Automobile electromechanical brake with gap adjusting function

A technology for mechanical brakes and clearance adjustment, applied in slack adjusters, brake types, axial brakes, etc., can solve the problem of failure to ensure the consistency of vehicle braking response, lack of automatic adjustment of brake clearance, and inability to meet loading requirements. requirements and other issues to achieve the effect of ensuring braking performance, small installation space and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

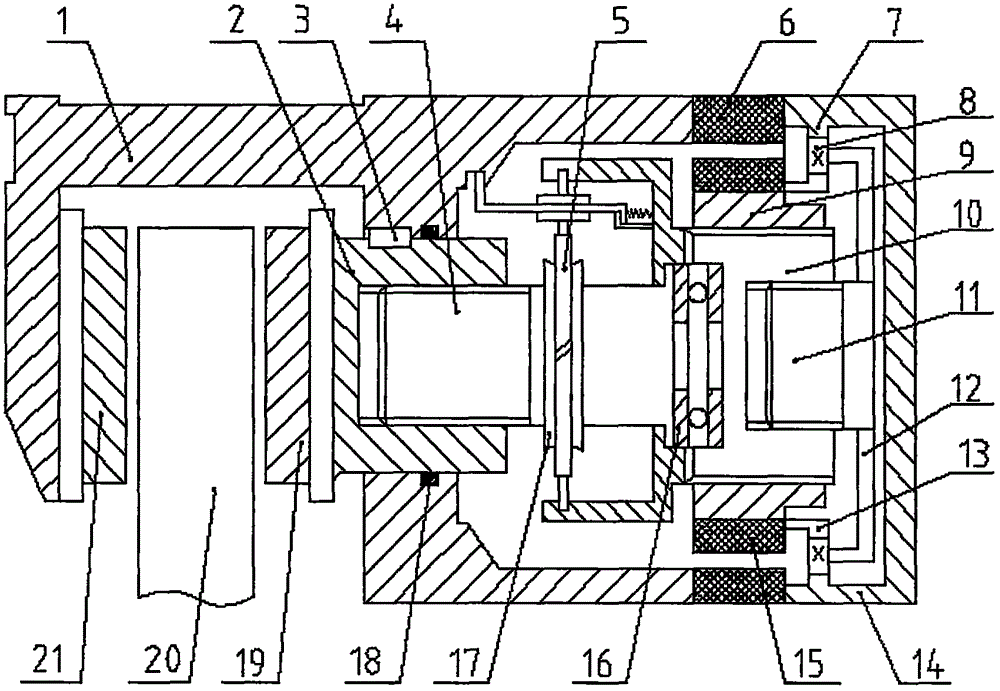

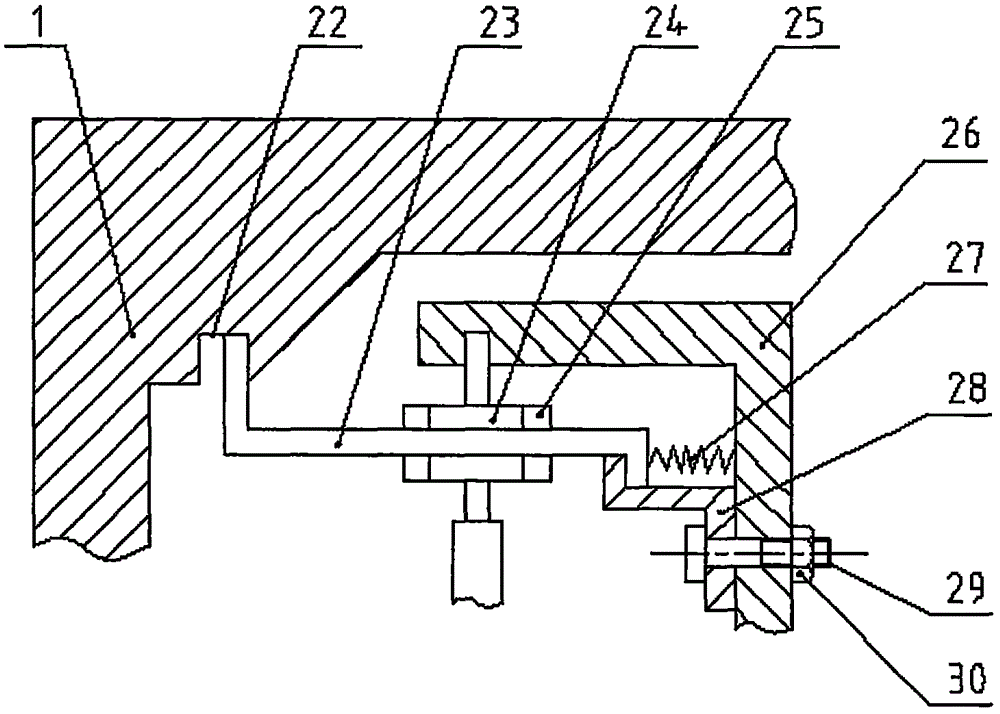

[0032] Such as figure 1 As shown, the automotive electromechanical brake with gap adjustment function of the present invention is characterized in that it includes a brake disc 20, friction plates are arranged on both sides of the brake disc 20, the front friction plate 21 is fixedly connected with the floating caliper body 1, and the rear The friction plate 19 is fixedly connected with the piston 2; the piston 2 is connected with the floating caliper body 1 through a rectangular sealing ring 18, and a flat key 3 is installed on the piston 2 to make the piston 2 move axially along the floating caliper body 1. The planetary gear reduction mechanism includes a center wheel 13, a planetary wheel 8, an external gear 7, and a planet carrier 12; the brake motor includes a motor stator 6 and a motor rotor 15; the motor stator 6 is fixedly installed on the floating pliers 1, and the motor rotor 15 is nested Outside the spline support frame 9, radial rotation can be realized, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com