Full grouting sleeve and grouting method for prefabricated building steel bar connection

A technology for grouting sleeves and building steel bars, which is applied to buildings, building components, building reinforcements, etc., can solve problems such as restricting prefabricated frame structures, and achieve the effects of improving construction efficiency, making the construction process simple and easy, and improving link efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

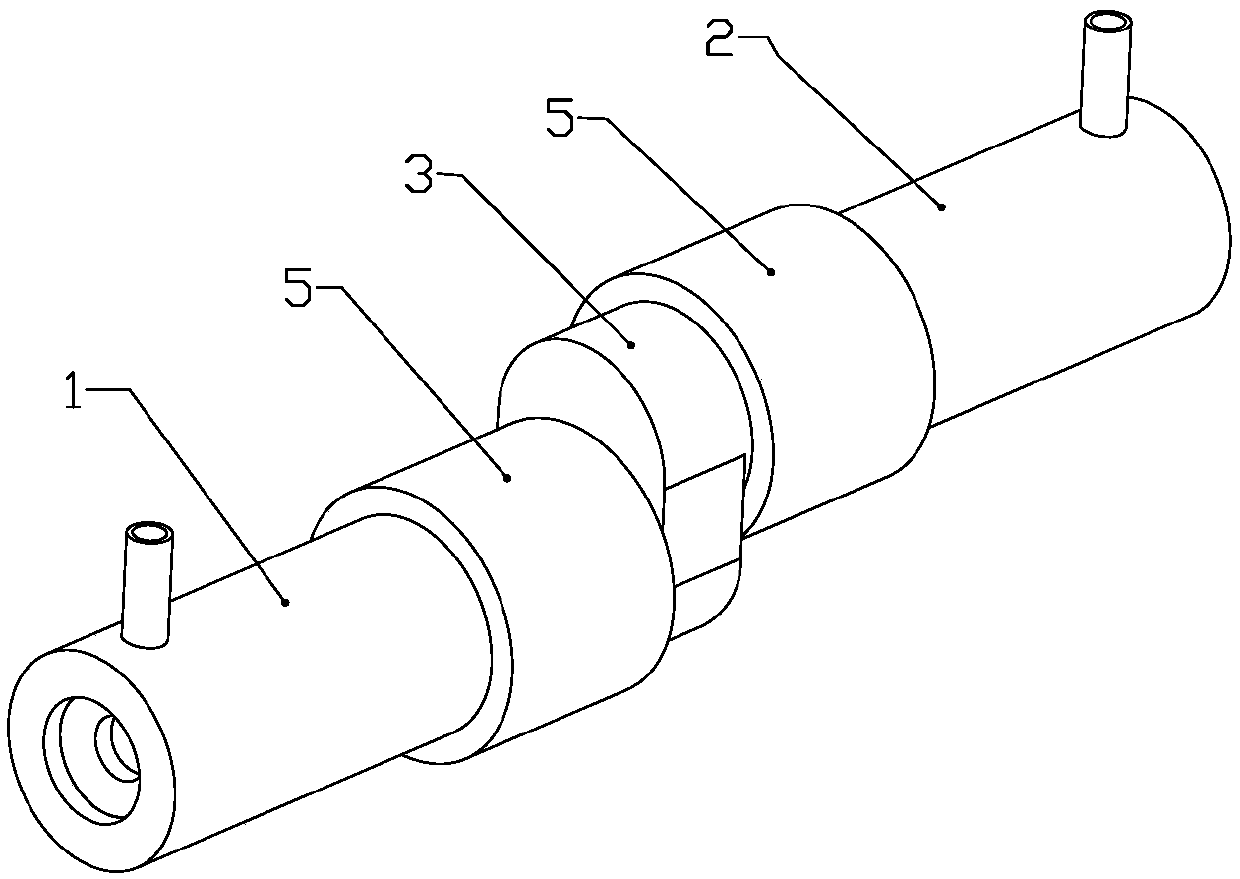

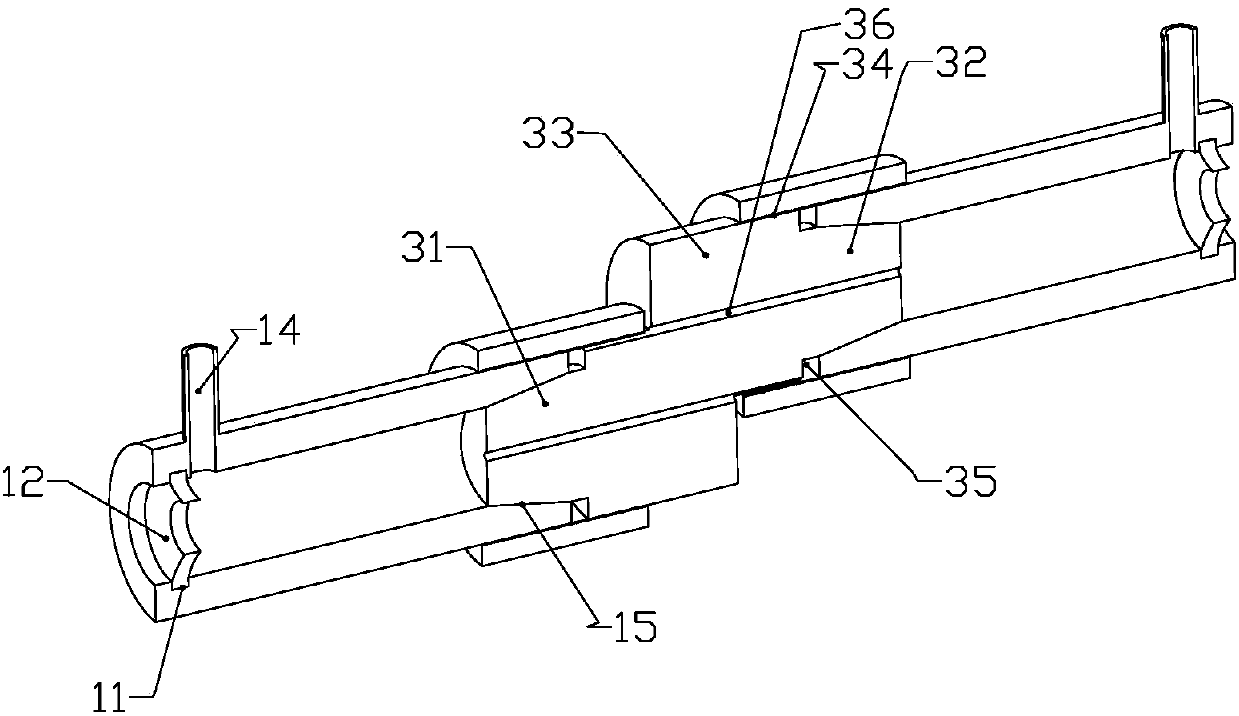

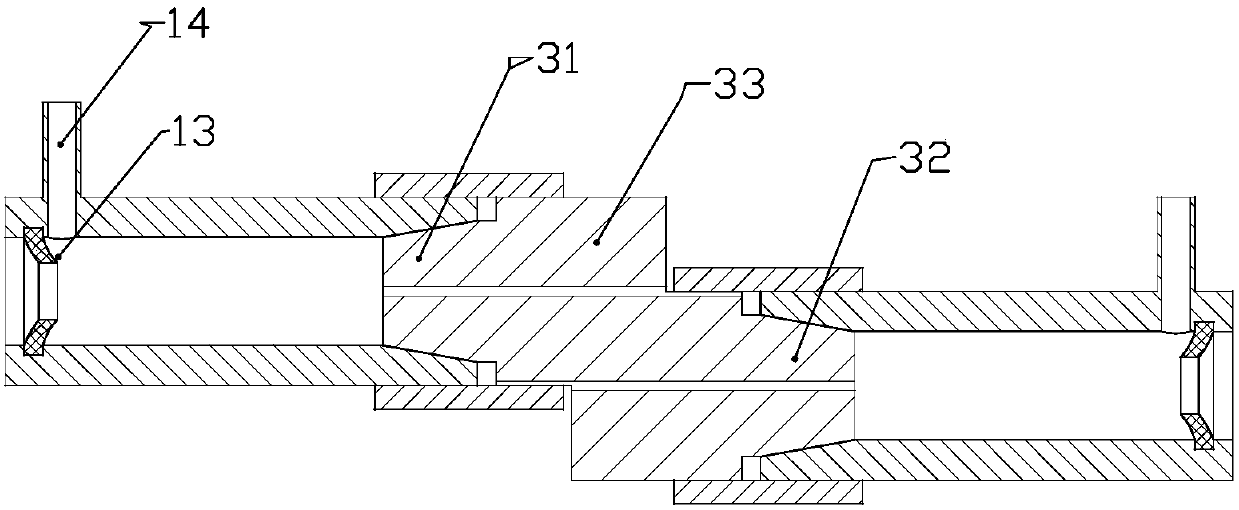

[0036] Such as Figure 1 to Figure 7 As shown, the full grouting sleeve for steel bar connection in this embodiment includes a first grouting sleeve 1 and a second grouting sleeve 2 on both sides, and an eccentric joint 3 connecting the two grouting sleeves, wherein the first grouting sleeve The first grouting sleeve 1 and the second grouting sleeve 2 are respectively provided with grouting holes, and the two sections of the grouting sleeves are connected through the eccentric joint 3, and the dislocated core-through steel bars are connected through the eccentric joint.

[0037] specifically,

[0038] The structure of the first grouting sleeve 1 is as follows, refer to figure 2 , a seamless steel pipe with a diameter of 20 cm is used for turning processing, and the length is more than 10 times the diameter, that is, 20 cm. An annular groove 11 is used to place the first sealing card 12. The first sealing card is a steel sheet with a thickness of about 1 mm, which is a stamp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap