Axial parallel clutch driving device based on radial-moving clutch pin

A technology of clutch transmission and clutch pin, which is applied in the field of mechanical transmission and can solve the problems of large separation and implicated torque of the expansion and tightening structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

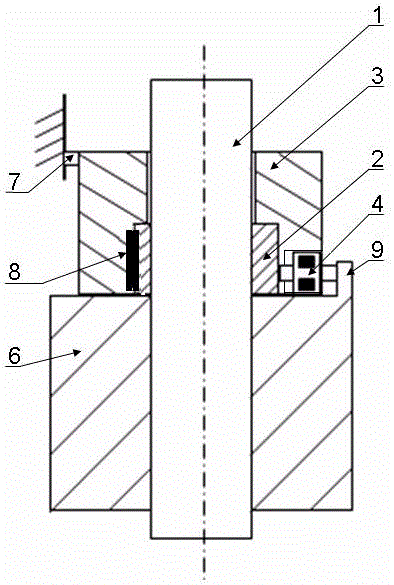

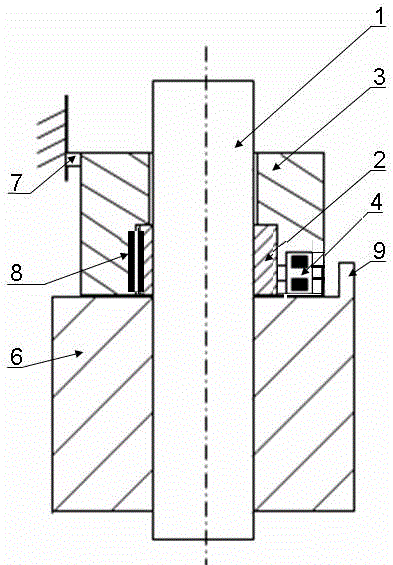

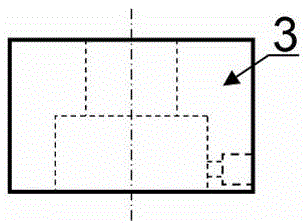

[0017] Combine below figure 1 , 2 , 3, 4, 5 and 6 are further detailed descriptions of the embodiments of the patent of the present invention.

[0018] Embodiment of the present invention's axially parallel clutch transmission based on radially moving clutch pins: this clutch transmission consists of an active rotating part [1], a radially driving rotating part [2], a sleeve with a radial pin hole [3], clutch pin [4], magnet [5], driven rotating part [6] with a stop, sleeve rotating damping part [7], respectively located in the radial direction of the driving rotating part [2] and the belt diameter It is composed of the rotation stop contact pair [8] on the sleeve [3] of the pin hole, wherein, such as Image 6 As shown, when the driven rotating part [6] is processed, the convex edge in the circumferential direction is reserved as the stop [9], the clutch pin [4] is embedded with a magnet [5], and the radially driving rotating part [2] adopts Figure 5 The one on the left is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com