Water removing and blow-dry structure for agricultural product processing

A technology for agricultural product processing and agricultural products, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large installation site cost, inability to perform and participate in specific steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

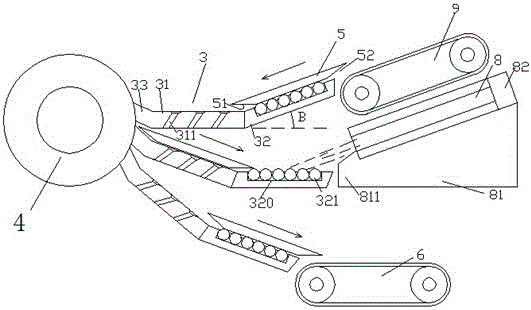

[0008] Combine below Figure 1-2 The present invention will be described in detail.

[0009] According to the embodiment of the present invention, the draining and drying structure for agricultural product processing includes a rotating main shaft 4, and three station conversion arms 3 are fixedly arranged on the outer circumference of the rotating main shaft 4, and are equally spaced in the angular direction. Each station switching arm 3 all includes a draining section 31 close to the rotating main shaft 4 and a transition blowing section 32 connected to the outer end of the draining section 31, and the transition blowing section 32 is connected to the draining section 31. The sections 31 form an acute angle B, and the drain section 31 is provided with a plurality of drain holes 311 inclined from bottom to top to the outer end, and the transition blow section 32 is provided with holes parallel to the transition section. 32 of the ball groove 320, the ball groove 320 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com