Spraying protection device for automobile hub bottom mold

A technology for automobile hubs and protective devices, which is applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc., which can solve the problems of difficult control of coating thickness and uniformity, endangering the health of workers, and sprayed paint scattered in the air and other problems, to achieve the effect of spray coating thickness and uniformity easy to control, novel structure, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

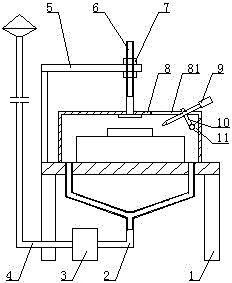

[0007] see figure 1 , the present invention comprises workbench 1, air intake pipe 2, vacuum cleaner 3, air outlet pipe 4, support 5, rotating shaft 6, adjustment nut 7, protective cover 8, spray gun 9, connecting rod 10 and ball hinge 11, the top of described rotating shaft is provided with There are external threads, the upper right corner of the protective cover 8 is provided with an opening 81, the vacuum cleaner 3 communicates with the inner cavity of the protective cover 8 through the air inlet pipe 2, the air outlet pipe 4 is connected with the vacuum cleaner 3, and the bracket 5 is mounted on The upper left part of the workbench 1, the lower part of the rotating shaft 6 is installed in the hole of the protective cover 8, the upper part of the rotating shaft 6 is installed on the bracket 5, and is connected with the bracket 5 through the adjusting nut 7. The ball hinge 11 is contained on the inner wall of the right side plate of protective cover 8, and described connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com