Soft magnetic steel and method for manufacturing same, and soft magnetic component obtained from soft magnetic steel

A manufacturing method and soft magnetic technology, applied to magnetic materials, electrical components, manufacturing tools, etc., can solve the problems of deterioration of productivity and high alloy cost, and achieve the effects of suppressing magnetic aging, excellent cold forgeability, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Hereinafter, the present invention will be described more specifically with reference to examples. The present invention is not limited by the following examples, and within the range that can meet the above-mentioned and hereinafter-described purposes, of course, it can also be appropriately modified and implemented, and all of these are included in the technical scope of the present invention.

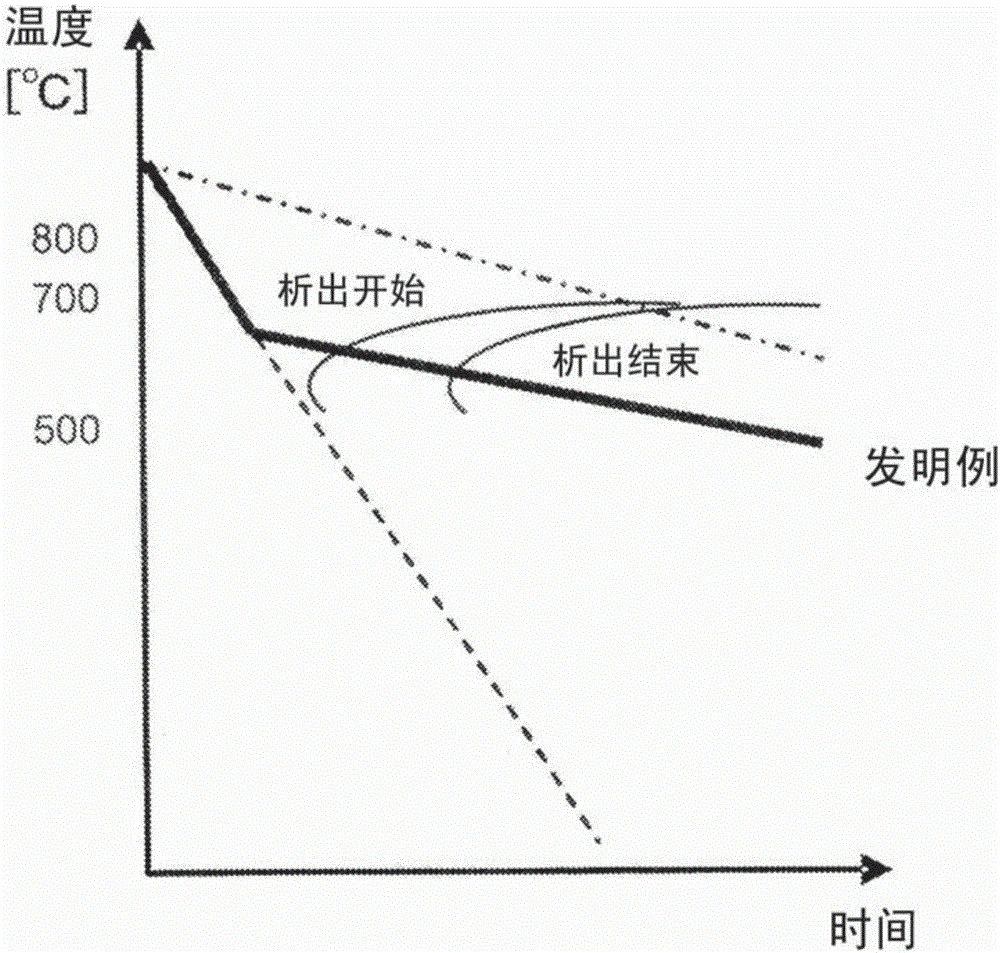

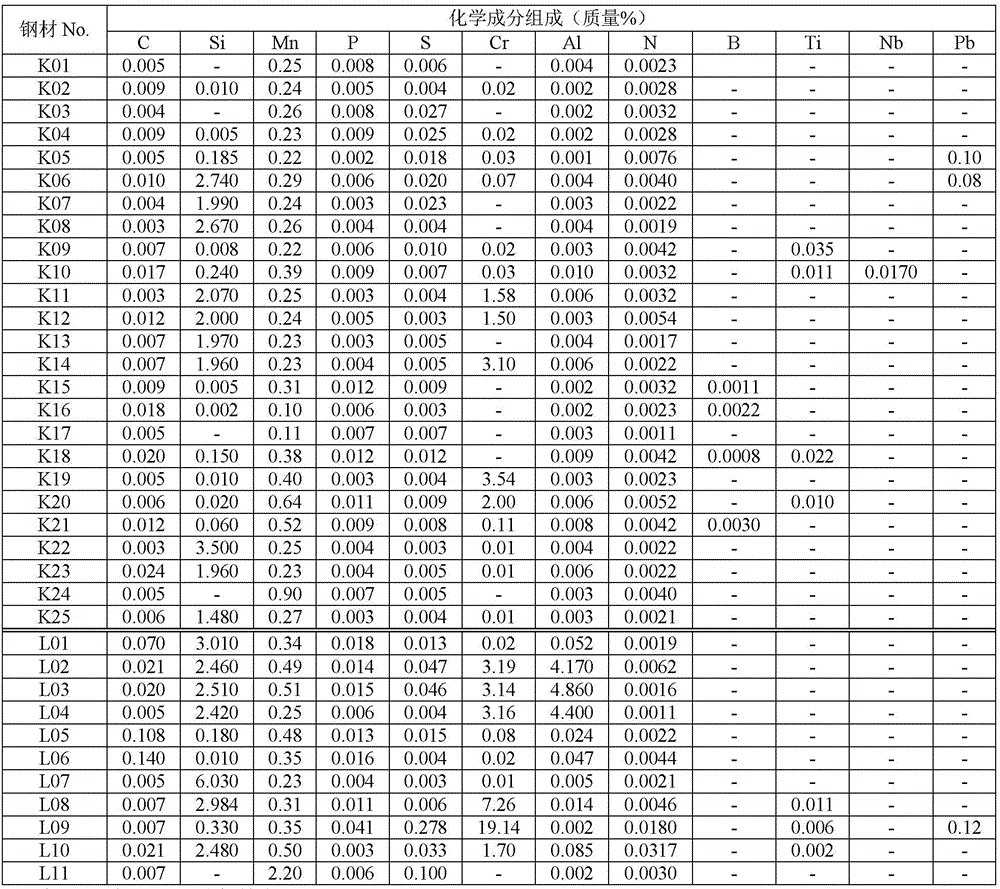

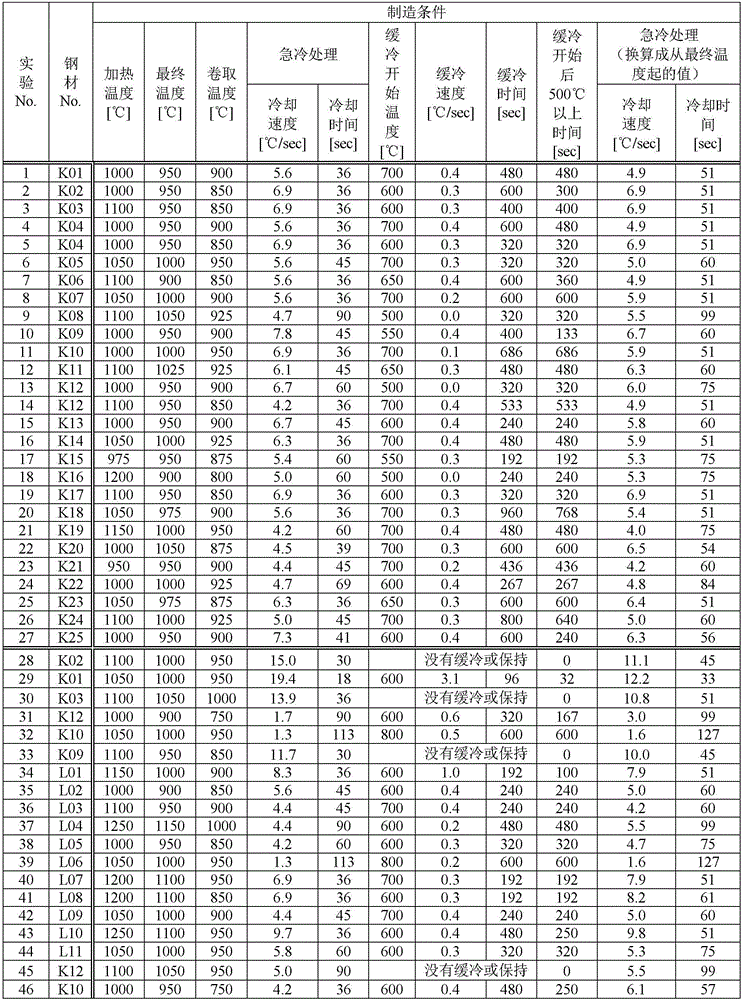

[0106] Following the usual melting method, the steel with the composition shown in Table 1 was smelted and cast, and then hot rolled and cooled under the conditions shown in Table 2 to obtain a steel material with a diameter of 20 mm, that is, a rolled material. That is, hot rolling was performed at the heating temperature and final temperature described in Table 2, and after the coiling was completed at the coiling temperature described in Table 2, rapid cooling and slow cooling were performed under the conditions described in Table 2. In addition, the balance of the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap