Intelligent blotting-up prevention printing system

A printing system and anti-suction technology, applied in printing and other directions, can solve problems such as clogged or damaged nozzles, damaged printing nozzles, and poor image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will now be described with reference to the drawings.

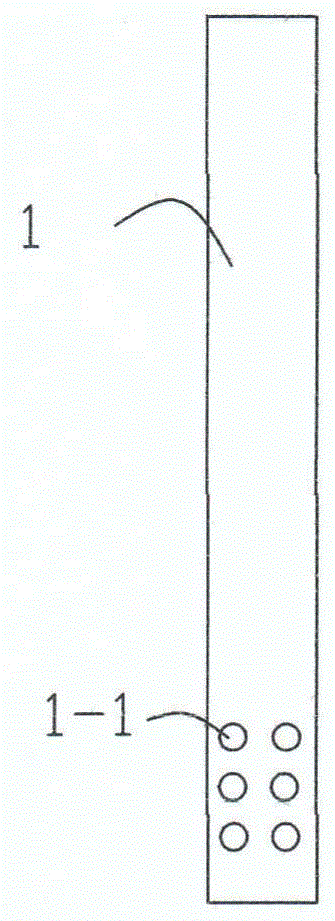

[0013] figure 1 It is a schematic diagram of the first preferred embodiment of the ink introduction device of the present invention. Such as figure 1 As shown, one end of the ink guiding device 1 is provided with a limiting mechanism 1-1.

[0014] Such as figure 1 As shown, the limit mechanism is composed of a number of small holes 1-1. In this way, when the ink level drops to be flush with the small hole 1-1 at the upper end, the pressure inside and outside the ink drawing device is balanced, and the ink drawing device 1 can no longer absorb ink, thereby ensuring that the ink will not be sucked dry.

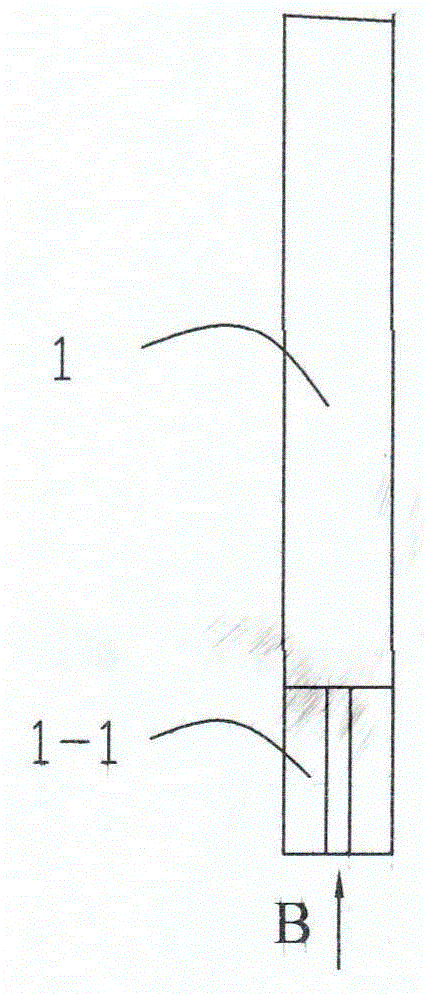

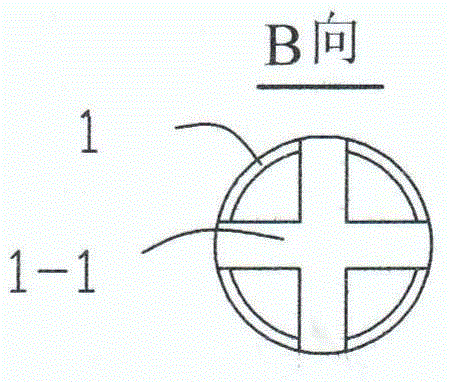

[0015] figure 2 with image 3 It is a schematic diagram of the third preferred embodiment of the ink introduction device of the present invention. This embodiment provides a limit mechanism with another structure. Such as figure 2 with image 3 As shown, the limit mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com