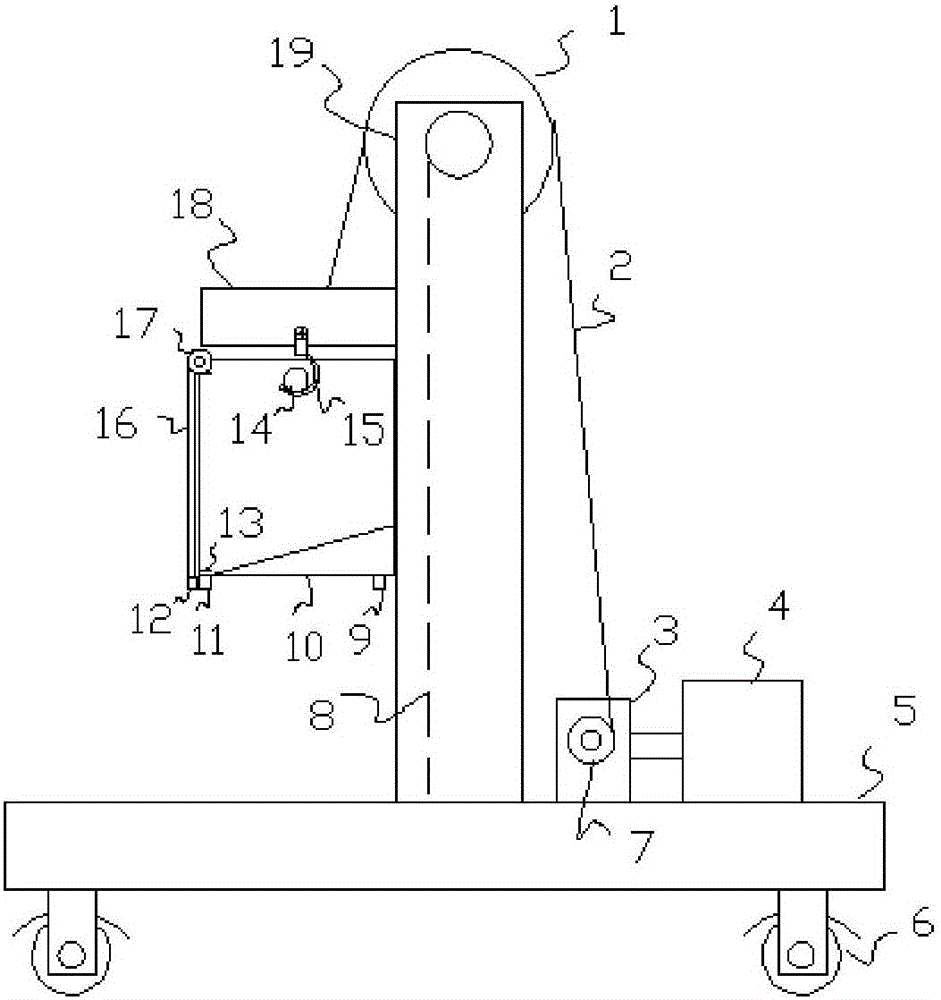

[0020] Such as figure 1 , figure 2 As shown, the structure of this kind of inverted tube device for weaving includes a flat plate 5, on which a vertical rod 19 is arranged, and a pulley 1 is hinged to the upper end of the vertical rod 19.

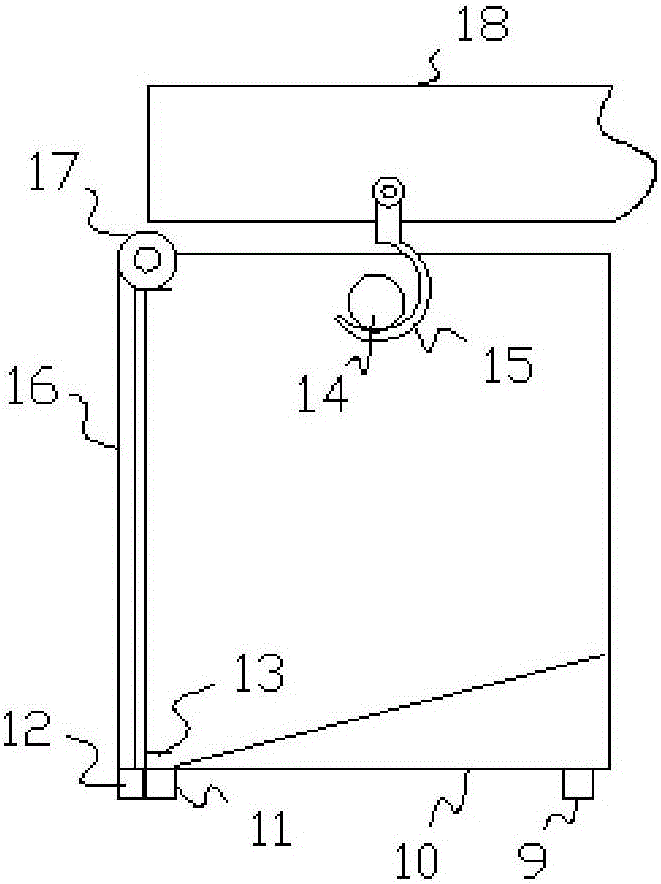

[0021] In the above embodiment, specifically, the left side of the vertical rod 19 is embedded with a slideway 8, and a slideway 8 protruding to the left is provided in the slideway 8, and the two sides of the slideboard 18 are hinged with hooks 15, and the hooks 15 Cooperate with the hanging ears 14 on the material storage box 10 below. When in use, the material storage box can temporarily store textile bobbins, and can freely slide up and down in the slideway through the slide plate, so as to prepare for the lifting of the material storage box at the back.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com