A-shaped storage bracket

An A-shaped and font-shaped technology is applied in the field of glass transfer brackets, which can solve problems such as affecting the appearance of glass, wear and tear of glass surface ties, and easy sliding, and achieve the effect of preventing wear and ensuring beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

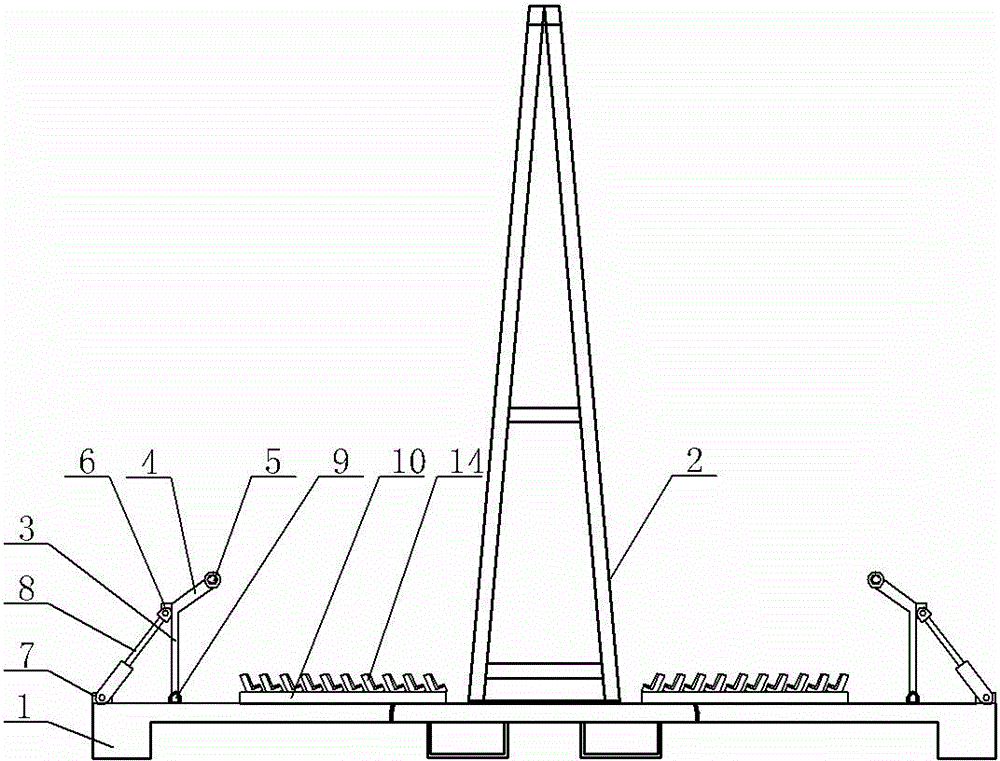

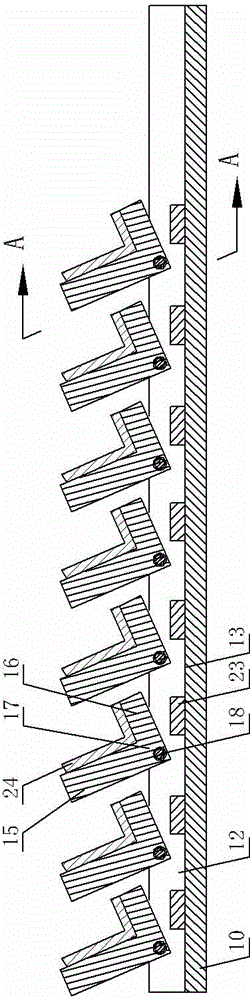

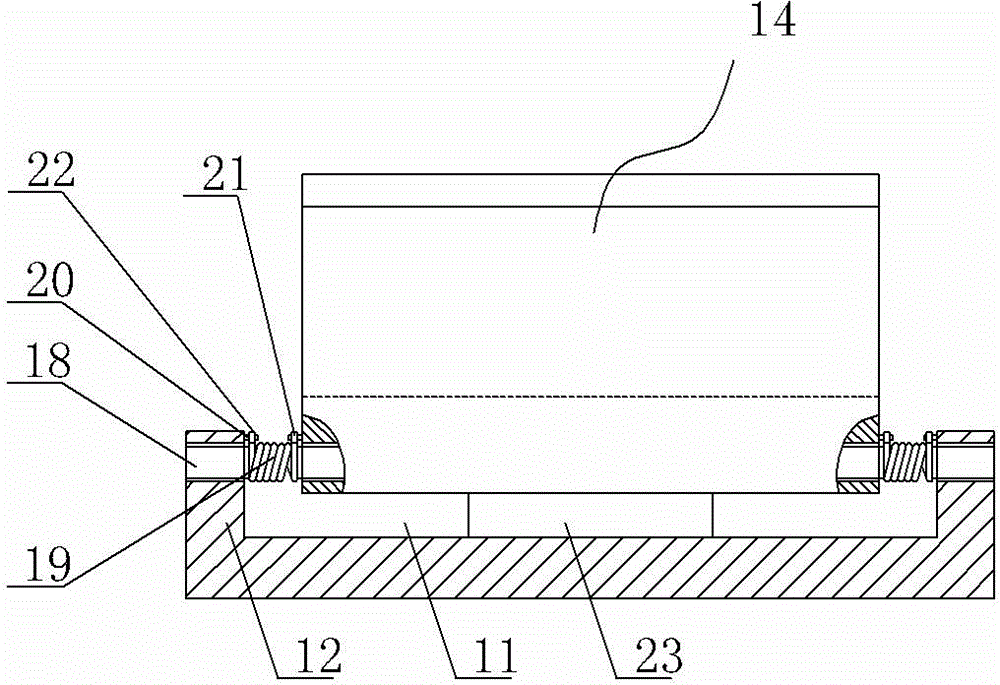

[0014] Such as Figure 1 to Figure 3 As shown, it includes a bottom frame 1 and an A-shaped support 2 fixed on the top of the bottom frame 1, and is located on both sides of the A-shaped support 2. A pair of pillow bars 10 are respectively arranged on the bottom frame 1, and the upper middle position of the pillow bars 10 is provided with U-shaped slot 11 arranged along the length direction, U-shaped slot 11 is provided with a number of L-shaped clamps 14, L-shaped clamps 14 include an upper clamp 15 and a lower clamp 16 vertically fixed on the lower end of the upper clamp 15, supporting The shaft 18 is supported on the two side walls 12 of the U-shaped groove 11 after passing through the connecting portion 17 where the upper clamping plate 15 and the lower clamping plate 16 intersect, between the connecting portion 17 and the two side walls 12 of the U-shaped groove 11, the supporting shaft 18 The upper cover is provided with a torsion spring 19, and the two spring legs 21, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com