A Method for Testing the Strength of Concrete Joint Surface by Acoustic Wave

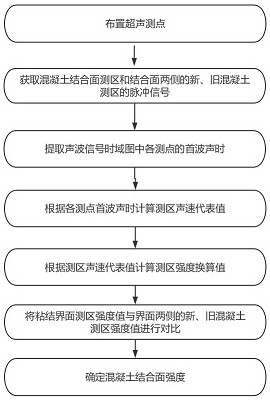

A technology for concrete bonding and sound wave detection, which is applied in the field of sound wave detection of the strength of the concrete joint surface, can solve the problems such as the inability to detect the strength of the concrete joint surface, and achieve the effects of intuitive and accurate judgment results, simple operation and wide detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0046] Example Experimental Model Test

[0047] (1) The strength grades and material mix ratios of the new and old concrete poured in this experiment are shown in Table 1:

[0048] Table 1

[0049] category power level water (kg) Cement (kg) Sand (kg) Stone(kg) new concrete C30 185 411 559 1245 old concrete C40 185 420 572 1273

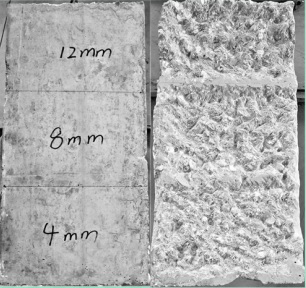

[0050] (2) The production process of the concrete joint surface model specimen is divided into three steps: making the old concrete specimen; processing the roughness of the bonding interface; pouring new concrete. The geometric dimensions of the old concrete specimen and the new concrete specimen are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com