Intelligent and automatic storage check robot and working method thereof

A robot and intelligent technology, applied in the direction of instruments, computer parts, electromagnetic radiation induction, etc., can solve the problems of narrow warehouse passages and high energy consumption, and achieve the effect of avoiding missed readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

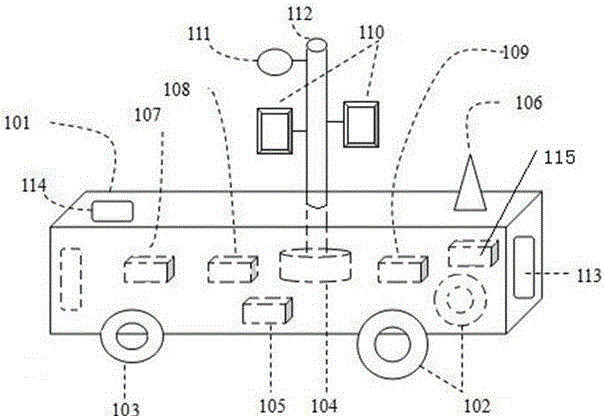

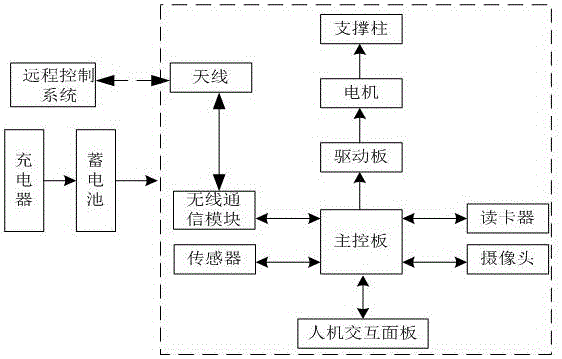

[0014] A storage intelligent automatic inventory robot, including a housing, also includes a front universal wheel arranged at the front end of the lower part of the housing, and a rear universal wheel at the rear end of the lower part of the housing; the control end of the rear universal wheel is connected to the The internal drive board is connected; the upper part of the housing is provided with a supporting column; the supporting column is connected to the output of the rotating motor inside the housing; the control end of the rotating motor is connected to the driving board; the supporting column is An RFID card reader and a camera are provided; a sensor is also provided on the surface of the housing; the drive board, the RFID card reader, the camera and the sensor are respectively connected to the main control board arranged inside the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com