Clamping device for bar grabbing

A technology of clamping device and bar material, which is applied in the direction of workpiece clamping device, positioning device, clamping, etc., can solve the problems of high economic cost, potential safety hazard, waste of energy, etc., to improve operation safety, save economic cost, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

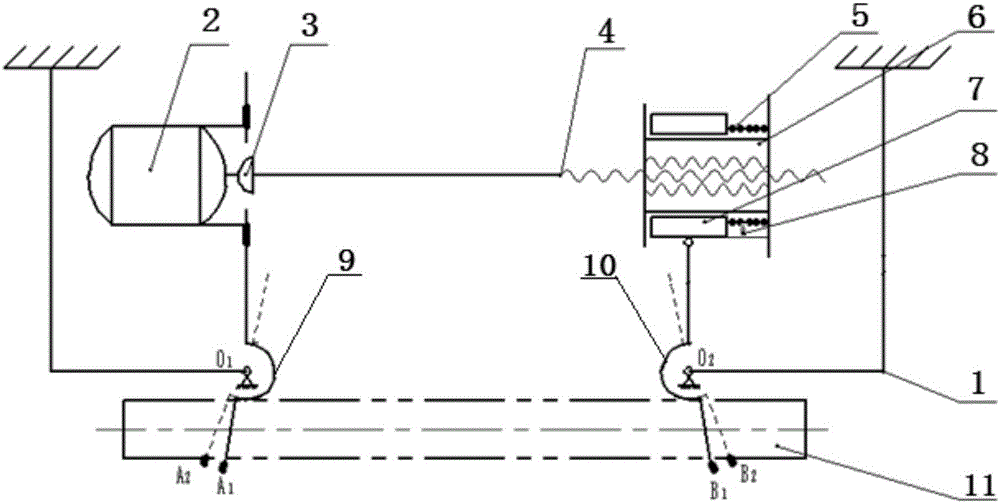

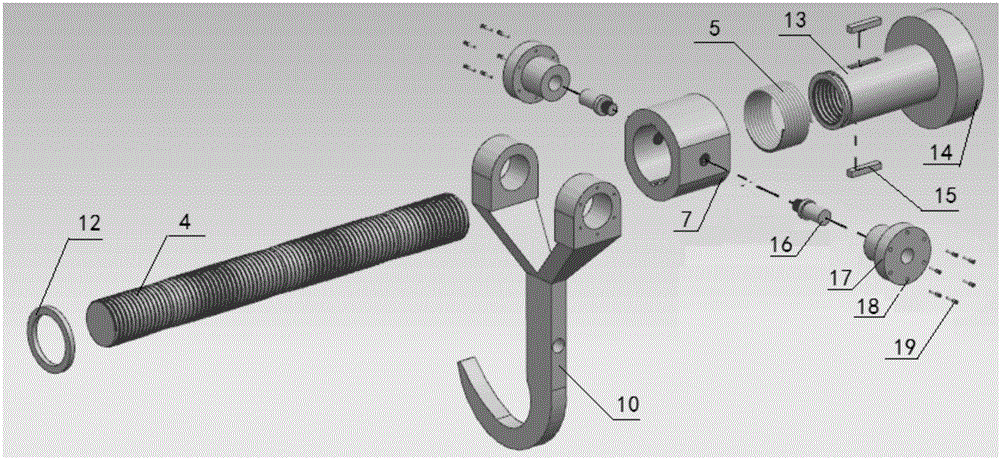

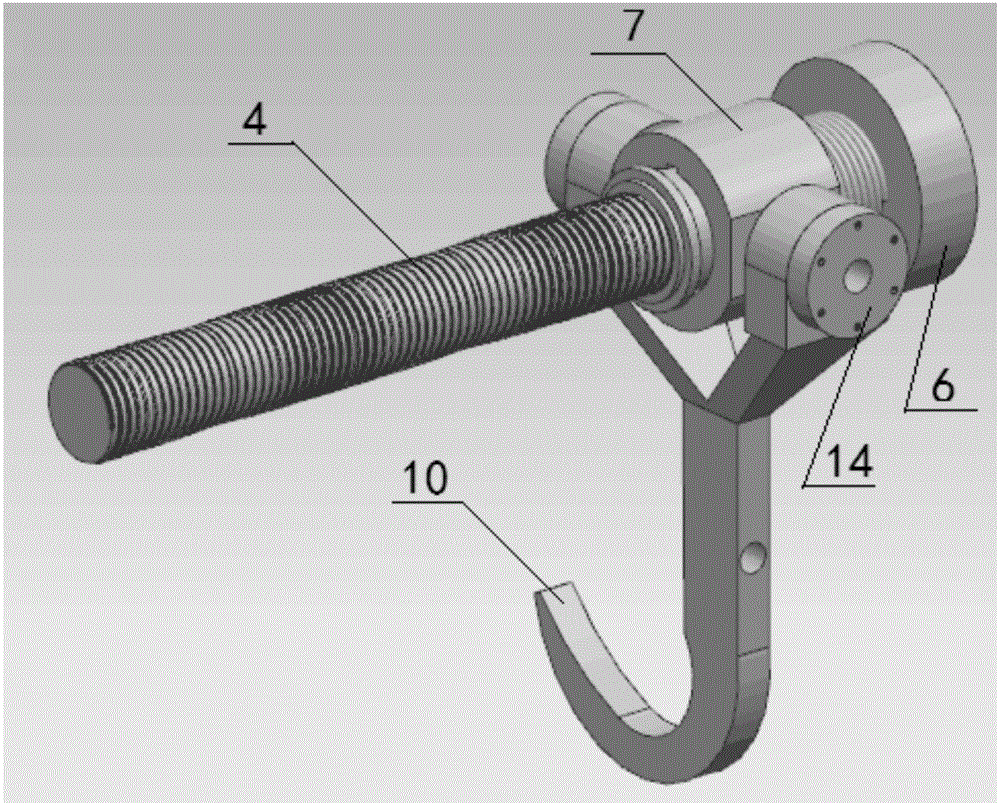

[0018] Example: Such as figure 1 As shown, the present invention discloses a clamping device for grabbing bars, including a frame 1, a driving motor 2, a linkage device, a first claw 9 and a second claw 10, and the driving motor 2 and the linkage device are fixed on the on the above-mentioned frame 1, and the transmission is realized through the screw rod 4; the linkage device includes the swing guide sleeve 7 and the anti-rotation / slip nut 6, the anti-rotation / slip nut 6 includes a threaded mating end 13 and a nut 14, and the anti-rotation A pair of keys 15 are provided on the outer wall of the threaded mating end 13 of the sliding nut 6, and a through groove is provided at the corresponding position on the inner wall of the swing guide sleeve 7, and the swing guide sleeve 7 is sleeved on the anti-rotation / slip joint through the key connection. On the threaded mating end of the nut 6, this structure can realize the relative sliding between the anti-rotation / slip nut 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com