Automatic thread winding and cutting integrated winder

A technology of automatic thread winding and bobbin winder, which is applied to bobbin winding in sewing machines, sewing equipment, textiles and paper making, etc. It can solve the problems of high cost, troublesome and time-consuming operation, complicated installation, etc., and achieves convenient operation and high thread volume. Adjust the effect of humanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

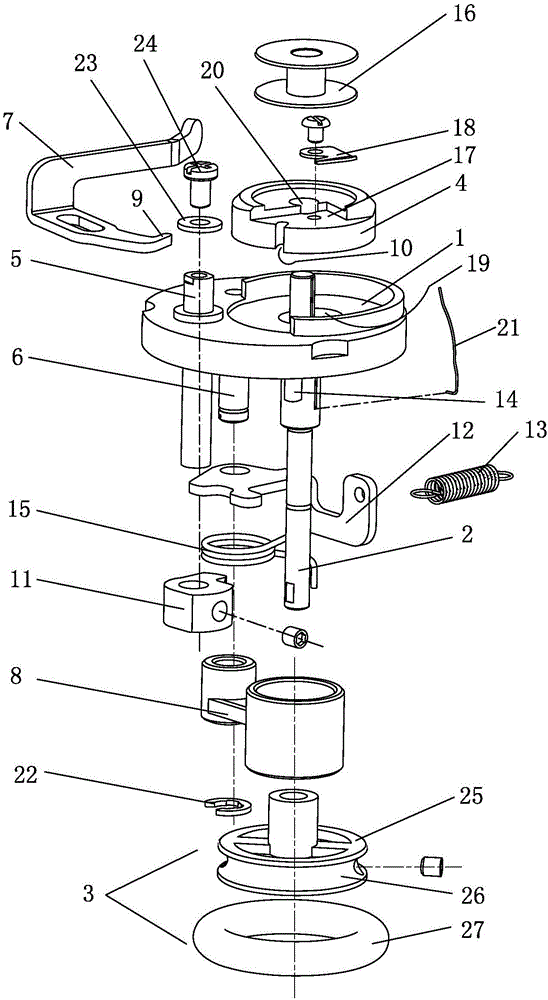

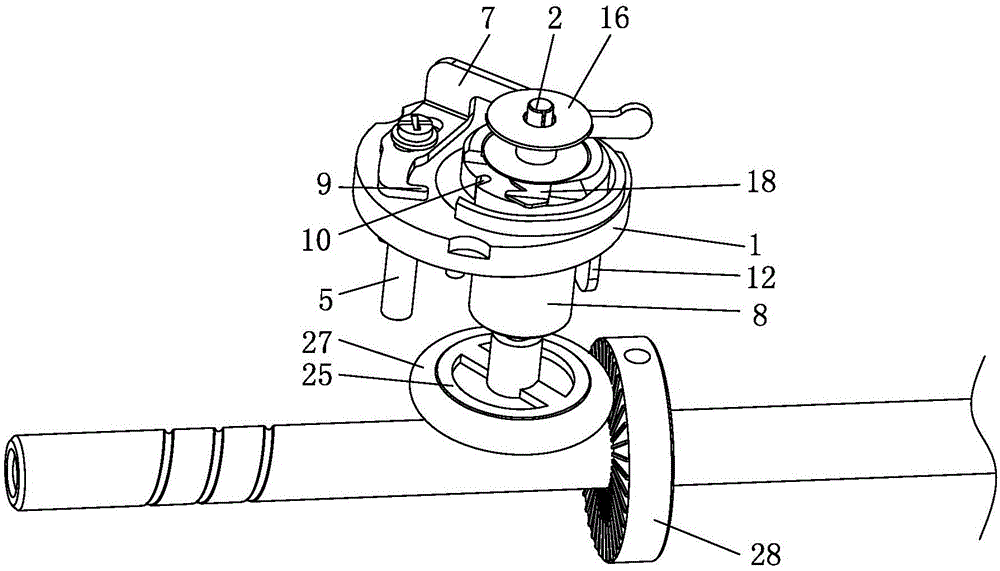

[0022] Embodiment one: see figure 1 —3:

[0023] An automatic winding and secant integrated wire winder, comprising a main body of the wire winder 1, on which a main shaft 2 of the wire winder capable of translating relative to the main body of the wire winder 1 is arranged, and the winding The lower end of the winder main shaft 2 is fixedly provided with a winding wheel 3, and the winding liner 4 is connected to the upper end of the winding liner main shaft 2 and is located above the main seat 1 of the winding liner, and the winding liner 4 above the winding liner main shaft 2 For set bobbin 16. Winder main seat 1 is also provided with winding camshaft 5, pin 6, and winding camshaft 5 is provided with crimping control board 7, and one end of winding device connecting rod 8 is sleeved on the winding device main shaft 2, and the other end is set on the pin 6, and the 7-position pressing control board is arranged above the main seat 1 of the winding device, and the winding cam...

Embodiment 2

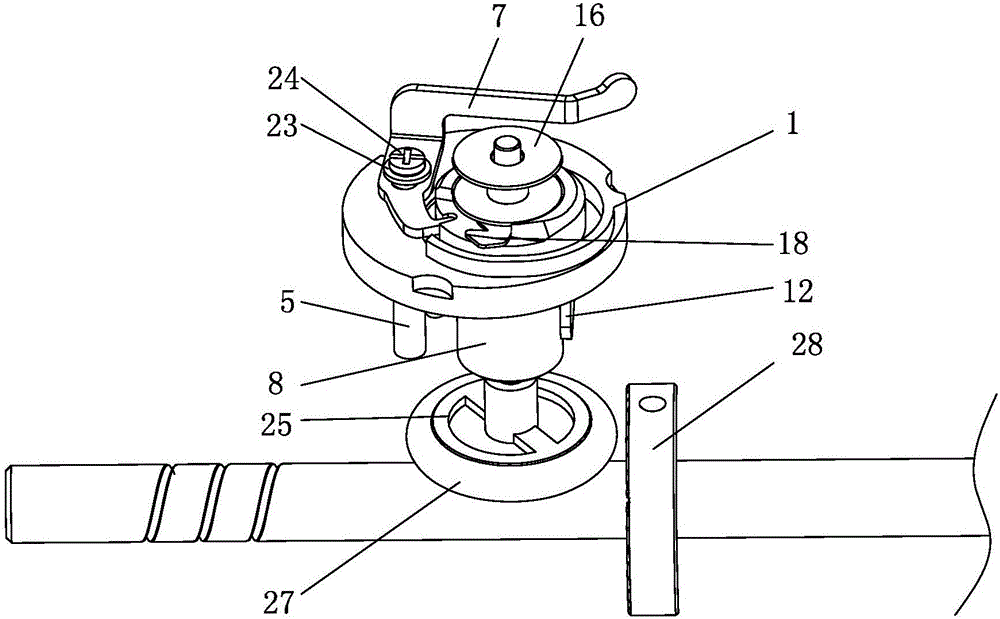

[0036] Embodiment two: see Figure 4 , 5 :

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in the structure of the braking device:

[0038] Described braking device comprises the brake cam 29 that is arranged on the lower end of the main shaft 2 of the winder or is arranged on the winding wheel with a set track, the limit card slot 30 is arranged on the brake cam 29, and the winding camshaft 5 can Connect with the limit card slot 30 to realize braking.

[0039] The working principle of this embodiment:

[0040] A braking cam 29 with a specific track is added on the lower end of the winding device main shaft 2 or on the winding wheel, and braking is performed by the relative position change of the braking cam 29 and the winding camshaft 5 . Such as Figure 4 Shown is a schematic view of the wire winder when it is working, the wire pressing control plate 7 is pulled, the O-ring 27 is in contact with the wire windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com