Wide-spectrum medium short wave infrared Dewar window based on silicon substrate and preparation process

A wide-spectrum, silicon-based technology, applied in optics, optical components, instruments, etc., can solve the problems of metallization process research difficulties, absorption affecting channel optical efficiency, etc., to eliminate the influence of water vapor absorption, improve reliability, and stabilize product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

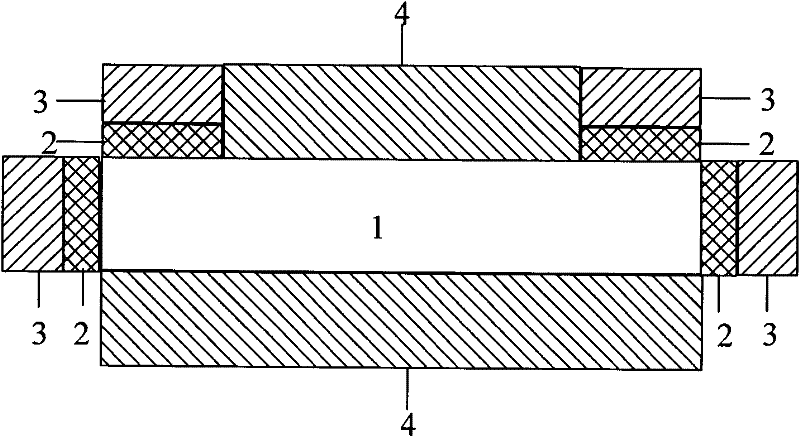

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The concrete technical index requirement of the embodiment of the present invention is:

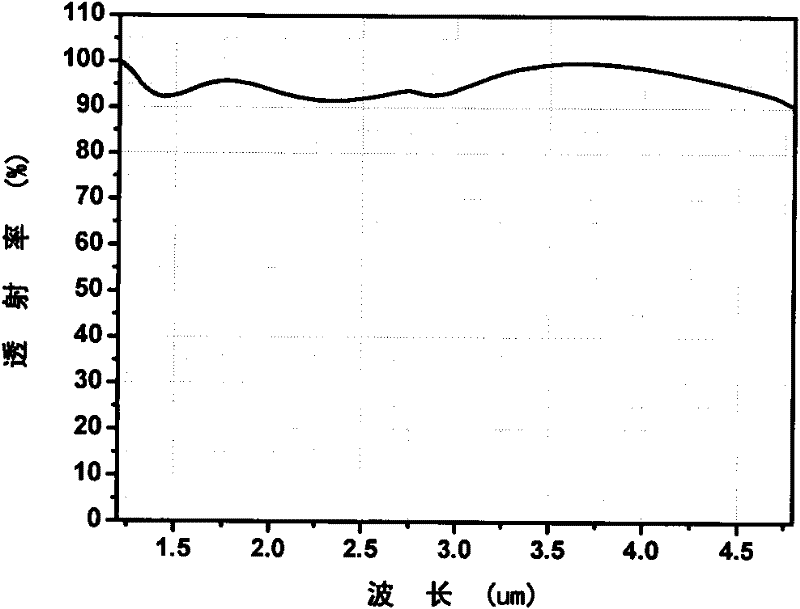

[0026] 1.2-4.8um, the average transmittance is greater than 93%; the thickness of the metallization layer is greater than 1um; the base material is silicon.

[0027] According to the technical requirements and the physical characteristics of various thin films, first determine the development sequence of each part. Since the metallization process requires the process of mask protection and mask removal, in order to prevent the performance of the infrared dielectric film from being affected, it is necessary to perform metallization first. After the metallization is completed, the gold layer is fully aged to carry out the development of the next step of the dielectric anti-reflection coating.

[0028] Considering the influenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com