Uncooled infrared detector device and manufacturing method thereof

A technology of uncooled infrared and production methods, which is applied in the field of infrared detection, can solve problems such as large working voltage, achieve easy excitation, and improve the effect of voltage temperature response coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

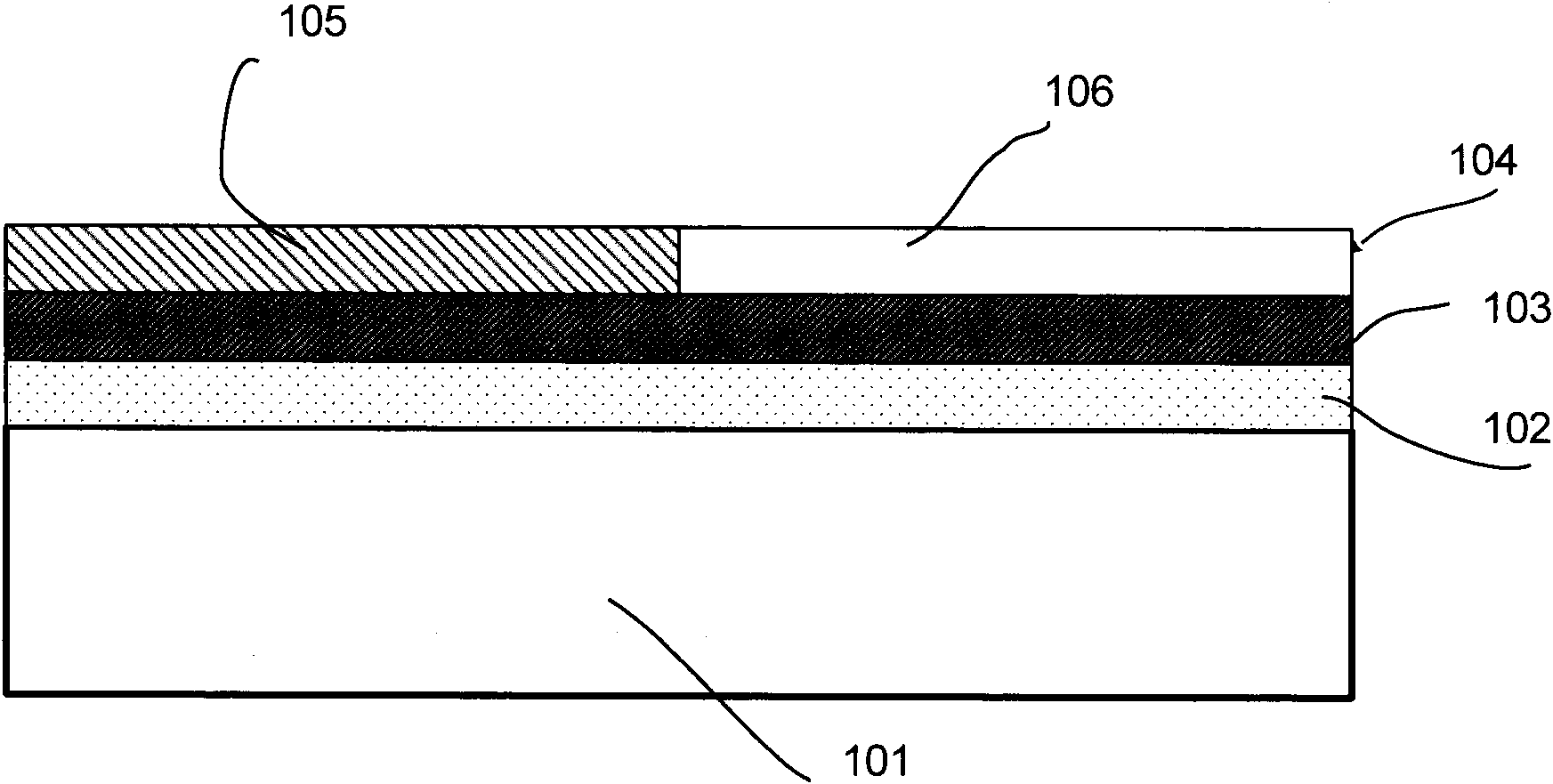

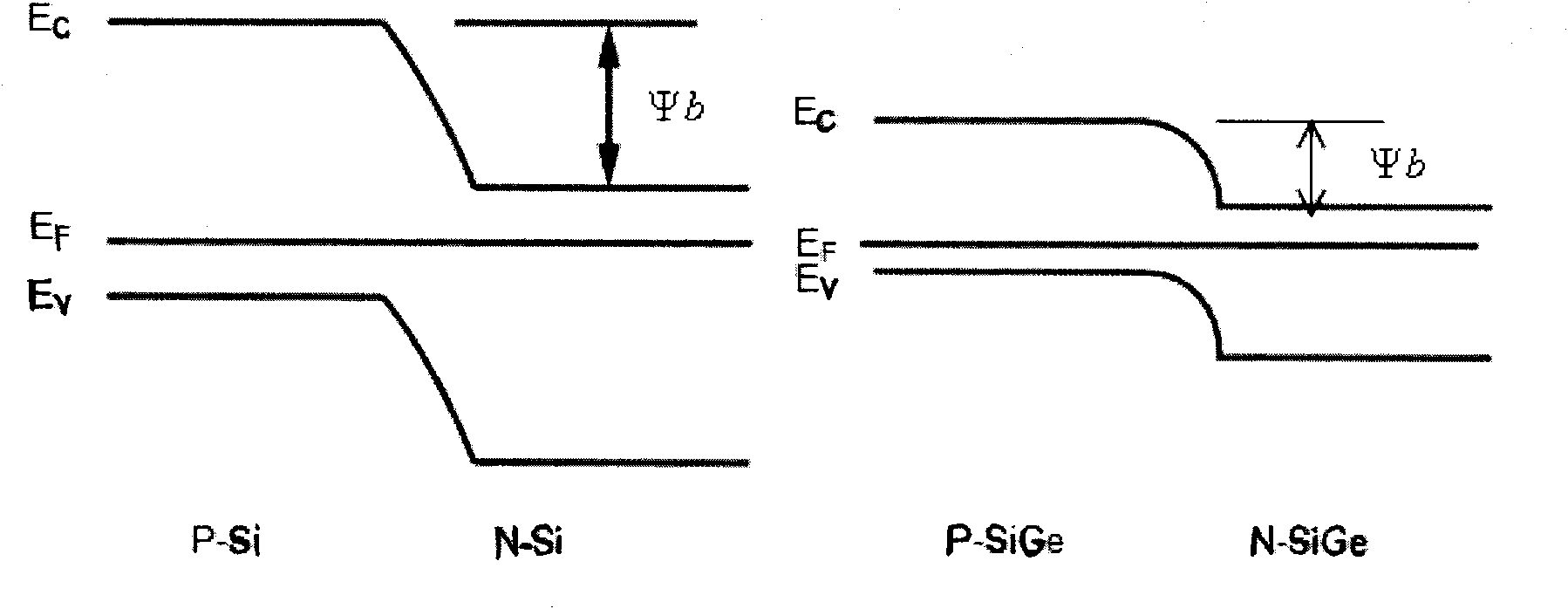

[0052] figure 1 It is a schematic structural diagram of the uncooled infrared detection device in this embodiment, figure 2 It is a diagram comparing the energy bands of the SiGe PN junction and the traditional single crystal silicon PN junction in this embodiment.

[0053] Such as figure 1 As shown, uncooled infrared detectors include:

[0054] SOI (Silicon On Insulator, silicon on insulator) substrate;

[0055] Si on the SOI substrate x Ge 1-x layer 104, and the SiGe layer 104 includes adjacent P-type regions 105 and N-type regions 106.

[0056] Wherein, the SOI substrate is composed of a bottom silicon layer 101, a buried oxide layer 102 and a top silicon layer 103, both of which are monocrystalline silicon materials. For an infrared detection device, the top silicon layer 103 and the buried oxide layer 102 should be as thin as possible, and the thickness range is, for example, 50nm-200nm. The SOI substrate is made by implanting oxygen ions on a single crystal silic...

Embodiment 2

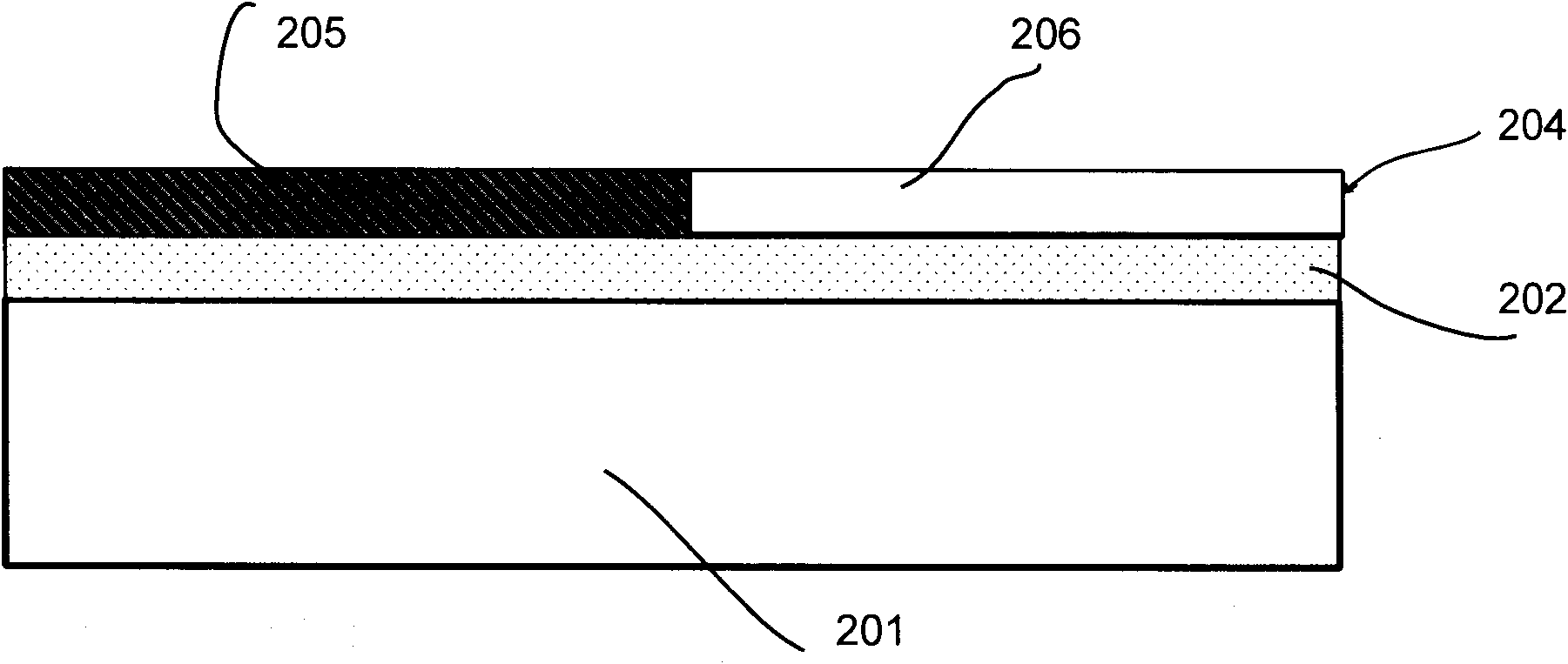

[0071] image 3 It is a schematic structural diagram of the uncooled infrared detection device in this embodiment. As shown in the figure, the uncooled infrared detector includes:

[0072] a single crystal silicon substrate 201, the single crystal silicon substrate 201 has a buried oxide layer 202;

[0073] Si on the buried oxide layer 202 x Ge 1-x layer 204, the Si x Ge 1-x Layer 204 includes adjacent P-type regions 205 and N-type regions 206 .

[0074] The difference from Example 1 is that the Si x Ge 1-x Layer 204 is on buried oxide layer 202 rather than on the top silicon layer.

[0075] The substrate of this embodiment does not have a top silicon layer, and the specific manufacturing method is: first epitaxially grow Si on the single crystal silicon substrate. x Ge 1-x layer, followed by oxygen ion implantation on the monocrystalline Si substrate and Si x Ge 1-x A buried oxide layer is formed at the interface of the layer, and then Si is formed by photolithogra...

Embodiment 3

[0079] Figure 4 It is a schematic structural diagram of the uncooled infrared detection device in this embodiment, Figure 5 Si in this example x Ge 1-x Energy band comparison diagram of / Si heterojunction and traditional single crystal silicon PN junction.

[0080] Such as Figure 4 As shown, the uncooled infrared detection device includes:

[0081] SOI substrate, the SOI substrate has an N-type top silicon layer 303;

[0082] The P-type Si on the N-type top silicon layer 303 x Ge 1-x layer 305, the P-type Si x Ge 1-x Layer 305 is grown using selective epitaxy.

[0083] Wherein, the SOI substrate is composed of a bottom silicon layer 301 , a buried oxide layer 302 and a top silicon layer 303 , and both the bottom silicon layer 301 and the top silicon layer 303 are made of single crystal silicon. N-type top silicon layer 303 and P-type Si x Ge 1-x Layer 305 constitutes a SiGe / Si heterojunction diode.

[0084] The manufacturing method of the above-mentioned uncool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com