Tea leaf stir-frying machine

A stir-frying machine and tea technology, which is applied in the field of daily operation equipment and tea stir-frying machines, can solve the problems of small and medium-sized enterprises, such as limited application range, uneven heating, etc., and achieve multiple functions, reduce production costs and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

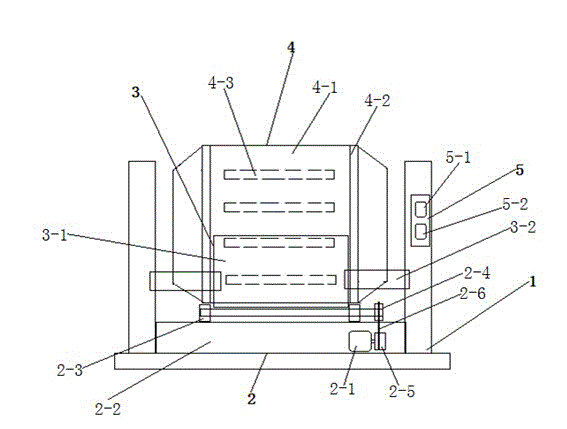

[0023] Such as figure 1 Shown:

[0024] The present invention provides a tea stir-frying machine, comprising a frame 1, a set of bearing units 2 arranged at intervals is installed on the frame 1, and a heating unit 3 is installed between the bearing units 2; the bearing unit 2 The upper rack is provided with a stir-frying unit 4; the load-bearing unit 2 and the heating unit 3 are connected to the control unit 5 respectively.

[0025] The optimal load-bearing unit, heating unit, and control unit of this scheme are organically combined so that the stir-frying machine has fast heating, uniform heating, simple operation, and effectively solves the problem of high labor intensity, improves production efficiency, and reduces The production cost, the overall structure is simple and practical, the cost is low, and it can be widely used in agricultural companies and tea workshops.

Embodiment 2

[0027] Such as figure 1 Shown:

[0028] On the basis of embodiment 1, a tea stir-frying machine as described in the above technical solution, the load-bearing unit 2 includes a base 2-2 with a built-in motor 2-1, and the upper part of the base 2-2 is spaced apart There is a set of coaxial hobbing 2-3, the shaft end of the hobbing 2-3 is equipped with a positive pulley 2-4; the rotating shaft of the motor 2-1 is equipped with a secondary pulley 2-5; the positive pulley 2 -4 and auxiliary pulley 2-5 are driven by belt 2-6.

[0029] The preferred base of this solution is provided with coaxial hobbing gears at the front and back through the shaft end pulley and connected with the motor, which reduces the use of the motor, reduces the cost of the whole machine, has stable transmission, convenient installation and maintenance, simple structure and strong practicability.

[0030] As in the tea stir-frying machine described in the above technical solution, the stir-frying unit 4 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com