Motor rotor automatic sorting and feeding device

A technology of motor rotor and automatic sorting, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of slow production takt, difficult to guarantee good product rate, low efficiency of loading and unloading, etc., and achieve low production costs. , the effect of large compatibility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

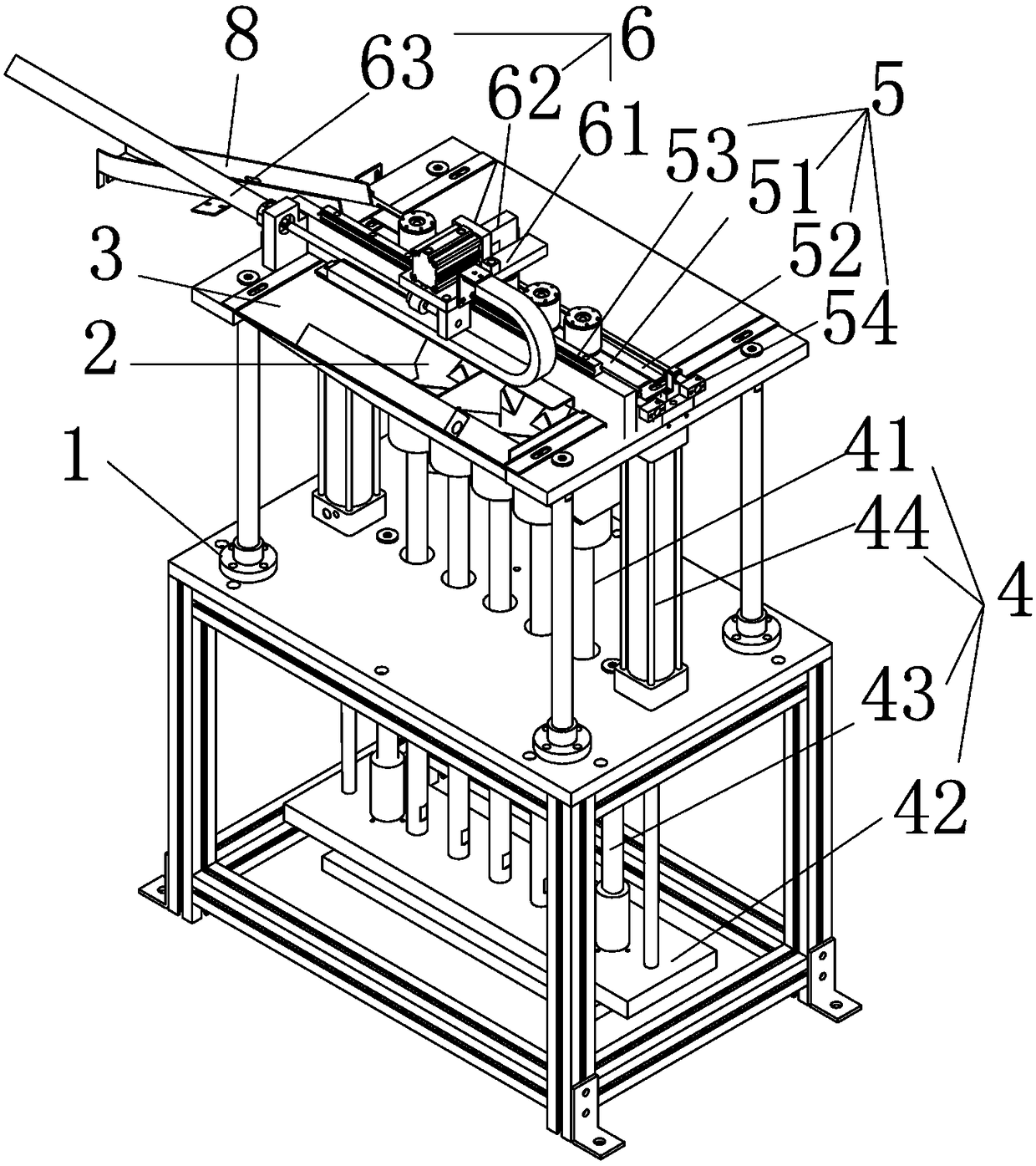

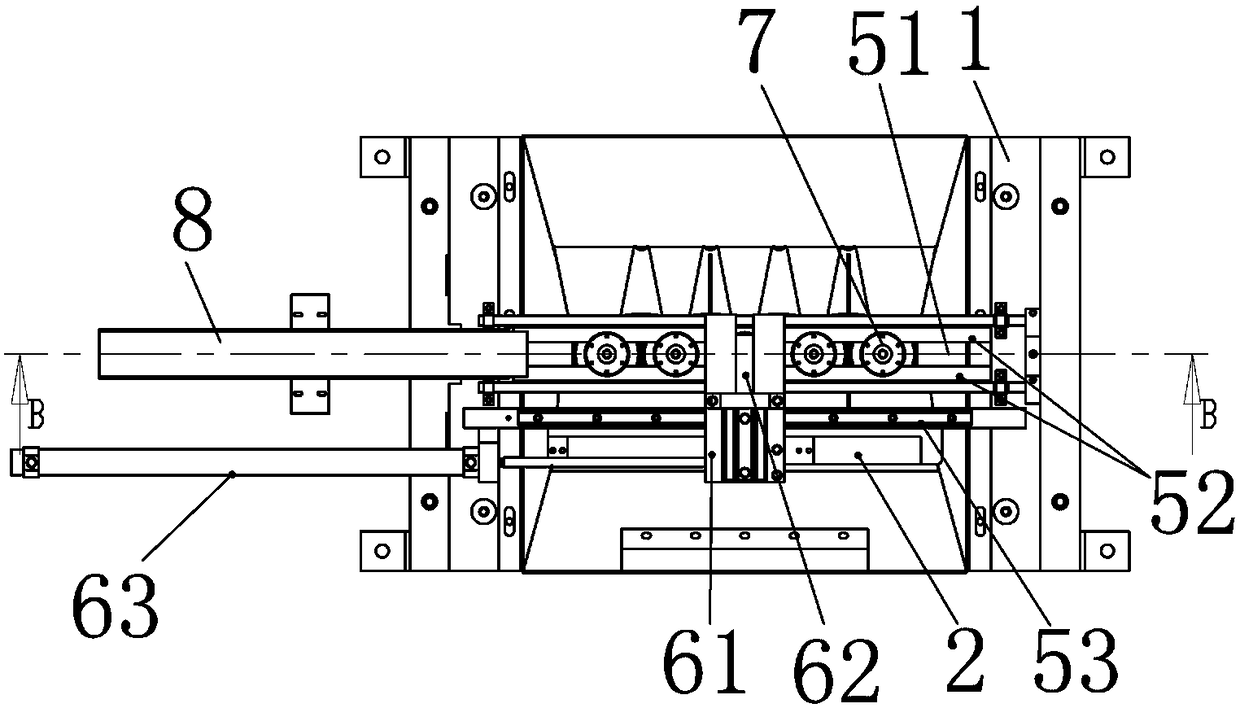

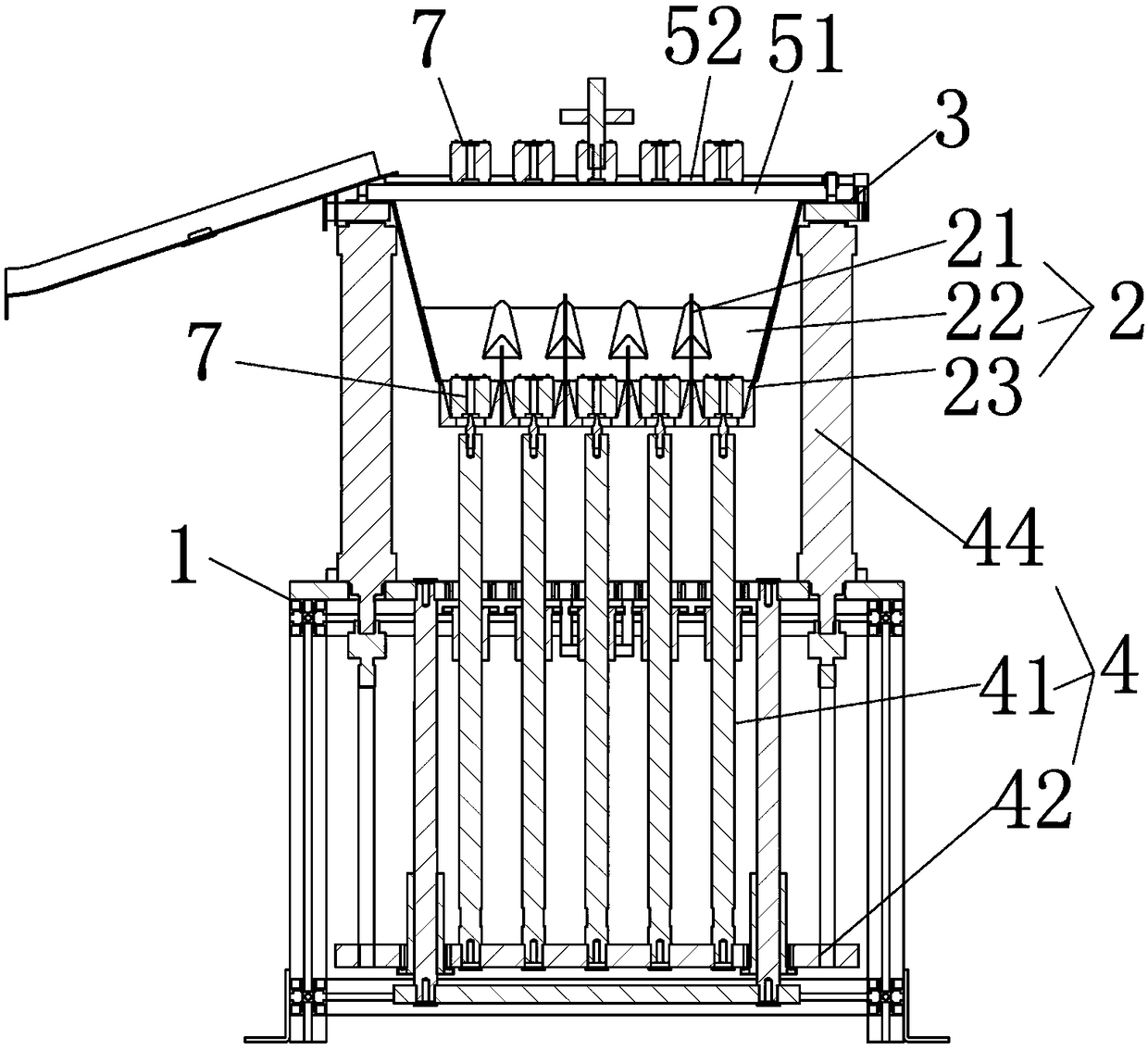

[0017] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An automatic sorting and feeding device for motor rotors, characterized in that it includes a frame 1 and a hopper 2 above it, a workbench 3, a rotor feeder 4, a rotor guide groove 5 and a rotor pusher 6, in:

[0018] The cross-section of the hopper 2 is trapezoidal with a large top and a small bottom, and is divided into several discharge ports 22 by a partition 21, and the motor rotor 7 enters the inlet at the bottom of the discharge port 22 one by one under the action of the discharge port 22. Inside the feed port 23;

[0019] The rotor loader 4 includes a thimble 41 arranged below the feed port 23 and a lifting slide 42 that drives it to move up and down. When the lift slide 42 pushes the thimble 41 to move upward, it drives the motor on the feed port 23 The rotor 7 rises to the working table;

[0020] The rotor feed chute 5 includes a feeding tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com