Car-mounted tool cabinet

A vehicle-mounted toolbox and toolbox technology, applied in the direction of manufacturing tools, workshop equipment, etc., can solve the problems of increased labor intensity, long operation time, easy damage, etc., and achieve the effect of reducing labor intensity, speeding up construction progress, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

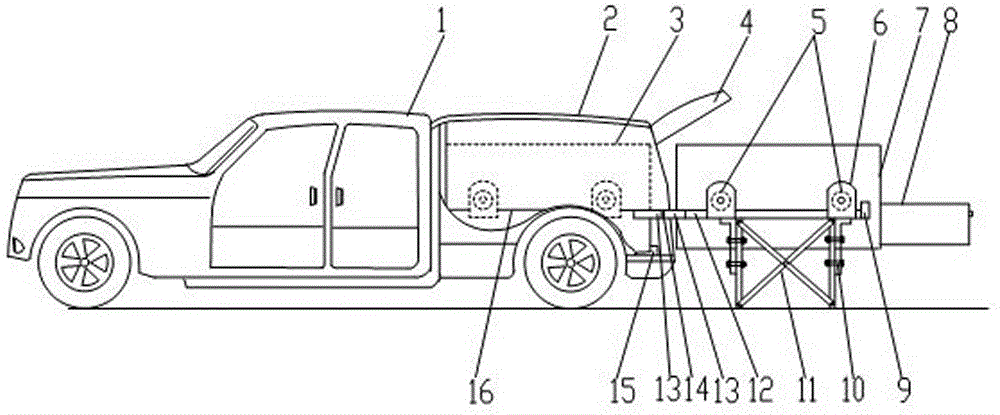

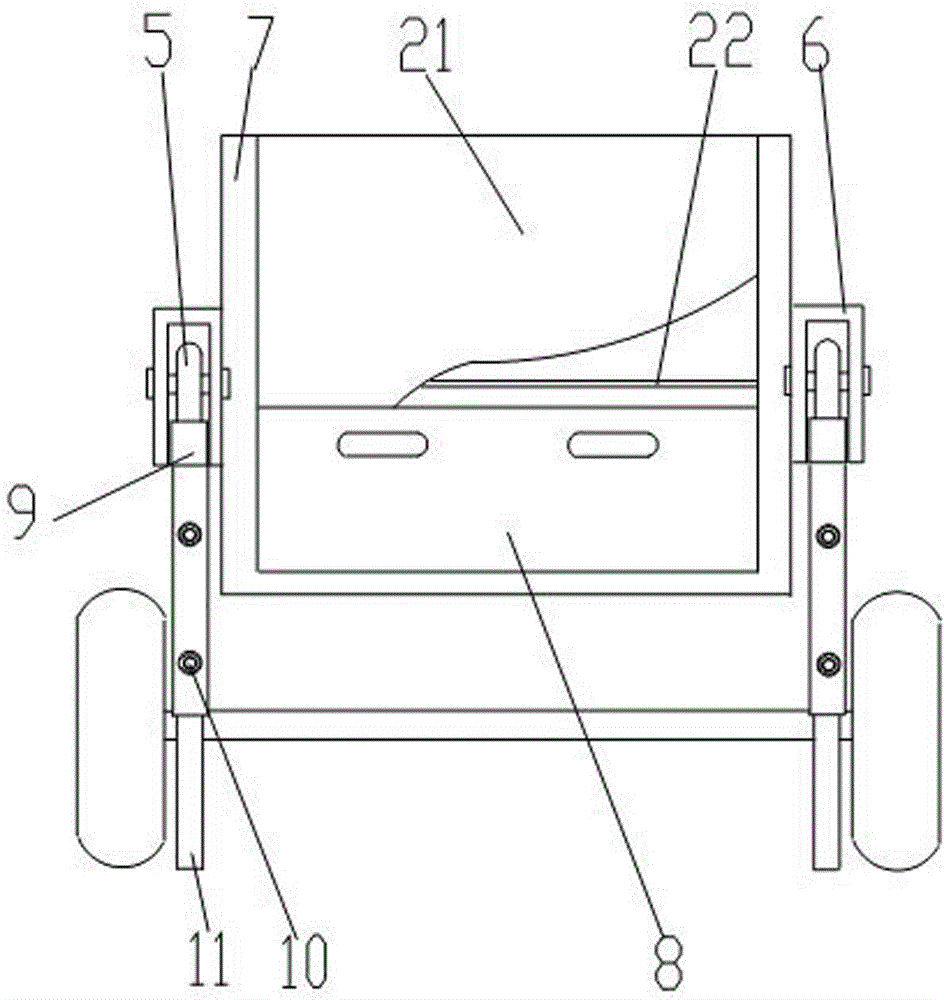

[0014] Embodiment 1: A kind of vehicle toolbox, comprises tool box 7, fixed guide rail 16, docking guide rail 12 and support frame 11; Described fixed guide rail 16 has two and is symmetrically installed in the maintenance car trunk 2, and described docking guide rail 12 has two and is respectively provided with movable supporting frame 11, and the left end of docking guide rail 12 is docked with the right end of fixed guide rail 16, and the box shell both sides of described tool box 7 is provided with symmetrical roller 5, and described roller 5 can be on fixed guide rail Roll between 16 and docking rail 12. Described tool box 7 is provided with lower drawer 8, and described lower drawer 8 is provided with handle and is positioned on the guide rail of tool box 7 inner bottom, is provided with bottom plate 22 between the tool box 7 inwalls above lower drawer 8 to form opening toward Tool box 21 on. It also includes a limit block 9 and a mandrel 14. There are two limit blocks ...

Embodiment 2

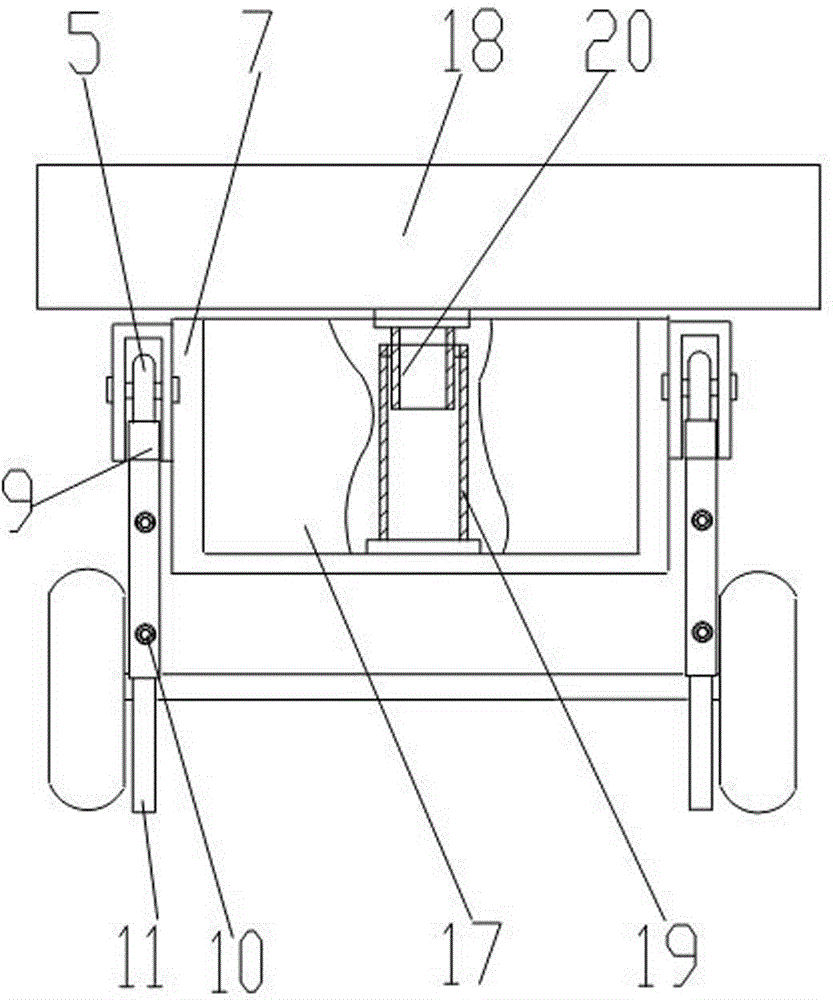

[0016] Embodiment 2: A kind of vehicle toolbox, comprises toolbox 7, fixed guide rail 16, docking guide rail 12 and support frame 11; Described fixed guide rail 16 has two and is symmetrically installed in the maintenance car trunk 2, and described docking guide rail 12 has two and is respectively provided with movable supporting frame 11, and the left end of docking guide rail 12 is docked with the right end of fixed guide rail 16, and the box shell both sides of described tool box 7 is provided with symmetrical roller 5, and described roller 5 can be on fixed guide rail Roll between 16 and docking rail 12. The tool box 7 is provided with a fixed box 17 and a rotating box 18, the fixed box 17 is located at the bottom of the tool box 7, the rotating box 18 is located above the fixed box 17, and is connected by a flange on the bottom plate inside the fixed box 17 The outer sleeve 19 is connected to the inner sleeve 20 through a flange under the bottom plate outside the rotary b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap