Electricity storage module and electrically powered vehicle with electricity storage module

A technology for power storage modules and electric vehicles, applied in electric vehicles, battery/battery traction, vehicle components, etc., can solve problems such as large-scale, deformation, and power storage modules are heavy objects, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

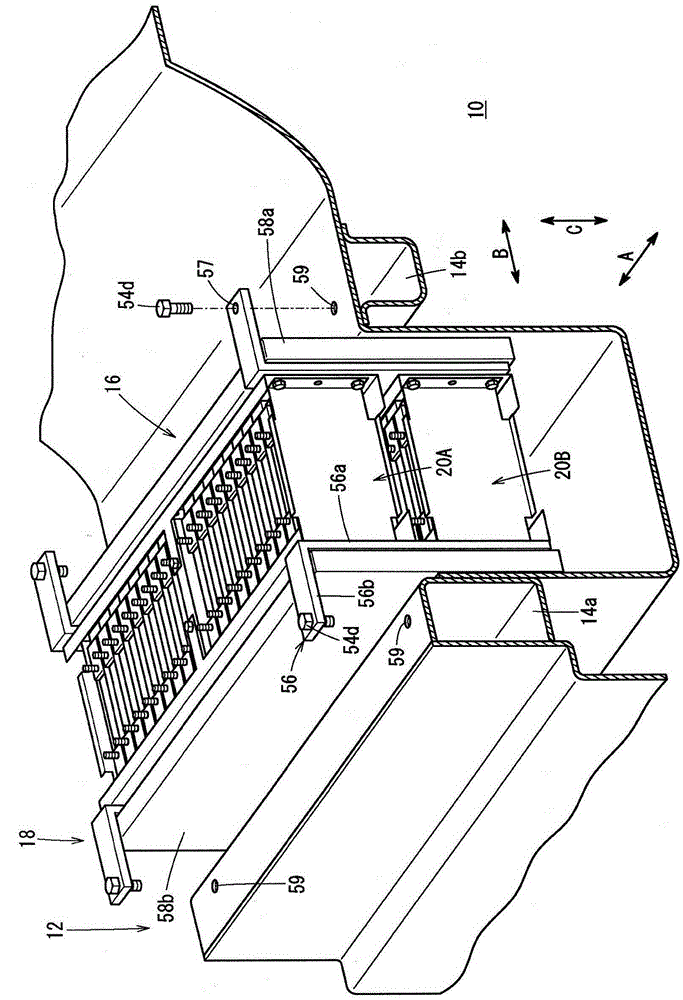

[0030] like figure 1 As shown, an electric vehicle (for example, a hybrid vehicle or EV) 10 according to the first embodiment of the present invention travels by an electric motor (not shown) driven by electric power. A battery pack 16 is mounted on a pair of beams 14 a and 14 b constituting the frame 12 of the electric vehicle 10 via a mounting structure 18 .

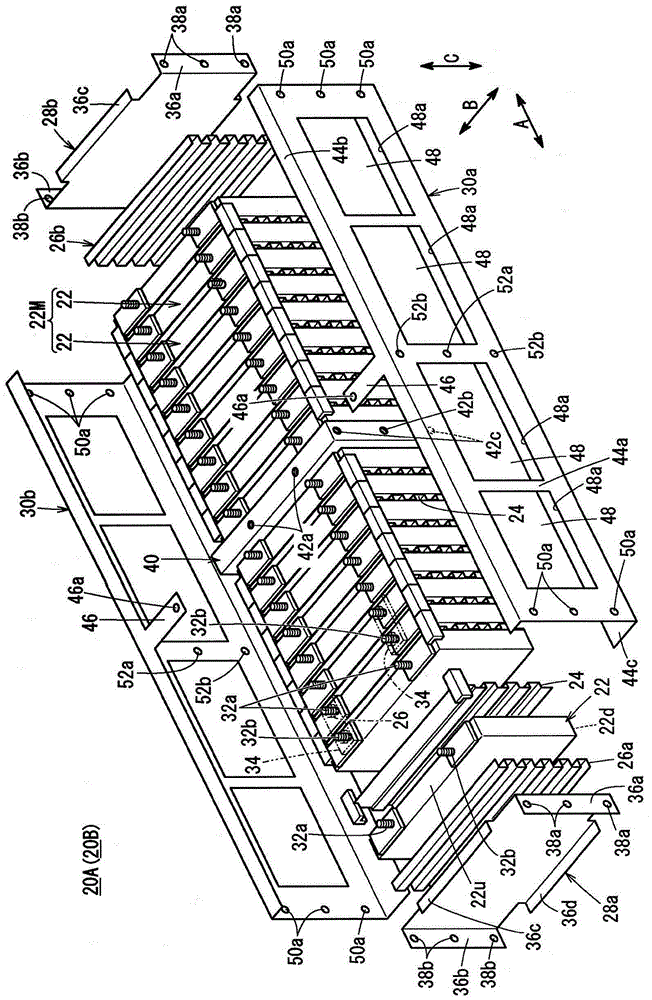

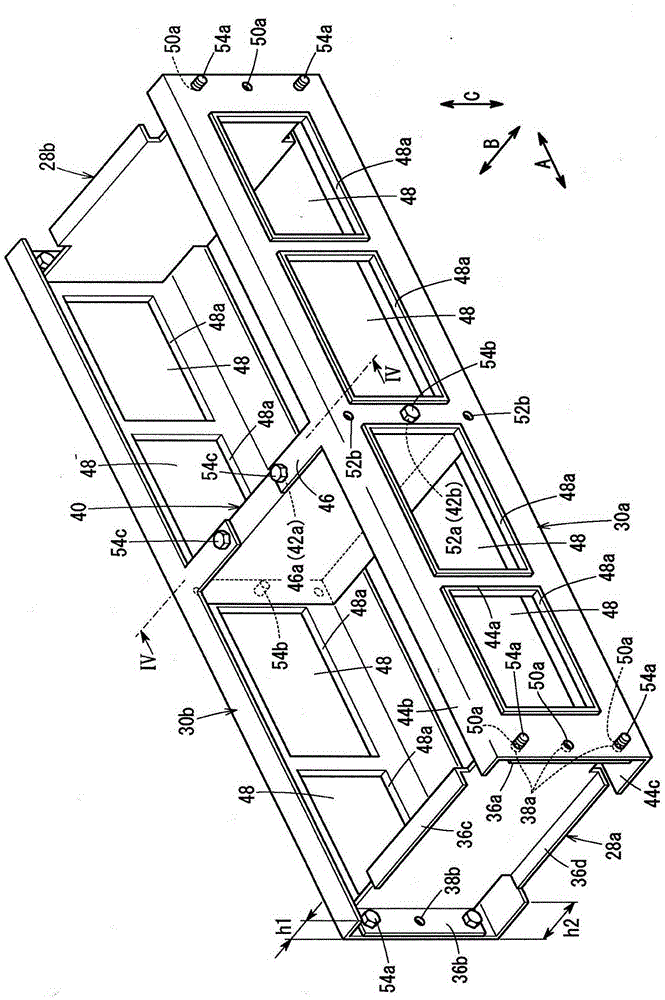

[0031] The battery package 16 includes a plurality of sets, for example, two sets of power storage modules 20A and 20B arranged vertically. The power storage modules 20A and the power storage modules 20B are electrically connected in series. The power storage module 20A has the same configuration as the power storage module 20B. Hereinafter, only the power storage module 20A will be described in detail, and the same components will be assigned the same reference numerals, and detailed descriptions thereof will be omitted. It should be noted that the arrow A direction indicates the vehicle width direction of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com