Logistics sorting robot mechanism based on hybrid

A robot and series mechanism technology, applied in sorting, manipulator, program control manipulator, etc., can solve the problem that the logistics sorting robot mechanism cannot meet the requirements of automatic sorting work, and can meet the requirements of automatic operation, high positioning accuracy, The effect of a large workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

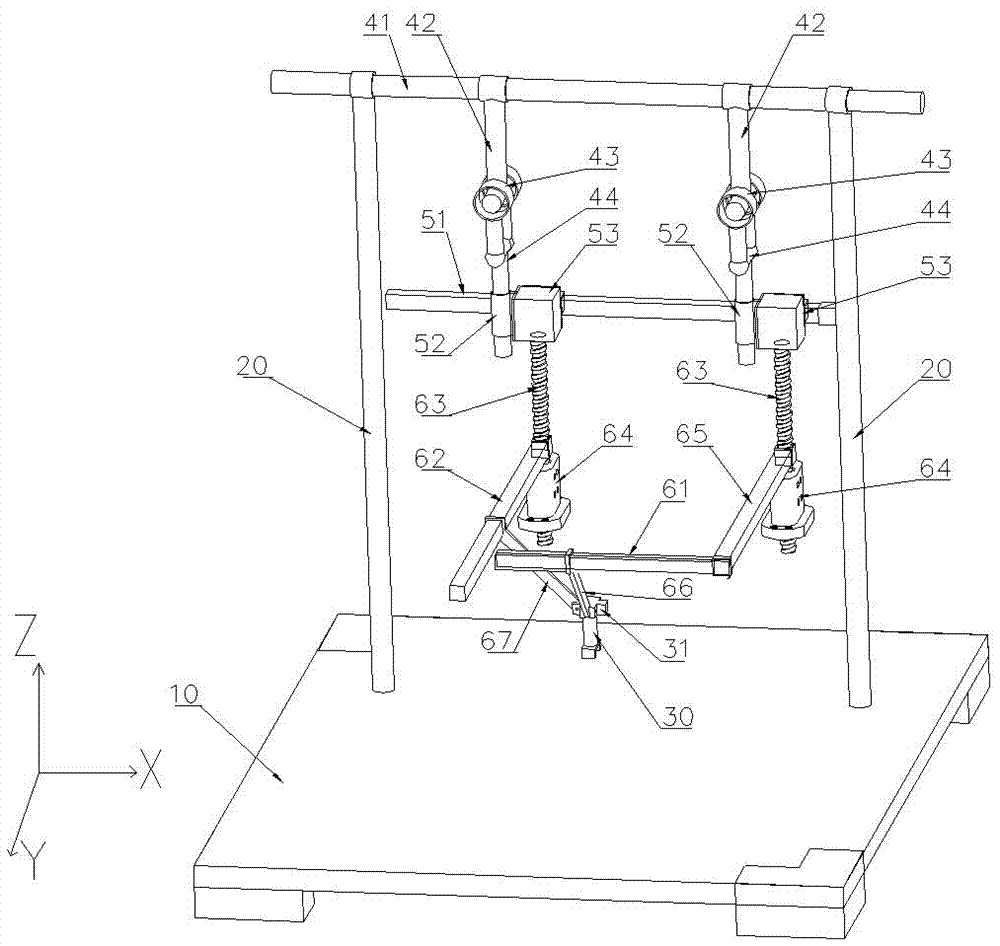

[0014] See figure 1 , the logistics sorting robot mechanism based on the hybrid connection of the present invention includes a bottom plate 10, a bracket 20, a manipulator 30, a two-degree-of-freedom series mechanism and a three-degree-of-freedom parallel mechanism, and the bottom plate 10 is vertically fixed with mutual Two parallel supports 20.

[0015] The series mechanism includes a fixed round rod 41, which is arranged along the X-axis and installed on two brackets 20. Two vertical rods 42 are rotatably suspended on the fixed round rod 41, and the bottoms of the two vertical rods 42 are respectively A group of rotating rods 44 are connected through the rolling bearings 43; and the rolling bearings 43 are arranged on the bottom of the vertical rods 42 along the Y axis, so that the rolling bearings 43 can be used as a rotating pair to realize the rotating rods 44 rotating around the Y axis.

[0016] The connecting structure includes a cross bar 51 and a sleeve 52 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com