Novel energy-saving reaction kettle for automatically producing silicone oil

A reaction kettle and silicone oil technology, which is applied in the field of new energy-saving automatic production of silicone oil reactors, can solve the problems of reducing work efficiency, pollution, and the inability to discharge chemical gases casually, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

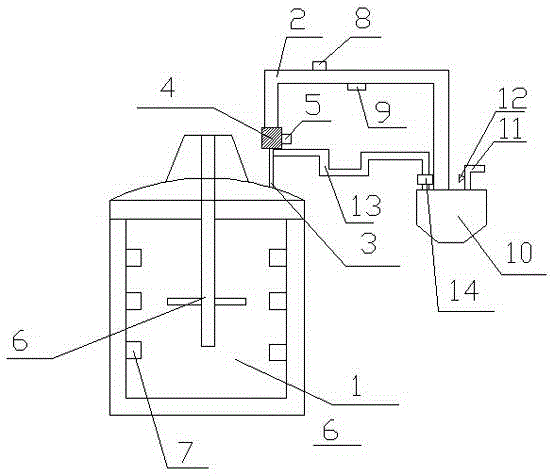

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A new energy-saving and automatic production of silicone oil reaction kettle, including a reaction kettle 1 and a condensation pipe 2, the reaction kettle 1 and the condensation pipe 2 are connected to each other, a connecting pipe 3 is provided between the condensation pipe 2 and the reaction kettle 1, and the connecting pipe 3 is a thin The connecting pipe 3 is provided with a protective pipe 4, the protective pipe 4 is provided with a stainless steel protective net, the protective pipe 4 is provided with a fastener 5, the firm piece 5 is a clamp, and the reactor 1 is provided with an agitator 6, The reaction kettle 1 is equipped with an accelerated stirring device 7, which is a vibrating rod, and the vibrating rod is located on the inner wall of the reaction kettle 1, and the cooling pipe 2 is provided with a cooling member 8, which is a nozzle, and a control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com