Interlocking binding machine drilling device and binding machine

A drilling device and binding machine technology, applied in binding, metal processing, etc., can solve problems such as poor rotation stability, increased external dimensions, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

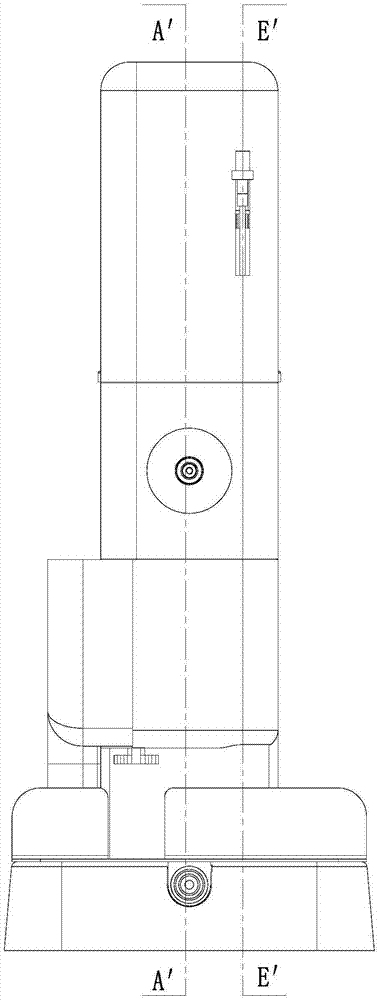

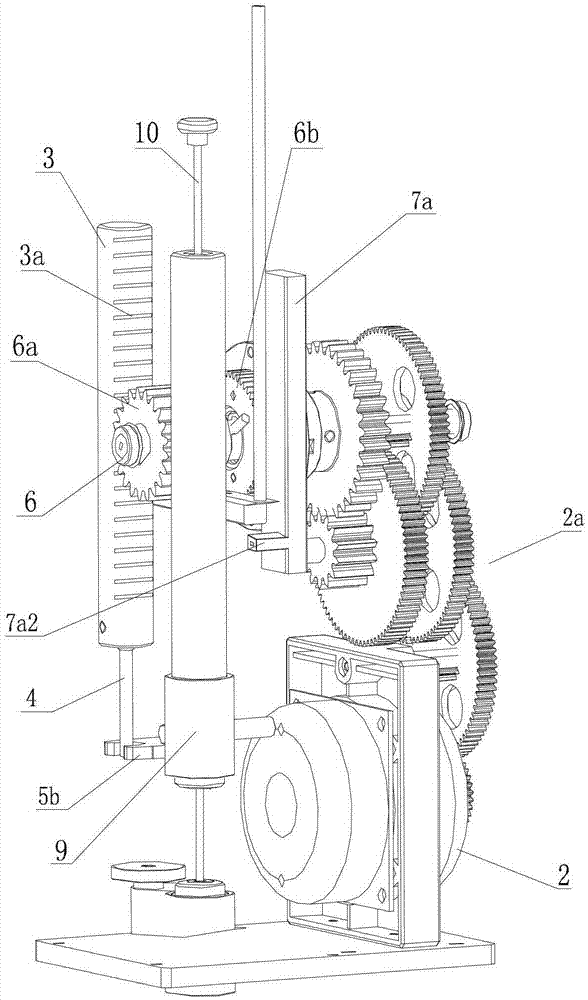

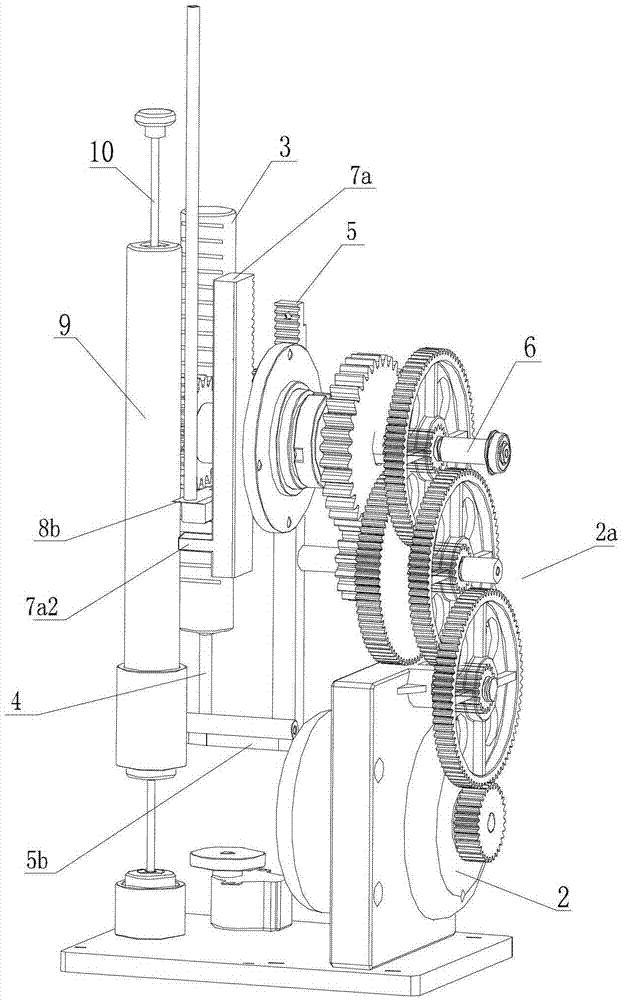

[0059] Such as Figure 1 to Figure 37 As shown, a drilling device for an interlocking binding machine includes a first motor 2 on a fixed machine base 1, a horizontal rotating shaft 6, a drilling guide post 3, a paper pressing guide post 5, and a drill is arranged at the lower end of the drilling guide post 3. Knife 4, platen platen 5b is set at the lower end of platen guide post 5, first motor 2 is provided with reduction gear set and is connected with horizontally arranged horizontal rotating shaft 6, and horizontal rotating shaft 6 is provided with first driving gear 6a and second driving gear 6b, horizontal The rotating shaft 6 is fixedly connected with the first driving gear 6a, and a torsion spring 7 is arranged between the horizontal rotating shaft 6 and the second driving gear 6b to be rotatably connected. The side and the side wall are provided with guide teeth 3a, 5a respectively engaged with the first driving gear 6a and the second driving gear 6b.

[0060] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com