A method for testing the strength of guide plate solder joints using a pressure testing machine

A pressure test and strength detection technology, which is applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc. Simple operation, convenient tracking and monitoring, and quick judgment of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

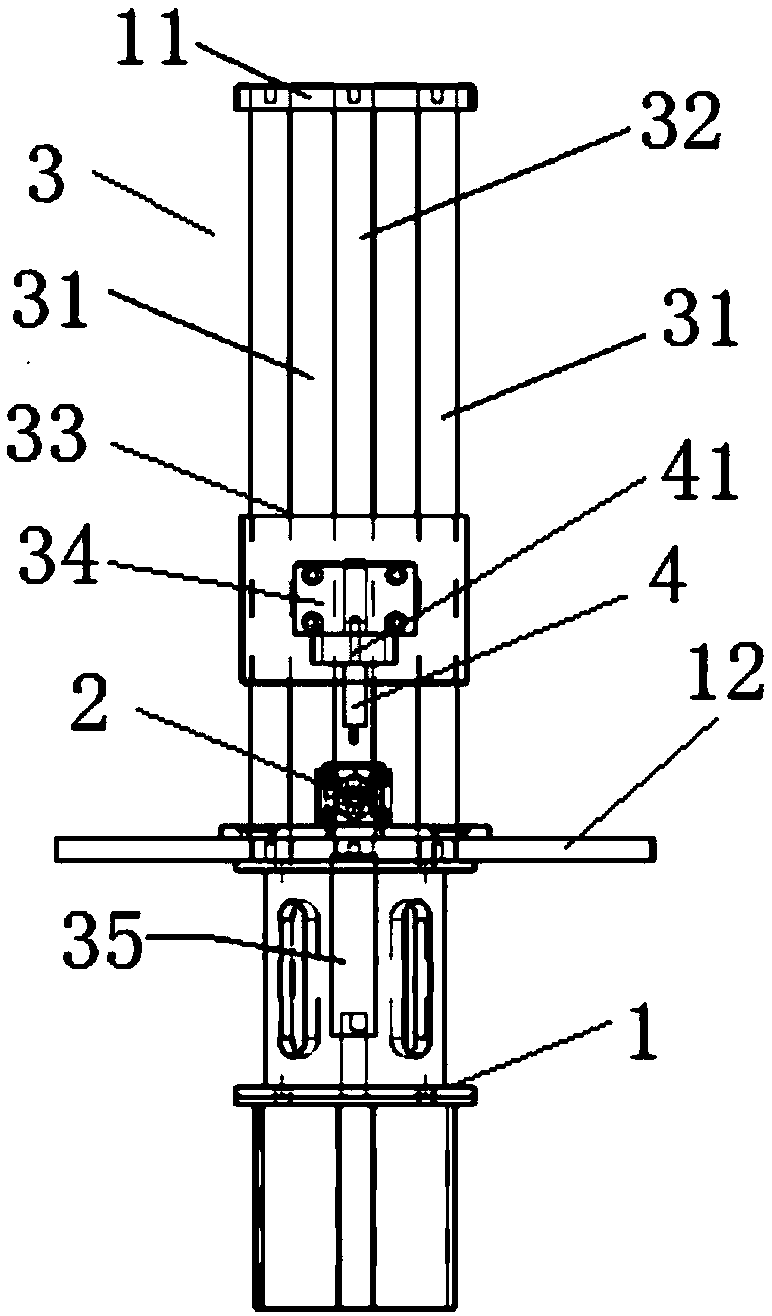

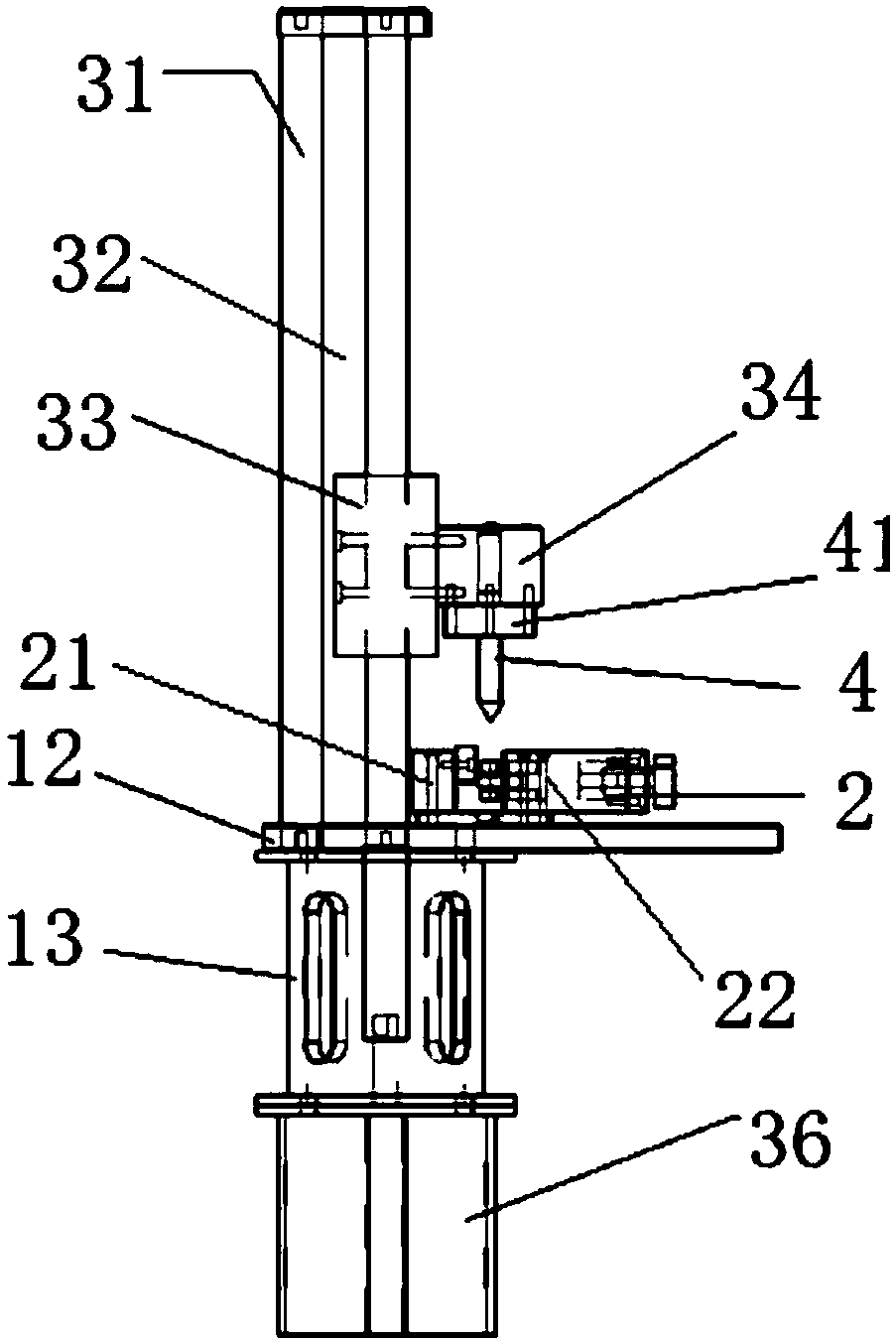

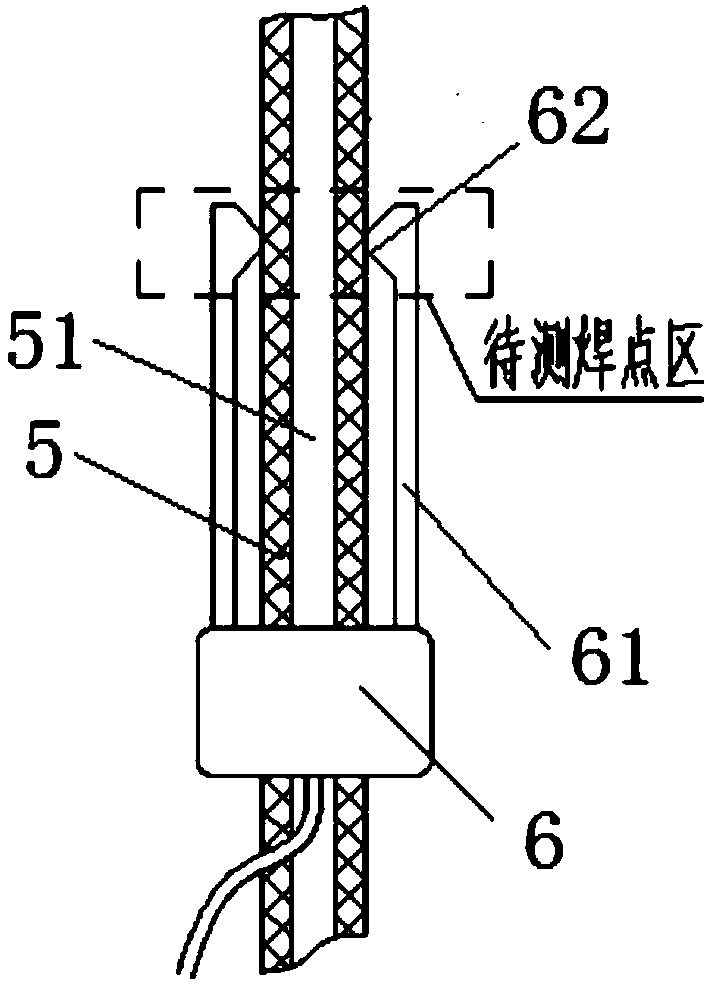

[0020] The following combination Figure 1 to Figure 4 A spot welding guide wedge wedge pressure testing machine and a method for detecting spot welding spot strength of a spot welding guide wedge using the spot welding guide wedge pressure testing machine are described in detail.

[0021] Such as figure 1 and figure 2 As shown, this spot welding guide plate wedge pressure testing machine comprises frame 1, and the middle part of described frame 1 is provided with platform 12, and described platform 12 is provided with the guide plate fixture 2 that is used for clamping spot welding guide plate 5, and described guide plate A wedge-shaped pressing block 4 is provided directly above the fixture 2, and the wedge-shaped pressing block 4 is arranged on the lifting guide rail mechanism 3. The servo motor 36 drives the wedge-shaped pressing block 4 to lift along the lifting guide rail mechanism 3, and the wedge-shaped pressing block 4 is positioned between the servo motor 36 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com