Room type goaf filling method

A technology for gobs and filling stations, which is applied to fillings, mining equipment, earthwork drilling and mining, etc., to achieve the effects of increasing coal recovery rate, convenient operation, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

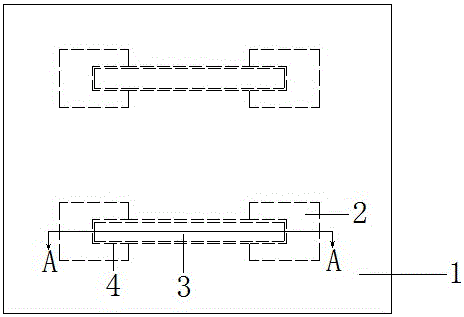

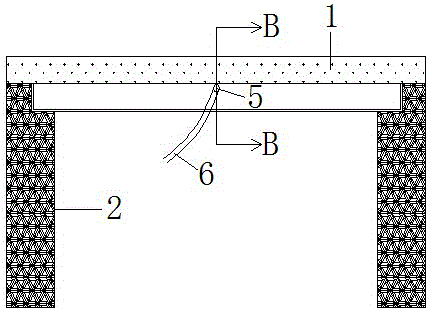

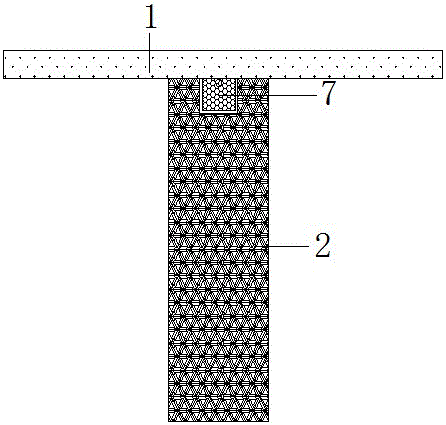

[0032] Taking two adjacent coal pillars in the goaf as an example, as shown in figure 1 In the above, at the position where the coal pillar 2 of the goaf is in contact with the overlying roof 1 of the goaf, a groove 4 is excavated on the coal pillar. The shape of the groove is a cuboid; the groove is located at the top of the coal pillar with a rectangular section , the length of the groove is 1 / 2 of the rectangular long side of the coal pillar, the width of the groove is 1 / 3 of the rectangular wide side of the coal pillar, and the height of the groove is equal to its width, so that the support structure formed in this way has high stability.

[0033] Do the same work on another adjacent coal pillar. During this period, in order to prevent the roof from falling, a metal mesh false roof can be arranged in the construction area to ensure construction safety.

[0034] A grouting groove 3 is set above the adjacent coal pillars where two grooves have been excavated, and a grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com