A clutch-type crawler transmission mechanism and a tower-type three-dimensional garage based on the mechanism

A transmission mechanism and clutch-type technology, which is applied in the field of tower-type three-dimensional garages, can solve problems such as high driving technical requirements and unstable movement, and achieve the effects of high operating efficiency, no safety hazards, and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

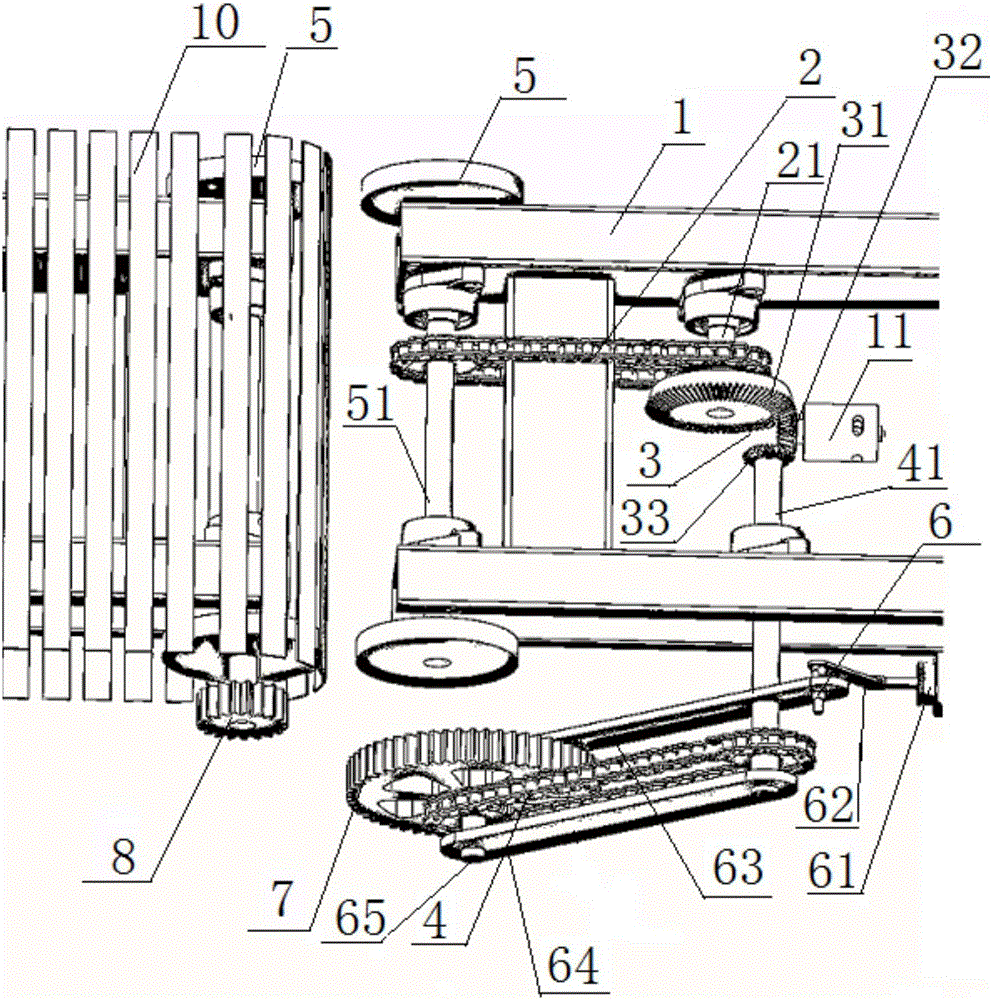

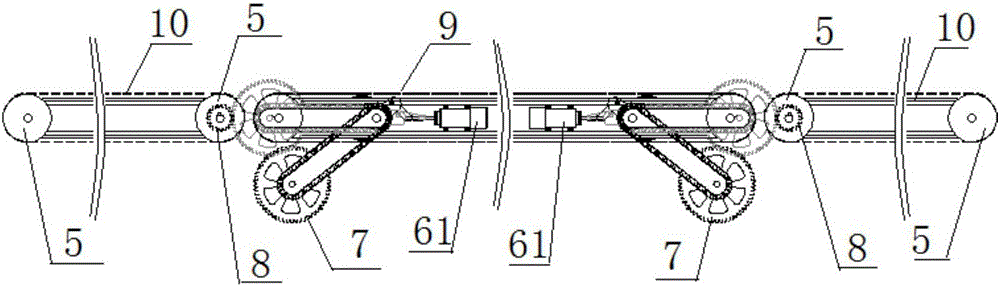

[0041] A clutch type crawler transmission mechanism in this embodiment includes a main belt 9, an auxiliary belt 10 and a motor A11, and also includes a sprocket-chain mechanism and a bevel gear set 3, wherein: as figure 2 As shown, the main belt 9 and the auxiliary belt 10 are tops and are arranged horizontally, and there is a gap between the two, which is smaller than the radius of the car wheel; the bevel gear set 3 is connected to the rotating shaft of the motor A11; the sprocket-chain mechanism is 2 are connected through the bevel gear set 3 transmission, one of which drives the main belt 9 to rotate; the other drives the auxiliary belt 10 to rotate.

[0042] In the clutch-type crawler transmission mechanism of this embodiment, the car is driven to the surface of the main belt 9, left standing, and the motor A11 is started. Driven by the motor A11, the two sprocket-chain mechanisms are driven by the bevel gear set 3. One of the sprocket-chain mechanisms drives the main b...

Embodiment 2

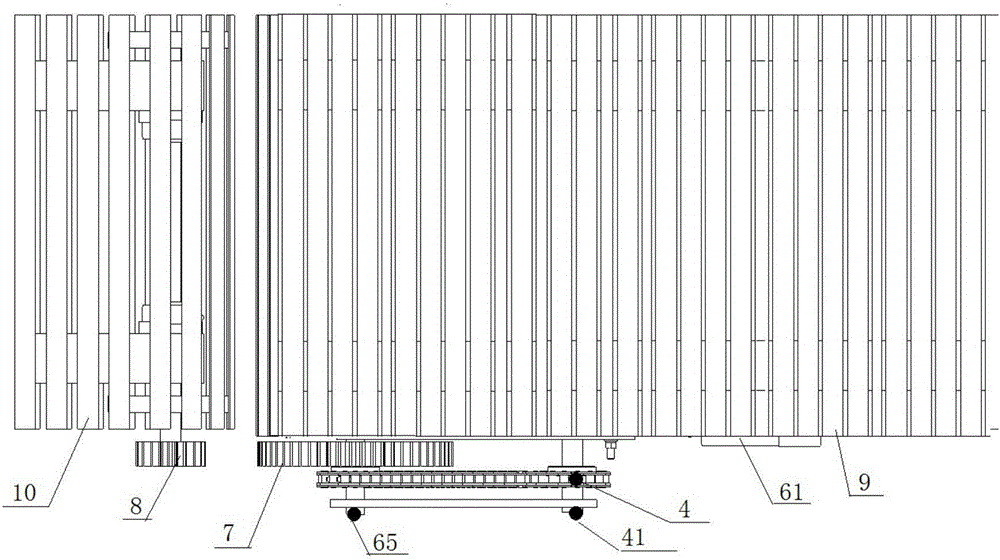

[0045] A kind of clutch type crawler conveying mechanism of the present embodiment and the tower type three-dimensional garage based on this mechanism, the basic structure is the same as embodiment 1, and the improvements are as follows: figure 1 As shown, it also includes a gear A7 and a gear B8; the two sprocket-chain mechanisms are respectively a sprocket-chain mechanism A2 and a sprocket-chain mechanism B4, which are respectively arranged in the inner space of the main belt 9 and on the side of the main belt 9; The sprocket-chain mechanism A2 drives the rotation of the main belt 9; the sprocket-chain mechanism B4 drives the rotation of the secondary belt 10 by driving the gear A7 and gear B8 which are meshed and connected; It is connected with the crawler wheel 5 of the secondary belt 10 in transmission. Gear set 3 includes bevel gear A31, bevel gear B32 and bevel gear C33. The two sides of bevel gear B32 are externally meshed with bevel gear A31 and bevel gear C33 respect...

Embodiment 3

[0052] A kind of clutch type crawler conveyor mechanism of the present embodiment and based on this mechanism, the basic structure is the same as embodiment 2, and the improvement is: it also includes a clutch mechanism 6 arranged between the main belt 9 and the sprocket-chain mechanism B4; the clutch Mechanism 6 comprises telescopic device 61, swing plate 62, clutch plate A63, clutch plate B64 and linkage rod 65, and telescopic device 61 is fixed on the outside of the vertical frame of well shape frame 1 of main band 9, and the end of the telescopic rod of telescopic device 61 One end of head and clutch plate A63 is hinged with the two ends of swing plate 62 respectively, and clutch plate A63 is hinged on the drive shaft C41 again, and the other end of clutch plate A63 is fixedly connected with an end of linkage lever 65, and the other end of linkage lever 65 and One end of the clutch plate B64 is fixedly connected, and the other end of the clutch plate B64 is hinged to the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com