Tramcar turnout point rail heel structure

A technology for trams and pointed rails, which is applied to the superstructure of the track, the track, the road, etc., can solve the problems of time-consuming and laborious disassembly, and the safety factor needs to be verified, so as to achieve the effects of maturity and reliability, convenient manufacturing and reliable safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

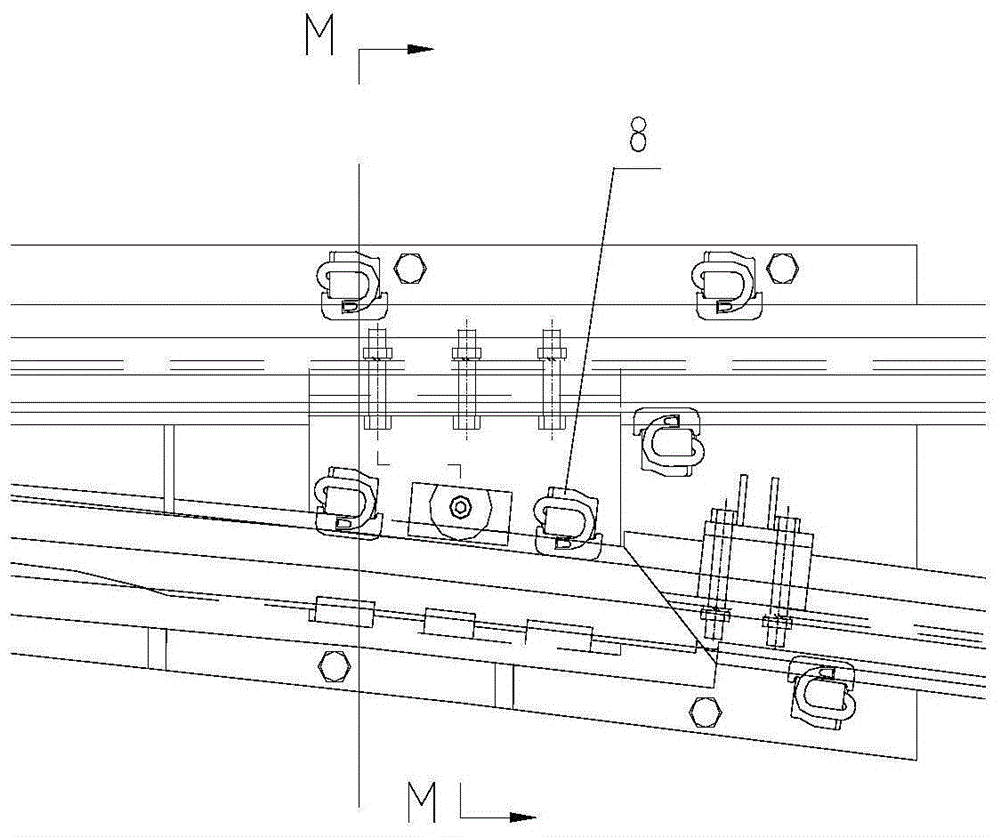

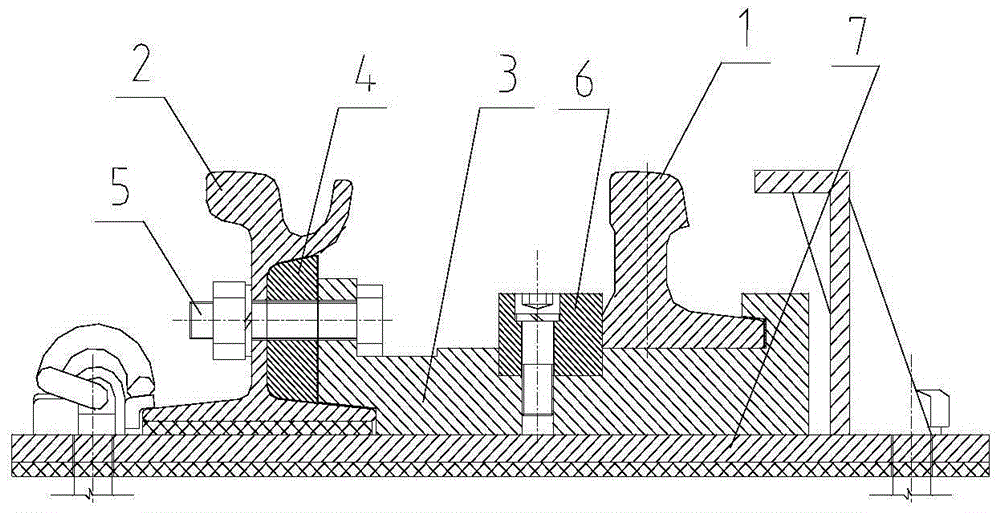

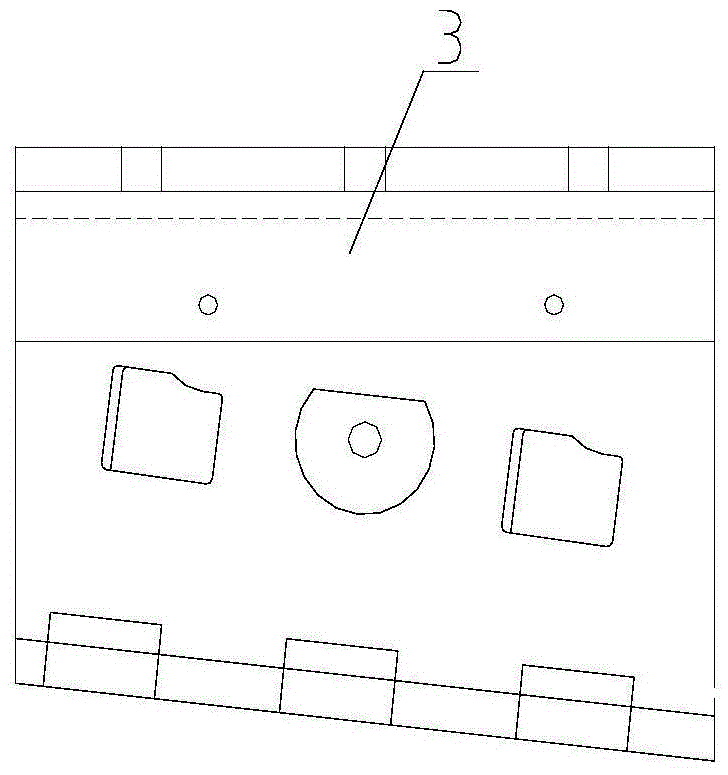

[0021] Embodiment 1: refer to attached Figure 1-7 . A tramway turnout point rail heel structure, the platform 3 is located on the backing plate 7, and the bottom side of the platform 3 is provided with a downward pressure tongue 33 for clamping the basic rail 2, and the downward pressure tongue 33 is clamped on the surface The slope matches the slope of the bottom of the basic rail 2. There is a boss 31 on the upper side of the platform 33. The boss 31 has a bolt through hole 32 in the transverse direction. The middle part of the platform 3 has a positioning pin slot 35 and the positioning pin slot The bottom of 35 is provided with a screw hole 36 for bolt screwing, the upper part of the other side of the platform 3 has a boss 38, and the inner side of the boss 38 is provided with a tongue and groove for fastening the tip rail 1; the bottom surface of the basic rail 2 is inserted into the bottom of the platform 3 Inside the tongue opening 33 on one side, the bolt 5 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com