An automatic positive molding machine

A positive mold machine, automatic technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of difficulty in the mold opening process of automatic production lines, and achieve the effect of wide application and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

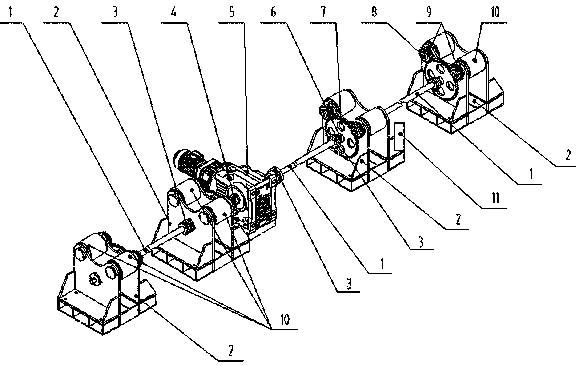

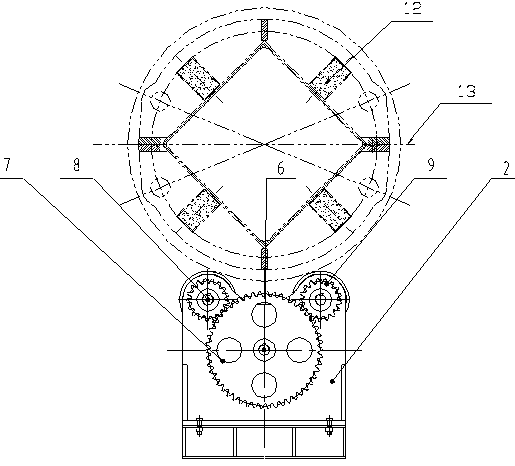

[0011] Such as figure 1 As shown, an automatic positive mold machine is characterized in that it includes four fixed bracket parts, a connecting shaft 1, a position sensor 11 and a gear motor 5, each fixed bracket part is connected by a connecting shaft 1, and the position sensor 11 is fixed on the second On the three fixed supports, the position of the pipe mold 12 can be sensed and the geared motor 5 can be controlled to rotate. The fixed support components include the fixed support 2, the central rotating shaft 6, the large gear 7, the pinion shaft 8, the pinion 9 and the support Cylinder 10, three shafts are installed on each fixed support 2, wherein a center shaft 6, two pinion shafts 8, on the center shaft 6 a large gear 7 is installed and rotates with the center shaft 6, on the pinion shaft The pinion 9 and the support roller 10 are installed on the 8 and rotate with the pinion shaft 8. The large gear 7 and the two pinions 9 mesh with each other, thereby transmitting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com