Method for preparing nano beta-TCP powder through macromolecular network gelling method and nano beta-TCP powder

A technology of polymer network and gel method, which is applied in the field of biomedical ceramic powder to prevent phase separation and dispersion, overcome long reaction time and fast synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 0.02mol of calcium nitrate tetrahydrate and citric acid and dissolve them in 100mL of deionized water, stir well, add 0.013mol of diammonium hydrogen phosphate according to the molar ratio of Ca / P=1.5, and use nitric acid and ammonia water as pH regulator, to control the pH of the mixture to 2-3;

[0039] (2) Add 5g of acrylamide, 1g of N,N'-methylenebisacrylamide, 0.1mL of tetramethylethylenediamine and 0.4g of ammonium persulfate to the mixture in step (1) in sequence, and stir well ;

[0040] (3) Treat the mixed solution in step (2) in a water bath, the temperature of the water bath is 80° C., and the time of the water bath is 30 min, to obtain a transparent hydrogel;

[0041] (4) Pre-freeze the wet gel obtained in step (3) in a -20°C refrigerator, and then freeze-dry until the quality of the gel is stable, then directly heat-treat the dry gel at 850°C for 180 minutes to obtain nano-scale β-TCP powder.

Embodiment 2

[0043] (1) Weigh 0.03mol of calcium nitrate tetrahydrate and citric acid and dissolve them in 100mL of deionized water, stir evenly, add 0.02mol of diammonium hydrogen phosphate according to the molar ratio of Ca / P=1.5, and use nitric acid and ammonia water as pH regulator, to control the pH of the mixture to 2-3;

[0044] (2) Add 16g of acrylamide, 2g of N,N'-methylenebisacrylamide, 0.2mL of tetramethylethylenediamine and 0.5g of ammonium persulfate to the mixture in step (1) in sequence, and stir well ;

[0045] (3) Treat the mixed solution in step (2) in a water bath, the temperature of the water bath is 70° C., and the time of the water bath is 60 minutes to obtain a transparent hydrogel;

[0046] (4) Pre-freeze the wet gel obtained in step (3) in a -20°C refrigerator, and then freeze-dry until the quality of the gel is stable, then directly heat-treat the dry gel at 1000°C for 120 minutes to obtain nano-scale β-TCP powder.

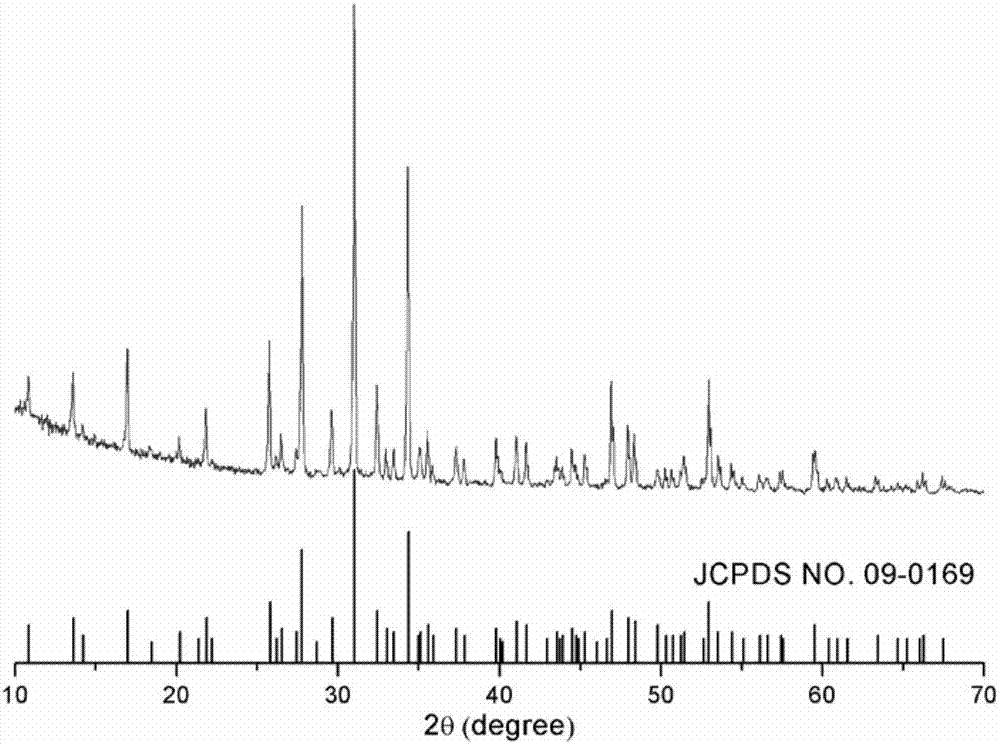

[0047] For the powder X-ray diffraction anal...

Embodiment 3

[0049] (1) Weigh 0.045mol of calcium nitrate tetrahydrate and citric acid and dissolve them in 100mL of deionized water, stir evenly, add 0.03mol of diammonium hydrogen phosphate according to the molar ratio of Ca / P=1.5, and use nitric acid and ammonia water as pH regulator, to control the pH of the mixture to 2-3;

[0050] (2) Add 33g of N-methylolacrylamide, 3g of N,N'-methylenebisacrylamide, 0.3mL of tetramethylethylenediamine and 0.6g of 3% hydrogen peroxide, and stir well;

[0051](3) Treat the mixed solution in step (2) in a water bath, the temperature of the water bath is 85° C., and the time of the water bath is 40 minutes to obtain a transparent hydrogel;

[0052] (4) Microwave-dry the wet gel obtained in step (3) until the quality of the gel is stable, and then directly heat-treat the dry gel at 800° C. for 160 min to obtain nano-sized β-TCP powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com