A method of converting oil-soluble nanoparticles into water-soluble nanoparticles

A nanoparticle, oil-soluble technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems affecting the dispersion of nanoparticles and other physical and chemical properties, achieve the retention of physical and chemical properties, and the preparation method is simple and easy Line, overcome the effect of long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

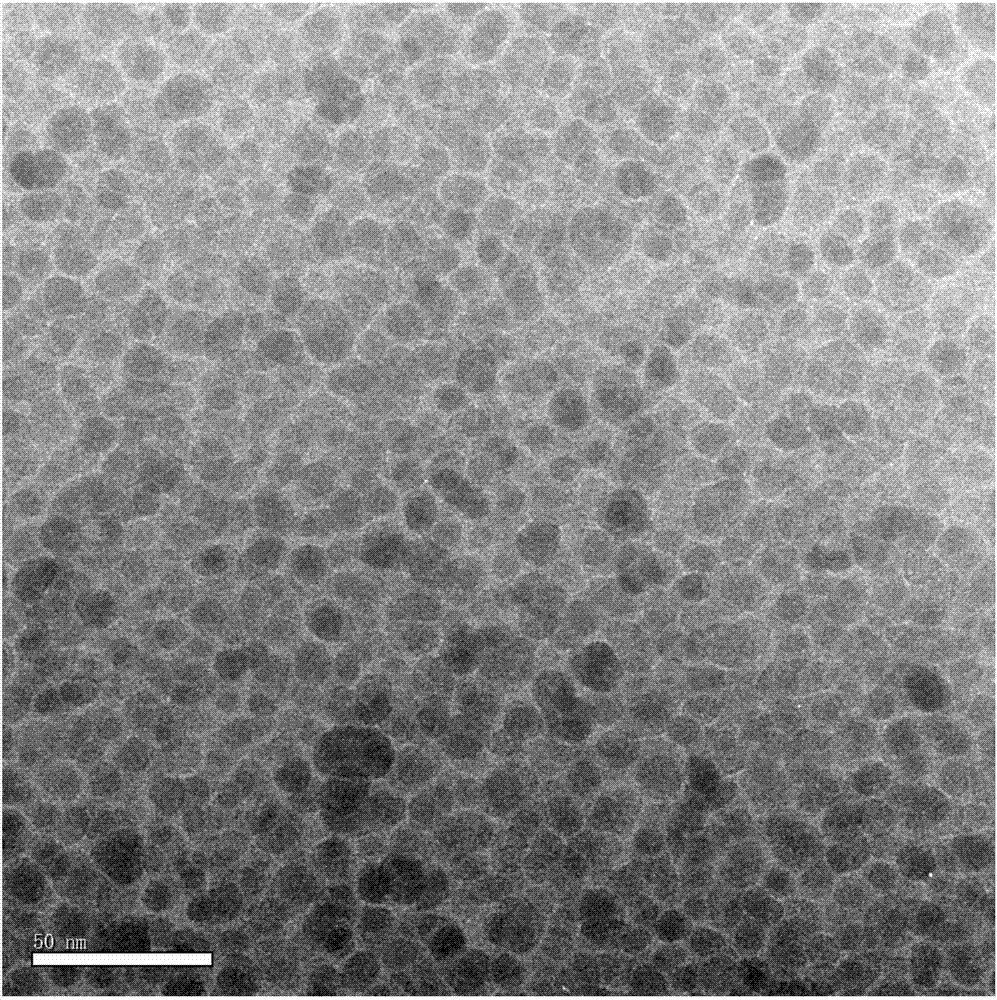

[0023] Dissolve 0.2 g of polyethylene glycol phosphate in 3 mL of tetrahydrofuran, and mix this solution with 10 mg / mL of oleic acid-coated Fe 3 o 4 The toluene solution of nanoparticles was mixed, and 5 mL of ether was added to the above solution, and stirred for 2 min. Add 10mL of deionized water to the above solution, stir for 10min and let it stand for 10min, then use a separatory funnel to separate the liquid, take the lower layer solution and perform rotary evaporation to remove the organic solvent to obtain a water-soluble Fe 3 o 4 Nanoparticle solution, add 10mL ethanol to this solution, centrifuge and vacuum dry to obtain water-soluble Fe 3 o 4 Nanoparticle powder.

example 2

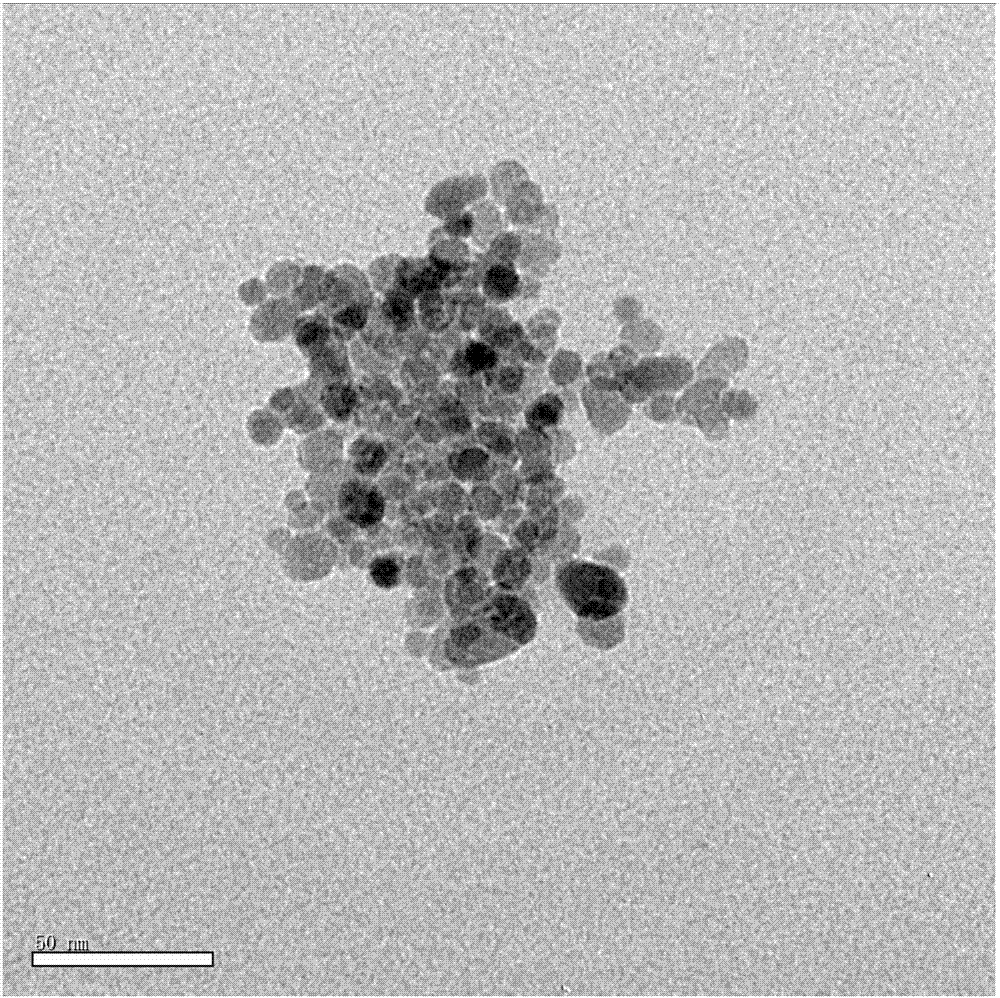

[0025] Dissolve 0.2 g of polyethylene glycol phosphate in 5 mL of tetrahydrofuran, and mix this solution with 10 mg / mL of oleic acid-coated NaYF 4 : Yb, Er nanoparticles n-hexane solution mixed, 10mL of ether was added to the above solution, stirred for 2min. Add 10 mL of deionized water to the above solution, stir for 3 minutes and let it stand for 10 minutes, then use a separatory funnel to separate the liquid, take the lower layer solution and perform rotary evaporation to remove the organic solvent to obtain water-soluble NaYF 4 : Yb, Er nanoparticle solution, add 10mL ethanol to this solution, obtain water-soluble NaYF after centrifugal separation, vacuum drying 4 : Yb, Er nanoparticle powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com