A shale gas pipeline system

A technology for transporting pipelines and shale gas, which is applied in pipeline systems, pipeline supports, pipes/pipe joints/fittings, etc., and can solve the problems of difficulty in quickly judging the leakage location, waste of shale gas leakage, and poor shock absorption effect. , to achieve the effect of simple structure, preventing leakage and improving shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

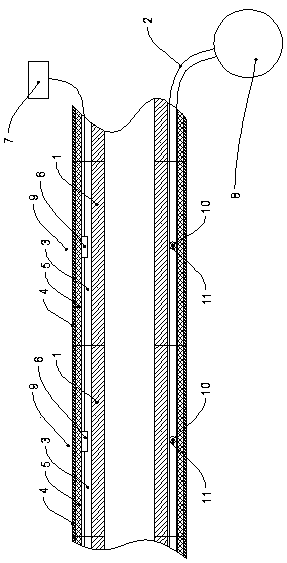

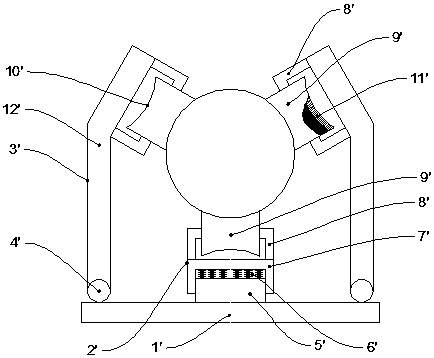

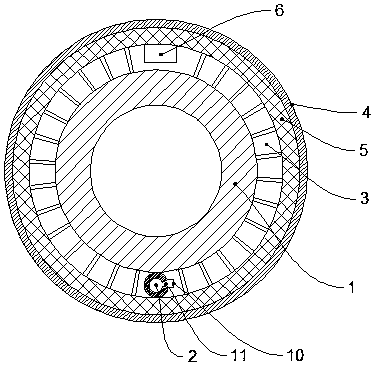

[0040] The optimal implementation mode: if Figure 1-3 As shown, a shale gas transmission pipeline system includes a shale gas pipeline anti-leakage section. A leak detection structure is also provided.

[0041] Among them, at least two fitting supports 9' arranged around the circumference of the shale gas pipeline are installed on the mounting bracket, and one side of the fitting supports 9' is used to fit the surface of the shale gas pipeline to realize the alignment of the shale gas pipeline. The support is fixed and the side surface is provided with an elastic shock-absorbing layer 11'.

[0042] In this way, it is possible to rely on the elastic shock-absorbing layer that fits the support to realize the fit and support of the shale gas pipeline, rely on its elasticity to achieve a shock-absorbing effect, and prolong the service life of the pipeline.

[0043] Wherein, there are three fitting supports 9' and they are evenly arranged around the circumference of the shale ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com