Turned edge removing, ironing and setting machine for large scarf

A setting machine and edge curling technology, which is applied in the direction of fabric edge trimming, textile and papermaking, and fabric surface trimming, can solve the problems of low efficiency, troublesome ironing, and reduced efficiency of ironing, and achieve good curling effect and use Convenience and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

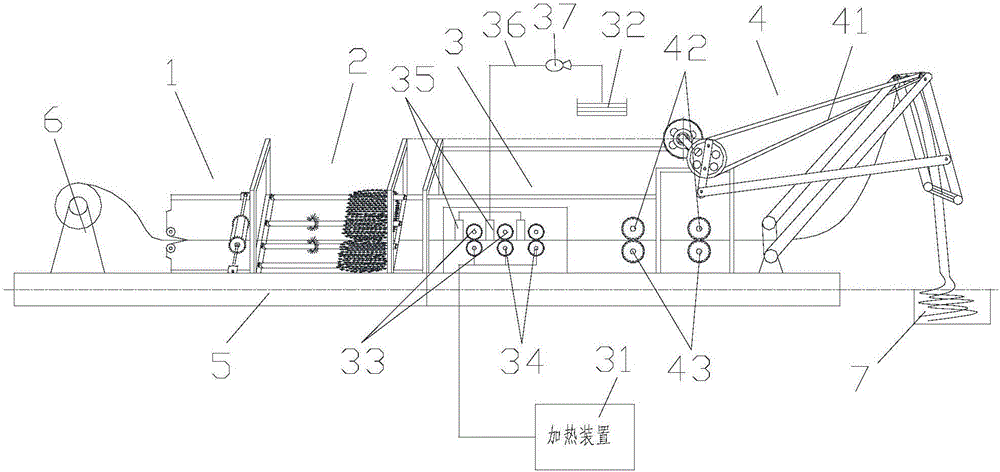

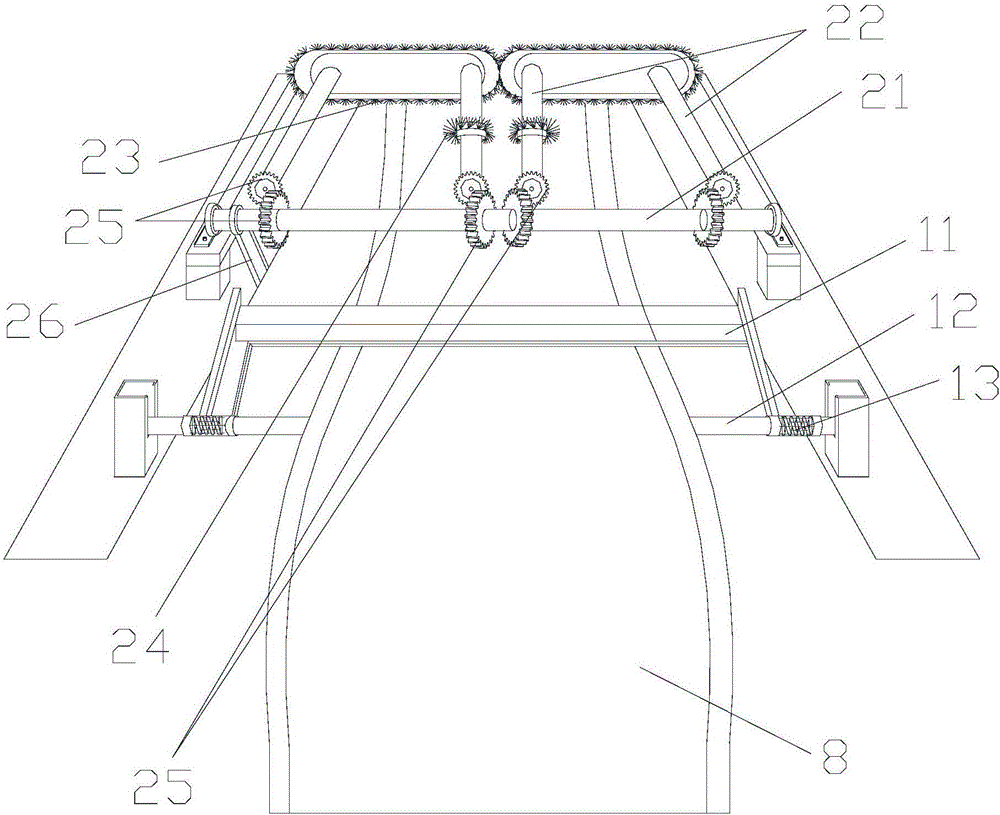

[0012] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention includes an introduction device 1, a de-curling device 2, a ironing device 3, and an output device 4. On the frame 5, a blank frame 6 is placed in front of the introduction device 1, and a feeding box 7 is placed behind the output device 4; The feeding roller 12 is provided with a towel presser 11 through an elastic device 13; the de-curling device 2 is composed of a driving shaft 21, a driven shaft 22, a crawler brush 23, and a rolling brush 24, and the driving shaft 21 is horizontally installed on the On the frame 5, the driven shaft 22 is vertically installed on the frame 5, the driving shaft 21 and the driven shaft 22 are connected and driven by a bevel gear 25, and the crawler brush 23 and the rolling brush 24 are installed on the driven shaft 22. The driving shaft 21 is connected to the motor through a belt 26; the ironin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com