A mechanical speed detection and tracking adjustment device

A speed detection and adjustment device technology, applied in the field of speed feedback and tracking adjustment devices, mechanical speed detection and tracking adjustment devices, can solve the problems that the speed sensor is susceptible to vibration shock, oil, dust and impurities, etc., to achieve Small footprint, stable performance and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

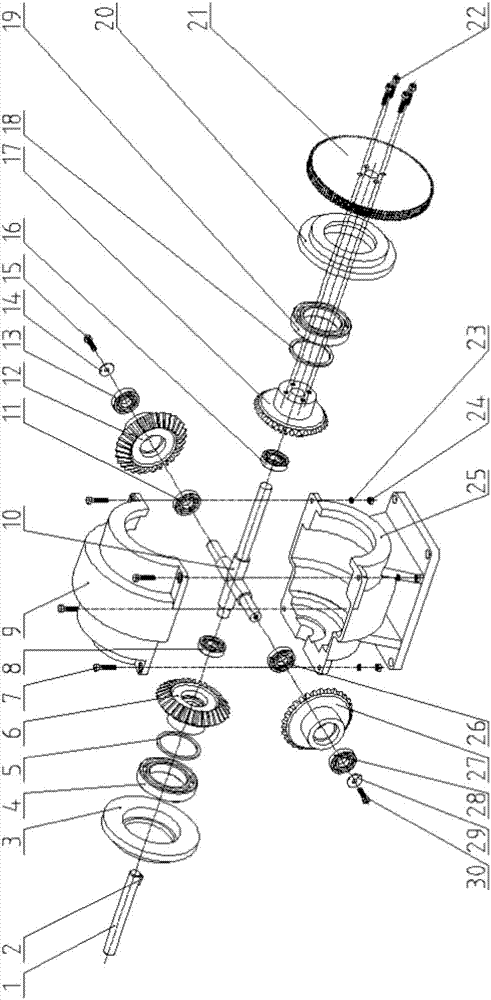

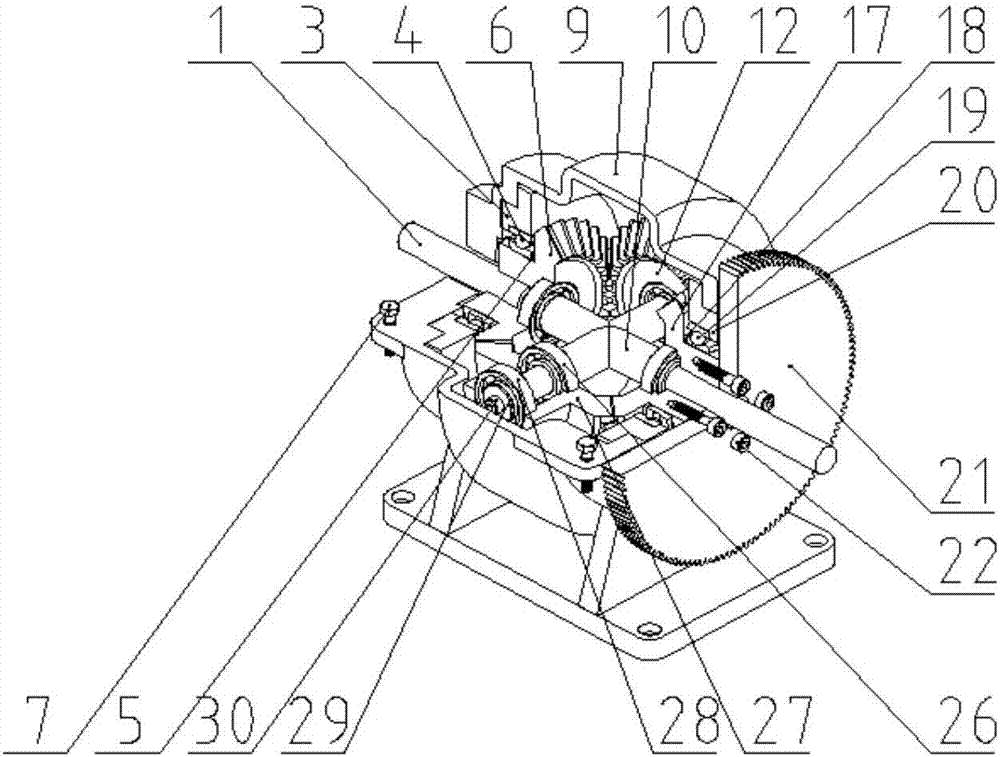

[0023] control figure 1 , figure 2 and image 3 As shown, the mechanical speed detection and tracking adjustment device of the present invention includes a base 25, an upper cover 9, a cross shaft 10, a first bevel gear 6, a second bevel gear 12, a third bevel gear 17, a fourth bevel The gear 27, the cylindrical gear 21 and the input shaft 1, the upper cover 9 are fixedly connected with the base 25 through the hex head bolt group 7, the spring washer group 23 and the hex nut group 24 to form a box structure, and the cross shaft 10 is installed in the box, and the cross shaft 10 A rigid connection is formed by the horizontal axis 10-2 and the vertical axis 10-1. Both the horizontal axis 10-2 and the vertical axis 10-1 are stepped shafts, and the horizontal axis 10-2 and the vertical axis 10-1 are processed for bearing positioning Shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com