Corrosion rate measuring device and measuring method

A corrosion rate and measuring device technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of inability to maintain or replace metal components, inability to know the corrosion degree of metal components in time, and inability to measure metal component corrosion in real time Speed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

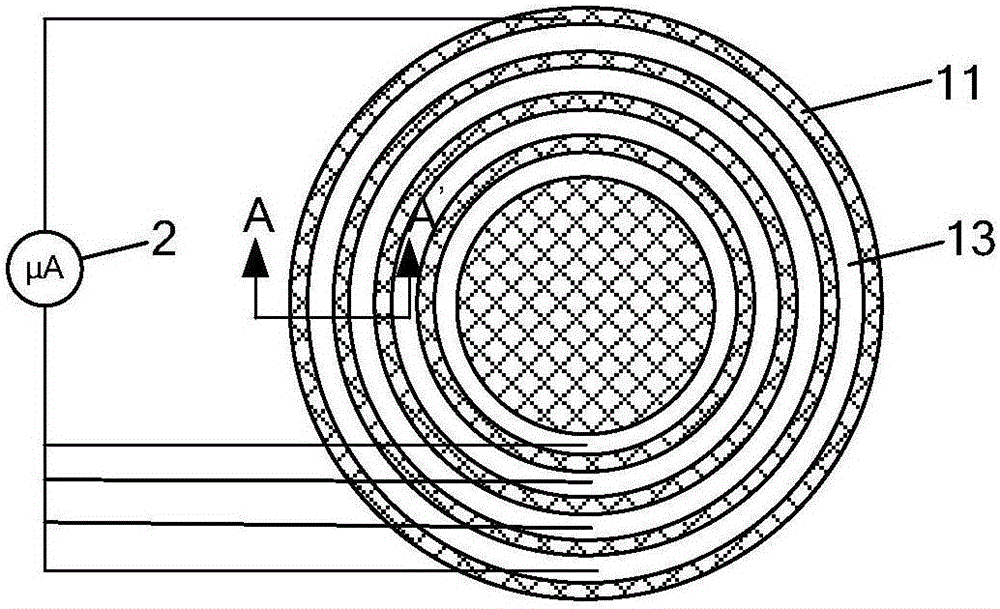

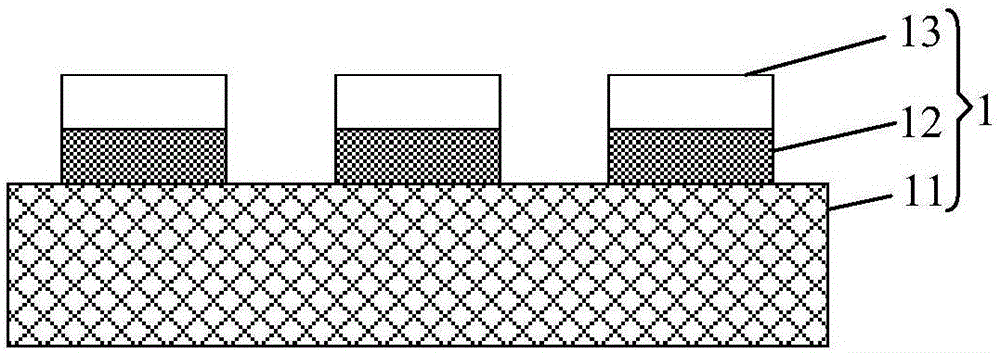

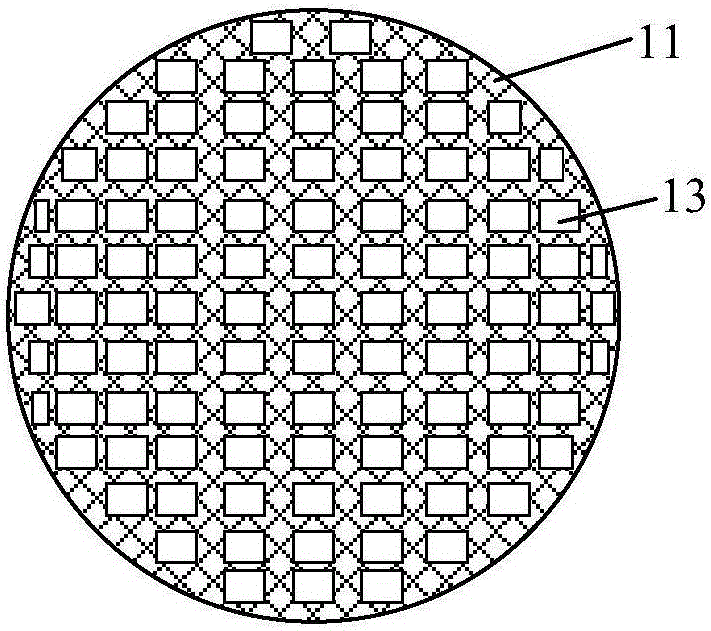

[0025] Embodiments of the present invention provide a corrosion rate measuring device, such as figure 1 As shown, the corrosion rate measuring device includes at least one measuring probe 1 and at least one ammeter 2, specifically, as figure 2 As shown, the measuring probe 1 includes a substrate 11, an insulating layer 12 and a metal layer 13; wherein, the insulating layer 12 is located on the substrate 11, the metal layer 13 is located on the insulating layer 12, and the projection of the insulating layer 12 and the metal layer 13 on the substrate 11 All fall in the substrate 11, the negative terminal of the ammeter 2 is connected to the substrate 11, and the positive terminal of the ammeter 2 is connected to the metal layer 13; the substrate 11 is an active metal or an active metal alloy; the metal layer 13 is an inert metal layer.

[0026] The process of using the above corrosion rate measuring device to measure the corrosion rate of metal components is as follows:

[002...

Embodiment 2

[0044] An embodiment of the present invention provides a corrosion rate measurement method, using the corrosion rate measurement device in Embodiment 1 of the present invention for corrosion rate measurement, the corrosion rate measurement method includes:

[0045] Step S1, measure the magnitude of all the currents generated between the substrate and the metal layer with an ammeter.

[0046] Step S2. According to the current data and the material of the substrate, the corrosion rate of the substrate during the test period is obtained. The current data includes the magnitude of all currents and the duration of each current measured by the ammeter.

[0047] Exemplarily, according to the current data and the material of the substrate, the specific steps of obtaining the corrosion rate of the substrate during the test cycle include:

[0048] According to the magnitude of all currents and the duration of each current, the number Q of electrons transferred between the substrate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com