A high-precision shaft hole punching die for sheet metal parts

A punching die, high-precision technology, applied in the field of sheet metal parts forming die, metal sheet metal parts high-precision shaft hole punching metal die field, can solve the problem of inconsistent size, affecting the quality of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the present invention in detail through the description of specific embodiments with reference to the accompanying drawings, but is not limited thereto. Other technical solutions proposed by adopting the technical concept of the present invention all belong to the protection scope of the present invention.

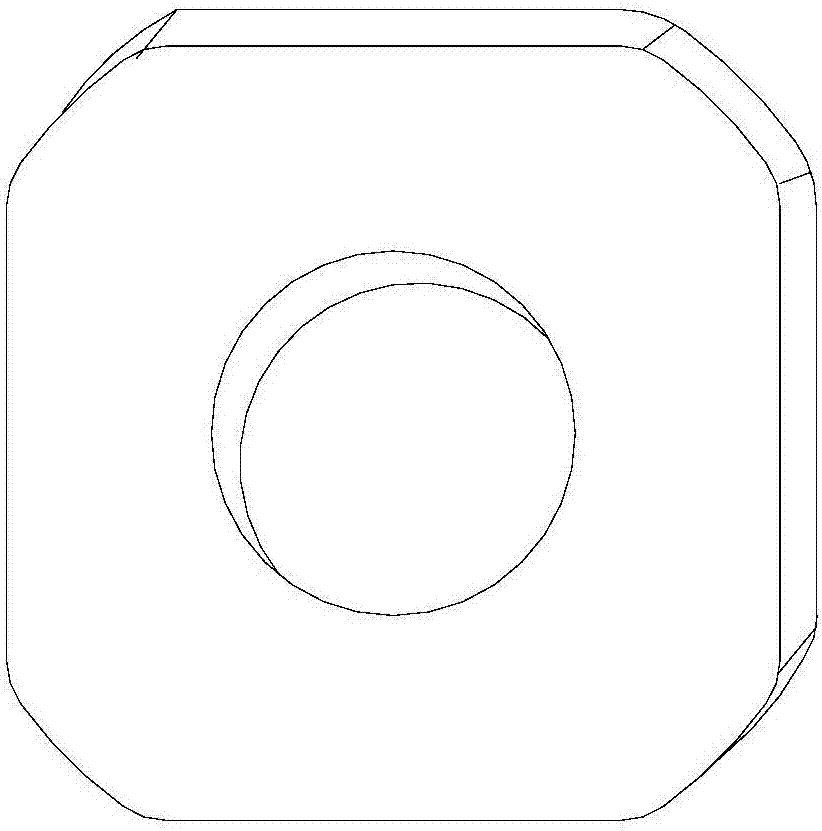

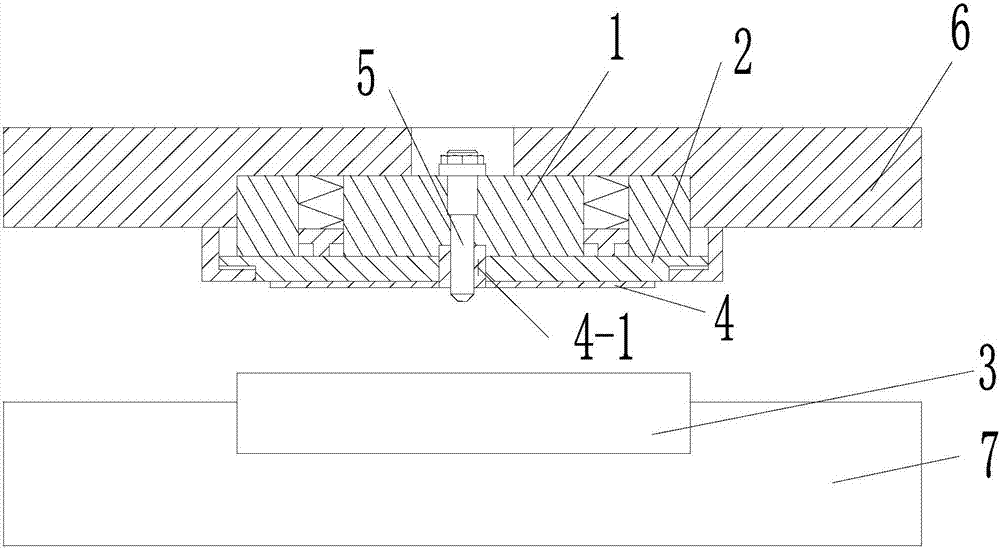

[0023] A typical specific implementation, as attached figure 1 , 2 as shown,

[0024] A high-precision axial hole punching die for sheet metal parts, including an upper punch 1, a discharge plate 2 elastically configured with the upper punch 1, and a lower die 3; the upper punch 1, the discharge plate 2 and the lower die Die 3, according to the technical requirements of the workpiece to be processed, is manufactured using common technical solutions and cooperates with each other for assembly work, and its:

[0025] There is a compacting plate 4 with a through hole 4-1 for compacting the workpiece to be processed on the working surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com