A knife shim mechanism and binding machine

A binding machine and knife shim technology, applied in binding and other directions, can solve problems that cannot meet the direction of automation development, and achieve the effect of simple structure and precise linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

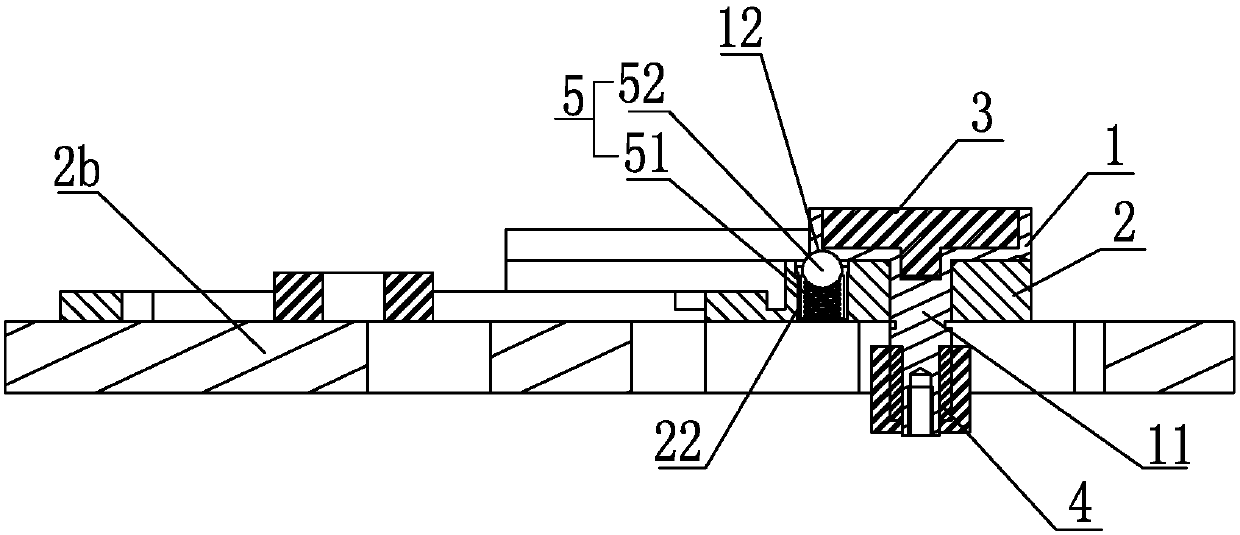

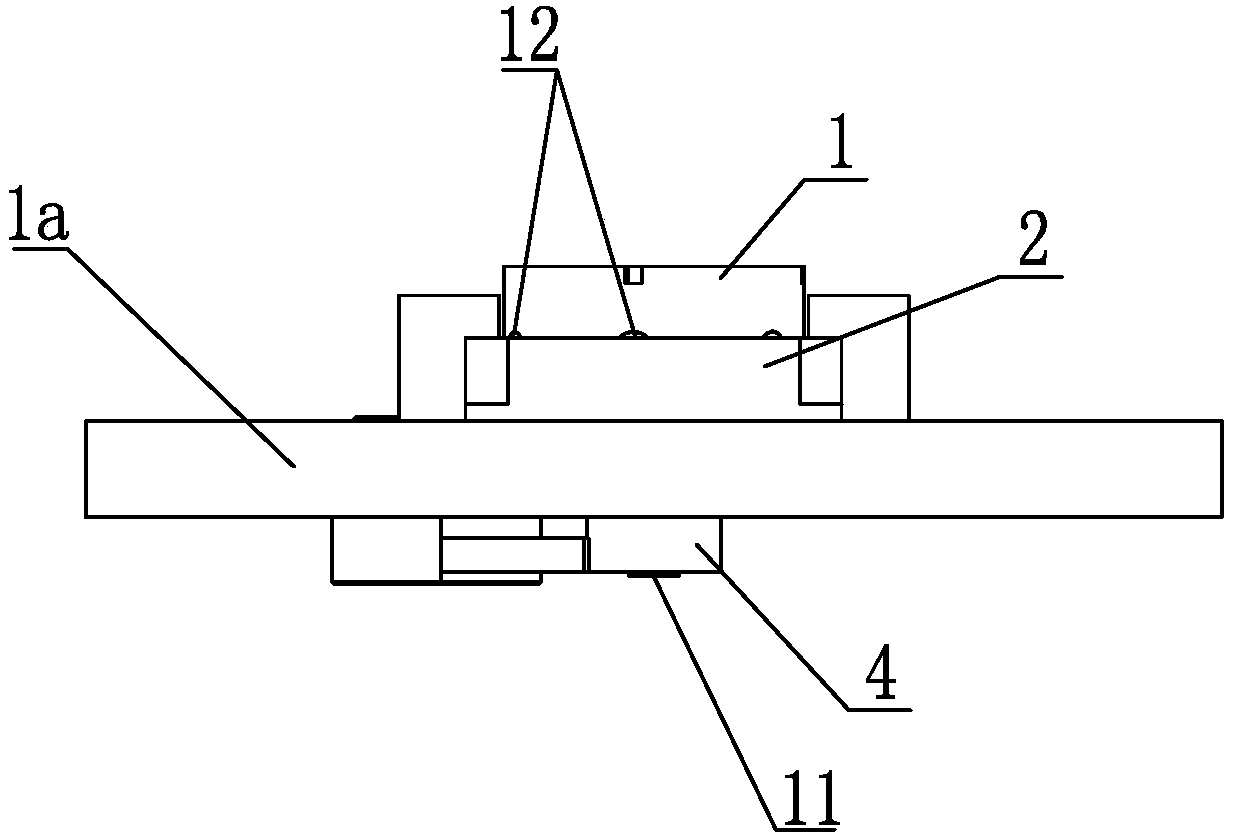

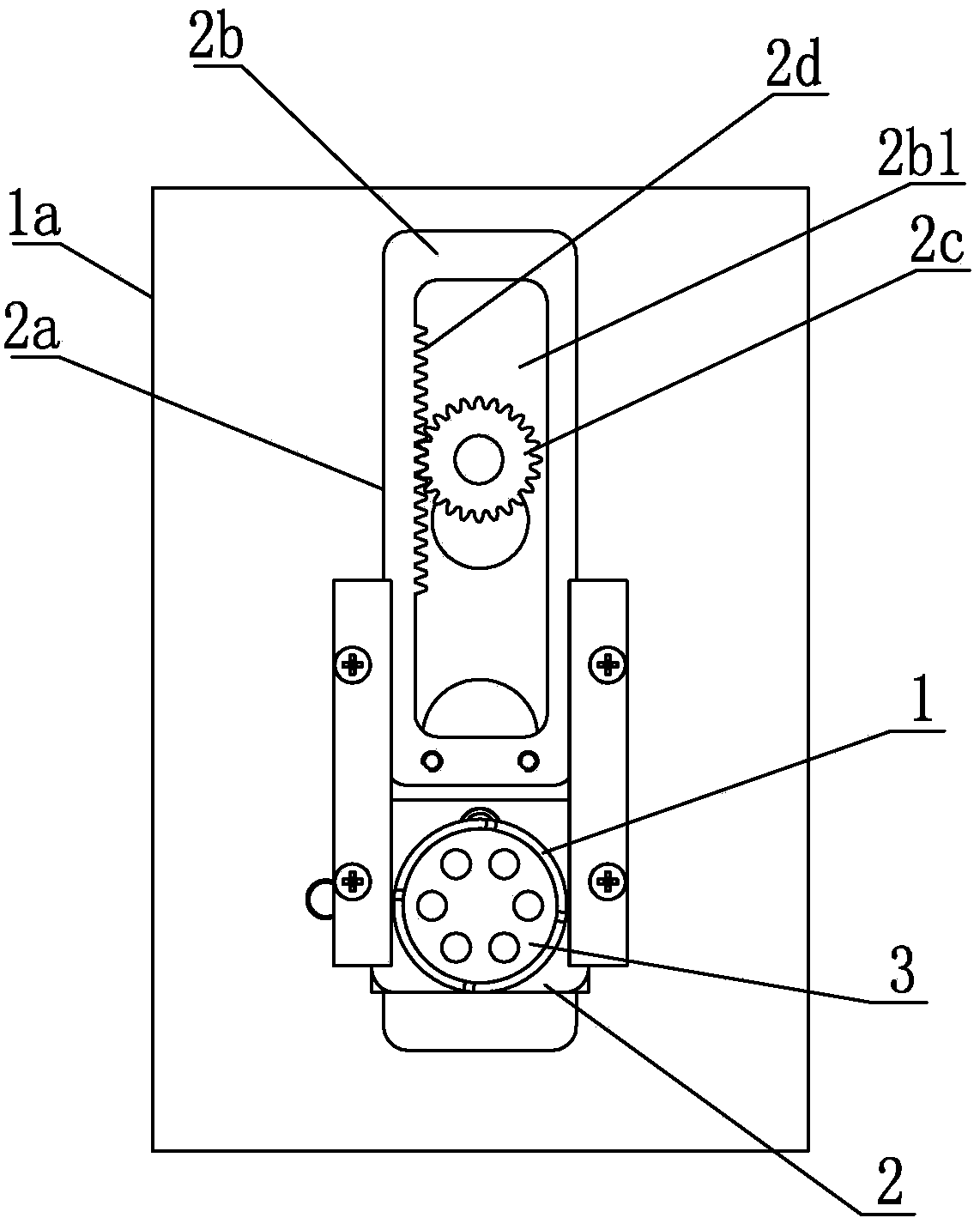

[0047] Such as figure 1 and Figure 25 As shown, a knife shim mechanism includes a rotatable knife shim device a, which is rotatably positioned on the positioning seat 2, and the rotatable knife shim device a is provided with a one-way bearing 4.

[0048] One-way bearing 4 is provided with driving lever 6 or rotating gear 9 that drives it to rotate.

[0049] It also includes a toggle device b positioned correspondingly to the toggle one-way bearing 4, and a clutch device c for clutch switching is provided between the toggle device b and the rotary knife shim device a.

[0050] The rotatable knife shim device a is provided with a centering shaft 11, which is rotatably positioned on the positioning seat 2 through the centering shaft 11, and the one-way bearing 4 is sleeved on the rotatable seat 1 or the centering shaft 11, and the one-way bearing 4 is A rotating gear 9 is provided.

[0051] The rotatable knife shim device a is provided with a centering shaft 11, which is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com