A blanking die for sheet metal parts with high-precision shaft holes

A blanking die, high-precision technology, applied in blanking and punching metal dies for sheet metal parts, and sheet metal forming dies, can solve problems such as inconsistency in size, misalignment of shaft holes, and influence on motor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through the description of non-limiting specific embodiments with reference to the accompanying drawings.

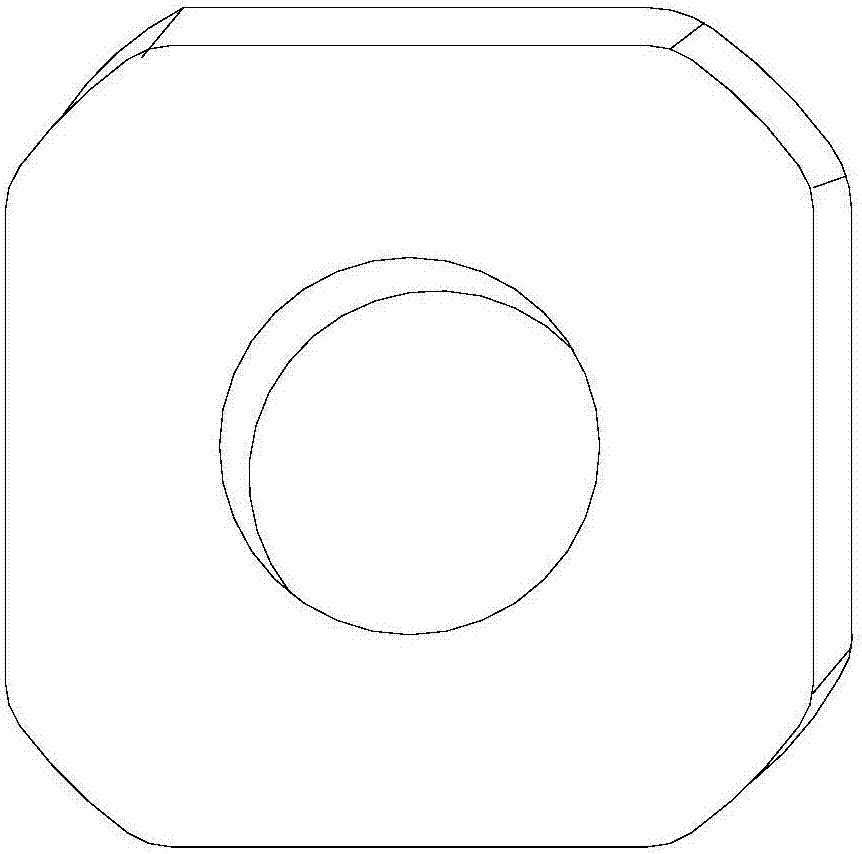

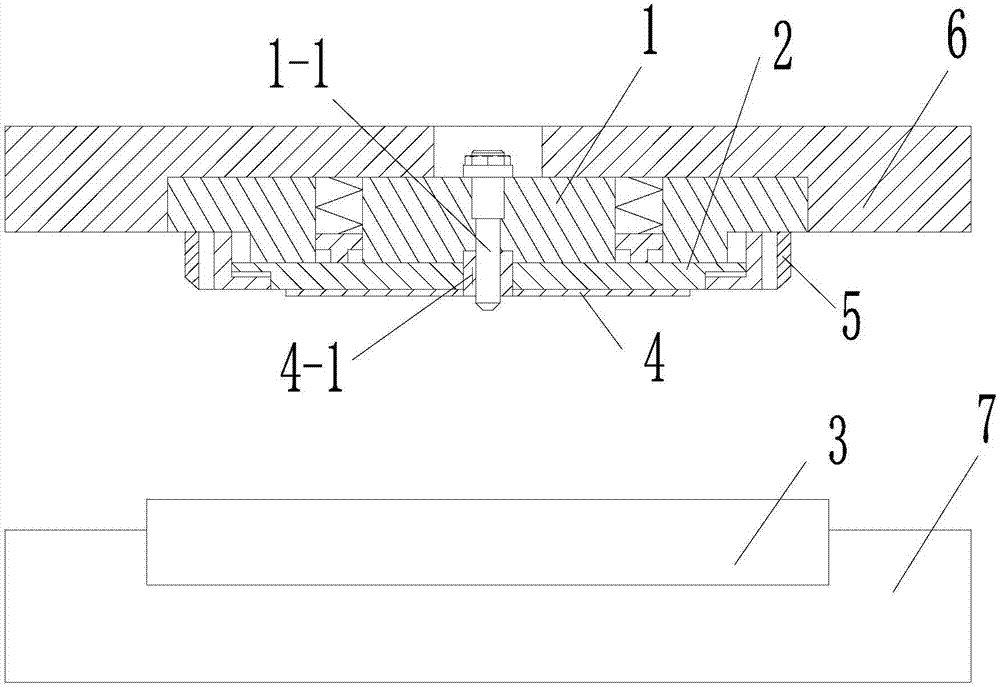

[0024] For a typical implementation, please refer to the attached figure 1 , 2 .

[0025] A blanking die for a sheet material with a high-precision shaft hole, comprising an upper punch 1, a discharge plate 2 elastically configured with the upper punch 1, and a lower die 3; the upper punch 1, the discharge plate 2 and the lower die 3, according to the technical requirements of the workpiece to be processed, are manufactured with the usual technical solutions and cooperate with each other for assembly work, and it:

[0026] There is a compacting plate 4 with a shaft hole 4-1 for compacting the workpiece to be processed on the working surface of the discharge plate 2; and the shape of the compacting plate 4 matches the shape of the workpiece to be processed, and The size of the compaction plate 4 is smaller th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com