A cigarette product with good sensory comfort

A technology for comfort and cigarettes, which is applied in the fields of tobacco, fat generation, and tobacco treatment, etc. It can solve the problems of not being able to restore the aroma of tobacco leaves, the taste of reconstituted tobacco leaves, and the lack of taste, so as to enhance the sense of body fluid in smoke and improve the quality of cigarettes. Comfort, the effect of improving sensory comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

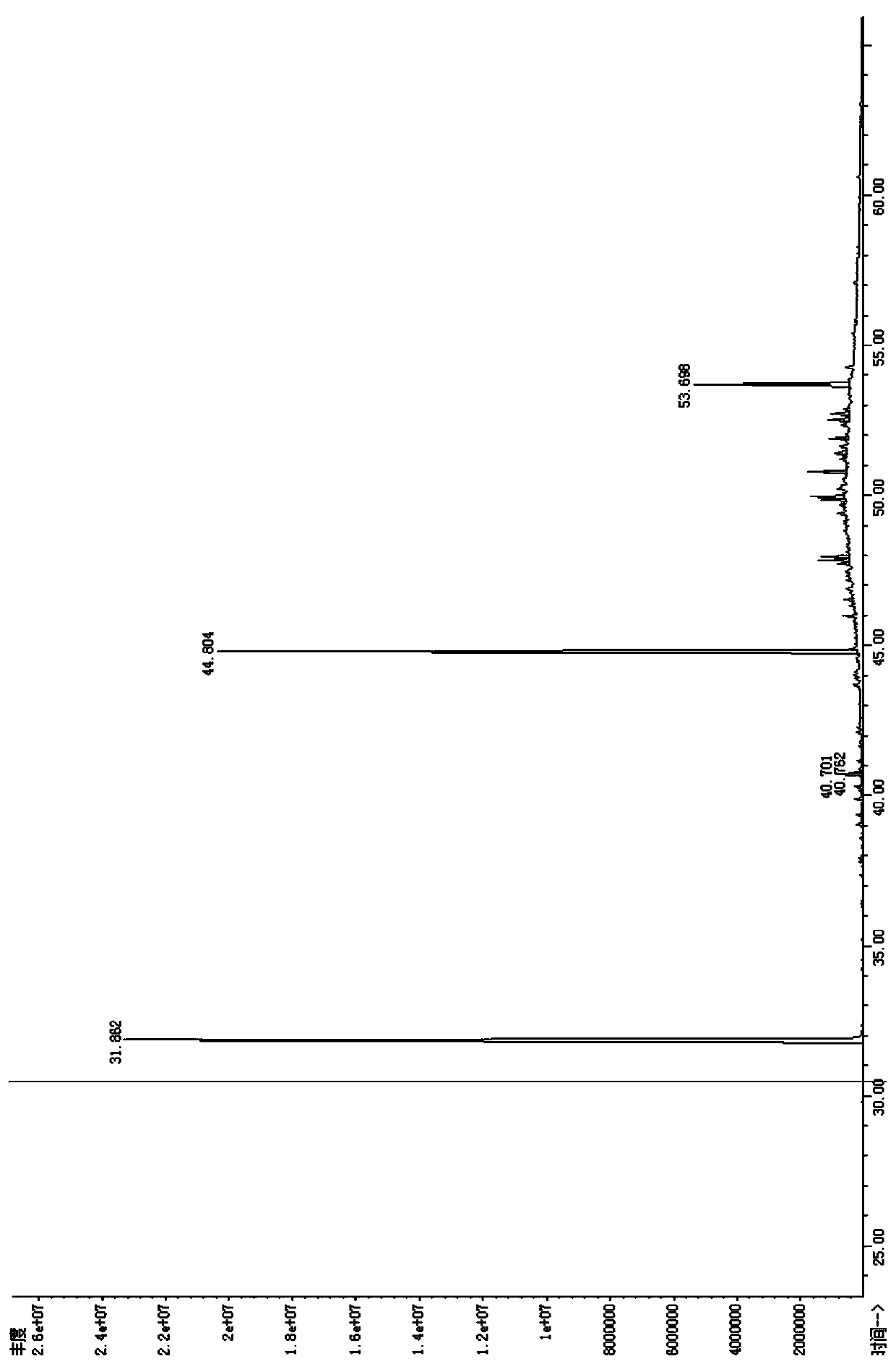

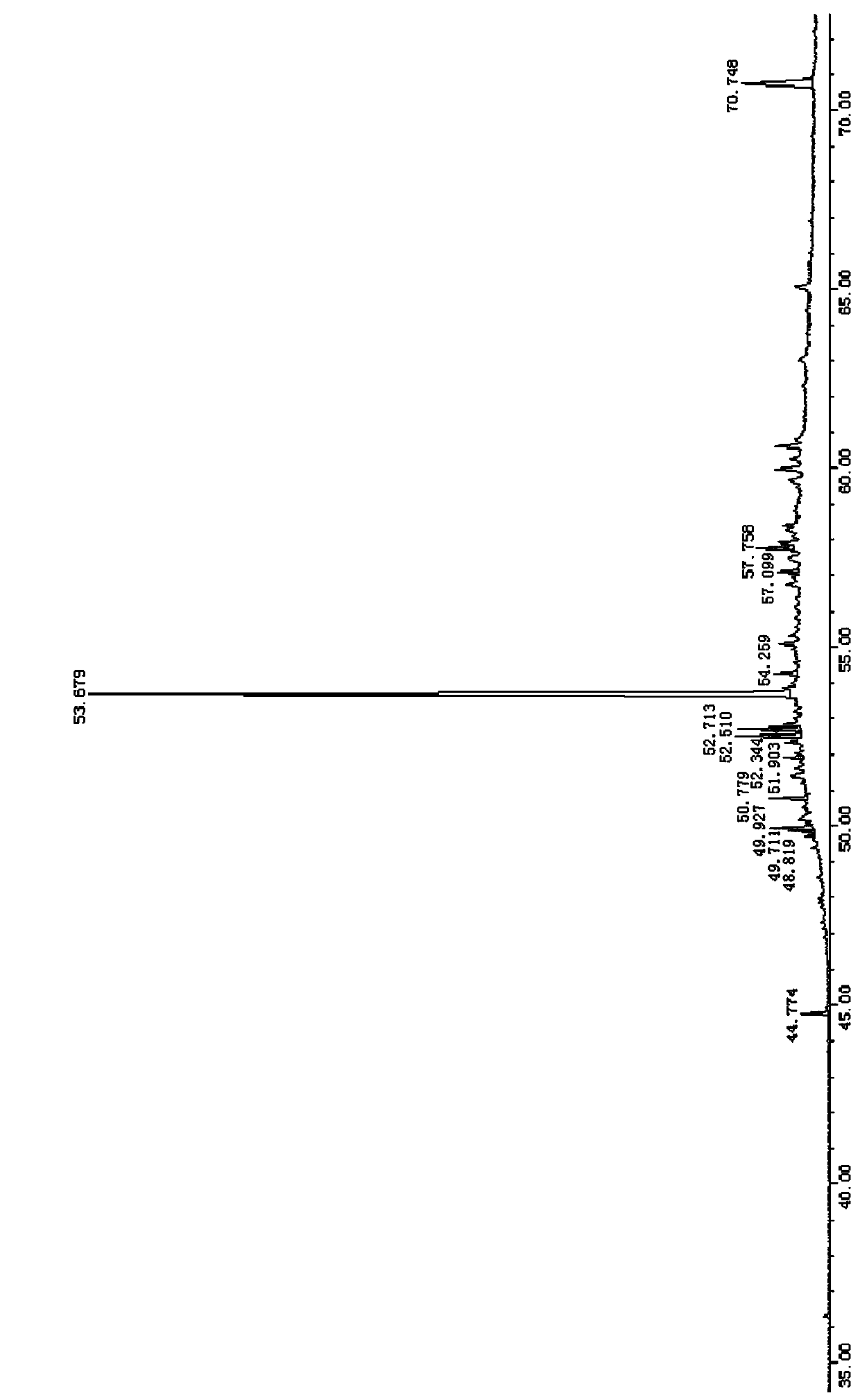

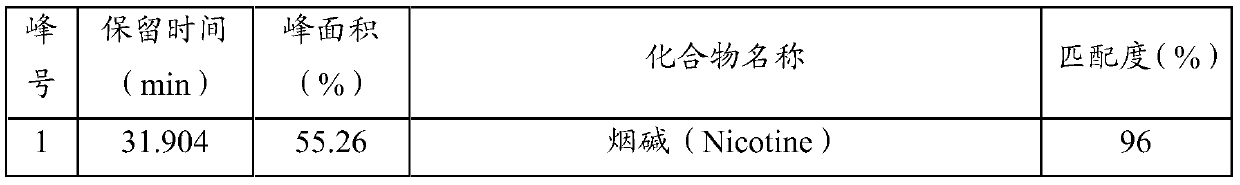

[0041] After crushing 8kg of tobacco raw material to 60 mesh, put it into the extraction kettle, the extraction pressure is 20MPa, the extraction temperature is 35°C, and the supercritical CO 2 The flow rate is 80kg / h, supercritical CO 2 The volume fraction of the entrainer propylene glycol is 5%, and the extraction time is 2 hours.

[0042] The extraction product enters the two-stage separation tank I and the separation tank II successively for two-stage separation. The pressure of the separation tank I is 5 MPa, the temperature of the separation tank I is 35 ° C, the pressure of the separation tank II is 4 MPa, and the temperature of the separation tank II is 35 ° C. 1050g of yellow mixed extract containing aroma substances.

[0043] Heat 1050 grams of yellow mixed extract to 60°C for melting, then carry out two stages of molecular distillation successively, the equipment pressure of the first stage molecular distillation is 200Pa, and the heating temperature of the first s...

Embodiment 2

[0047] After crushing 10kg of tobacco raw material to 80 mesh, put it into the extraction kettle, the extraction pressure is 25MPa, the extraction temperature is 40°C, and the supercritical CO 2 The flow rate is 120kg / h, supercritical CO 2 The volume fraction of the entrainer propylene glycol is 10%, and the extraction time is 3 hours.

[0048] The extraction product enters the two-stage separation tank I and the separation tank II successively for two-stage separation. The pressure of the separation tank I is 8 MPa, the temperature of the separation tank I is 40 ° C, the pressure of the separation tank II is 4 MPa, and the temperature of the separation tank II is 40 ° C. 1820 grams of yellow mixed extract containing aroma substances.

[0049] Heat 1820g of the yellow mixed extract to 60°C to melt, then carry out two stages of molecular distillation in sequence, the equipment pressure of the first stage molecular distillation is 400Pa, the heating temperature of the first sta...

Embodiment 3

[0053] After crushing 9kg of tobacco raw material to 80 mesh, put it into the extraction kettle, the extraction pressure is 25MPa, the extraction temperature is 40°C, and the supercritical CO 2 The flow rate is 120kg / h, supercritical CO 2 The volume fraction of the entrainer propylene glycol is 10%, and the extraction time is 3 hours.

[0054] The extraction product enters the two-stage separation tank I and the separation tank II successively for two-stage separation. The pressure of the separation tank I is 8 MPa, the temperature of the separation tank I is 40 ° C, the pressure of the separation tank II is 4 MPa, and the temperature of the separation tank II is 40 ° C. 1910g yellow mixed extract containing aromatizing substances.

[0055] Heat 1910g of yellow mixed extract to 60°C to melt, then carry out three-stage molecular distillation in sequence, the equipment pressure of the first-stage molecular distillation is 400Pa, the temperature of the first-stage molecular dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com