Multi-piece large-area single-sided or double-sided superconducting thin film substrate fixture

A technology of superconducting thin film and substrate clip, applied in the manufacture/processing of superconductor devices, metal material coating process, coating, etc., can solve the problems of inconvenient installation process, affecting production efficiency, low production efficiency, etc., to achieve Save installation time, improve production efficiency, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

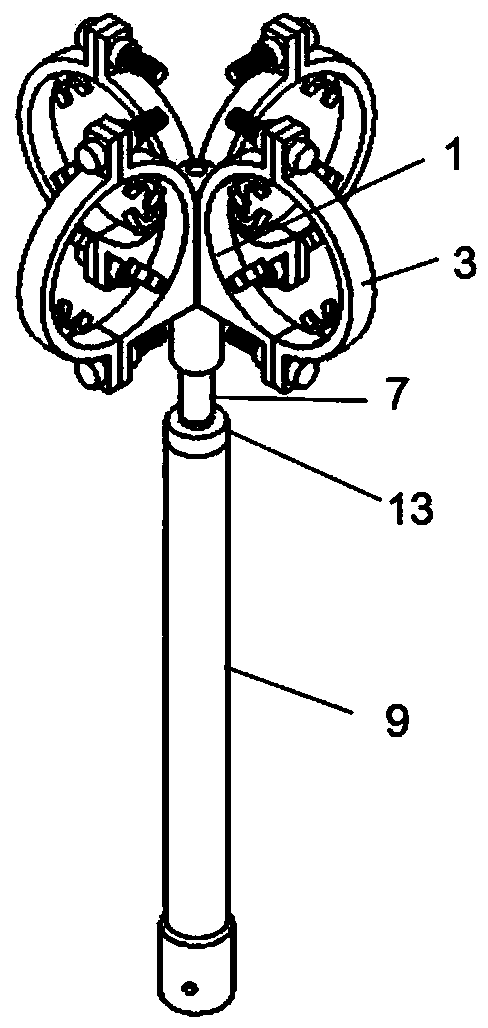

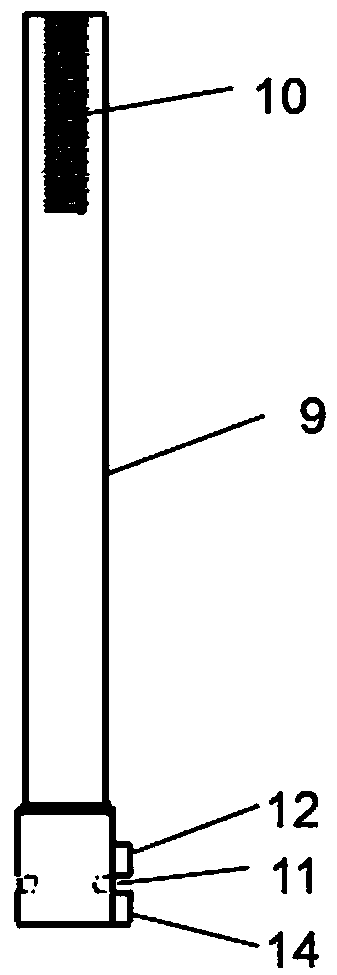

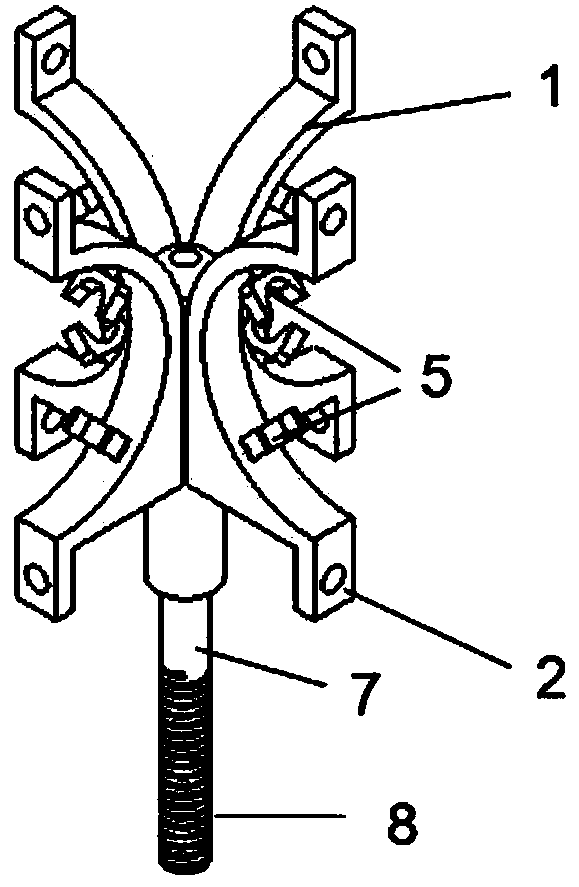

[0027] Put a plurality of substrates coated with superconducting thin films into the fixture of the present invention sequentially according to the above method, and in a heat treatment furnace at a temperature of 600-900 ° C, the fixture is driven by a motor to rotate continuously at a constant speed around its axis for 60 hours, and the prepared The multiple superconducting thin film substrates are intact and have good performance, and the performance of the multiple superconducting thin film substrates is consistent.

Embodiment 2

[0029] A plurality of substrates coated with a superconducting thin film are sequentially loaded into the fixture of the present invention according to the above method, and in a heat treatment furnace at a temperature of 600-900°C, the fixture is driven by a motor to reciprocate for 60 hours, and the multi-chip superconducting film is prepared. The conductive thin film substrates are all intact and have good performance, and at the same time, the performances of multiple superconductive thin film substrates are consistent.

[0030] Compared with the prior art, the multi-piece large-area single-sided or double-sided superconducting thin film substrate clamp of the present invention has the following beneficial effects:

[0031] 1. In the present invention, the substrate holder includes a plurality of semicircular fixed fixtures and a plurality of semicircular movable fixtures, which realizes firing multiple superconducting thin film substrates at one time, improves the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com