Material layer thickening device for sintering

A material and sintering machine technology, applied in the field of sintering material layer thickening device, can solve the problems of increasing the thickness of the material layer, increasing the height of the sintering machine, increasing the capital investment of the sintering system, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

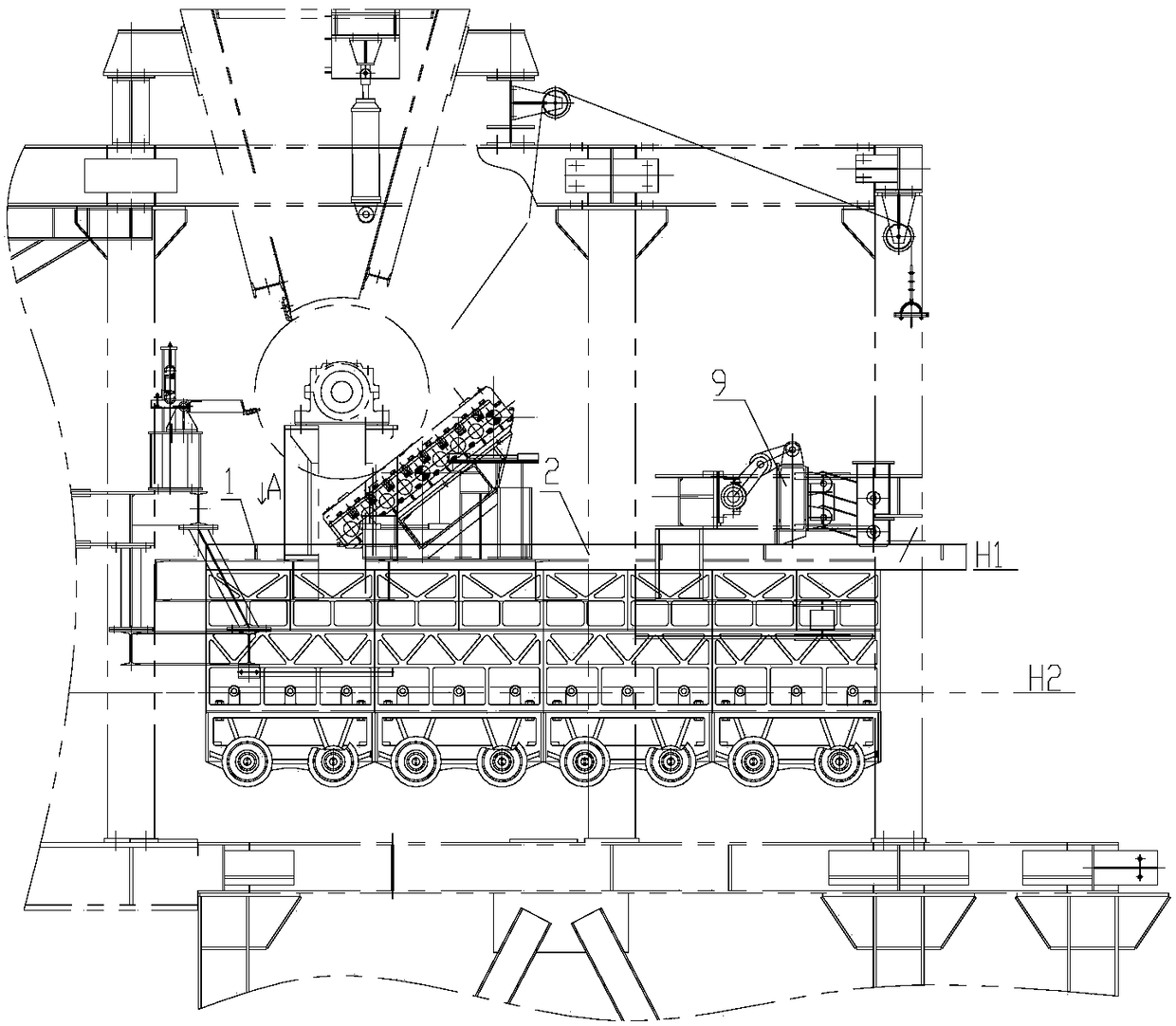

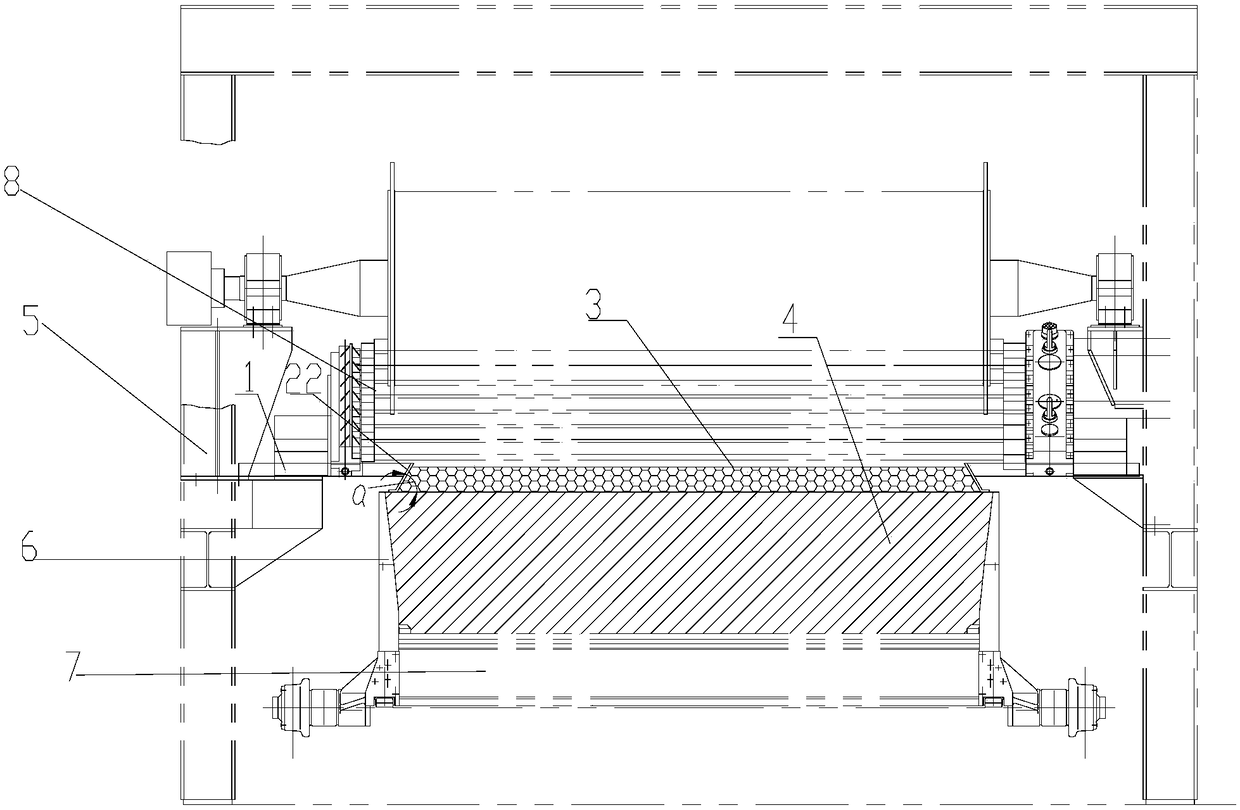

[0021] Among the figure, label H1 represents the horizontal height plane of the former trolley material layer 4, and H2 represents the height plane of the trolley grate bar.

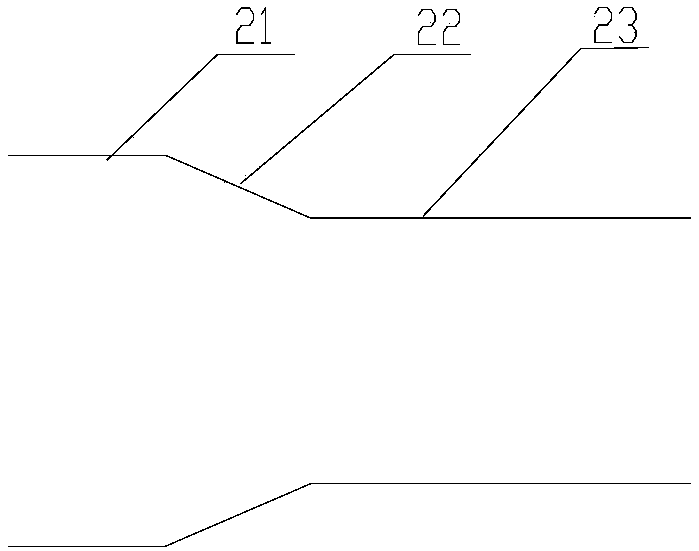

[0022] The device for thickening the material layer for sintering in this embodiment includes a guard plate 2 that fixes the frame 5 of the sintering machine through a bracket 1, and the guard plate includes two sub-guard plates that are oppositely arranged above the side panels 6 on both sides of the trolley 7 of the sintering machine , the guard plate includes a blanking section guard plate 21 and a stacking section guard plate 22 connected to each other, wherein the blanking section guard plate is vertically arranged on both sides of the distributor 8 along the running direction of the sintering machine, and the stacking section guard plate The front end of the plate 22 is connected to the end of the unloading section guard plate 21 and is aligned and connected between the connected guard plates. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com