A cleaning device for damaged fuel assemblies

A fuel assembly and cleaning device technology, which is applied in nuclear engineering, radioactive purification, etc., can solve problems such as not seen, and achieve the effects of improving utilization rate, good cleaning effect, and avoiding diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

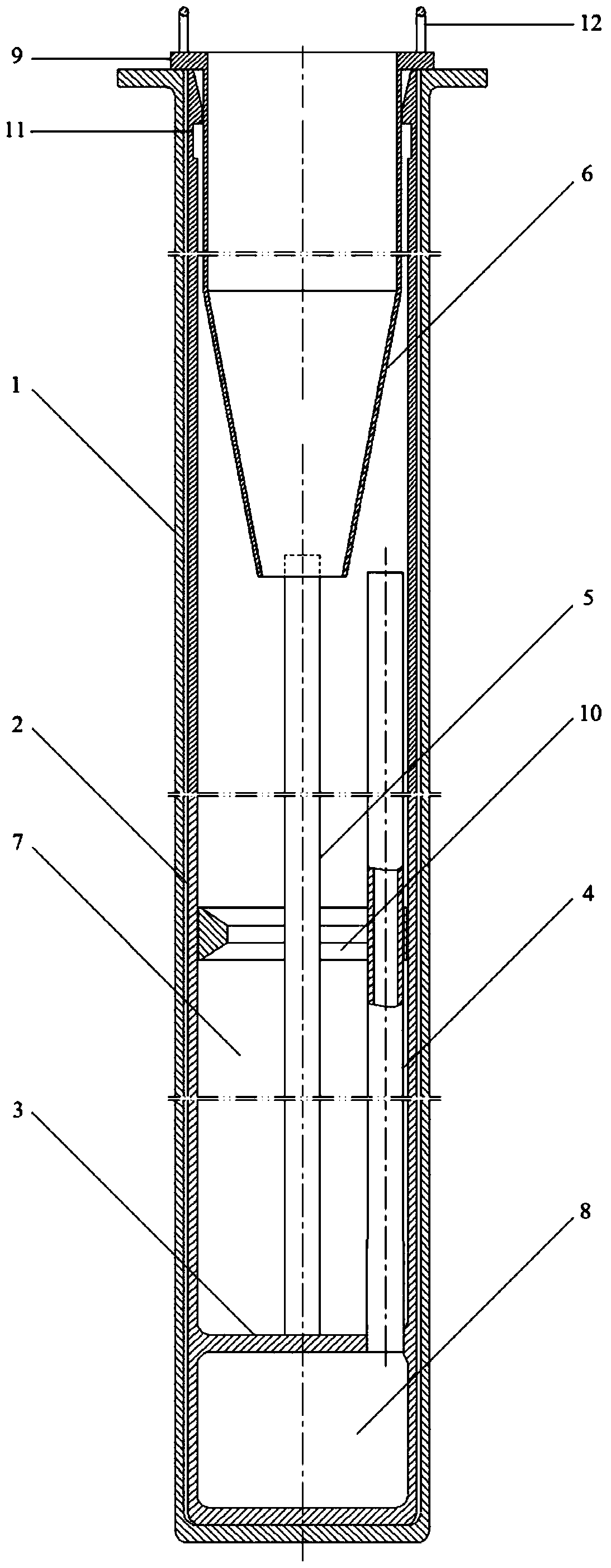

[0023] as attached figure 1 As shown, the cleaning device for damaged fuel assemblies of the present invention includes an outer cylinder 1, an inner cylinder 2, a partition 3, an overflow pipe 4, a breathing pipe 5 and a suspension tube 6; the outer cylinder 1 and the inner cylinder 2 are bottomed A closed-end cylinder; the inner cylinder 2 is placed inside the outer cylinder 1, and the inner cylinder 2 is divided into two parts by the partition 3, the upper part is the cleaning chamber 7, and the lower part is the overflow chamber 8; the overflow pipe 4 is located in the cleaning chamber 7, the upper end of the overflow pipe 4 is open, and the lower end is connected with the overflow chamber 8; the breathing pipe 5 is located in the cleaning chamber 7, the upper end of the breathing pipe 5 is open, and the opening end is higher than the upper end of the overflow pipe 4 Opening, the lower end communicates with the overflow chamber 8; the hanging tube 6 is located in the upper...

Embodiment 2

[0026] The damaged fuel assembly of a certain sodium-cooled fast neutron reactor is cleaned by the cleaning device for the damaged fuel assembly of Example 1, and the basic process is as follows:

[0027] (1) Add an appropriate amount of metallic lead to the inner cylinder 2, and heat to melt the lead;

[0028] (2) Hang the damaged fuel assembly from the center of the hanging tube 6 into the cleaning chamber 7 of the inner cylinder 2, so that the damaged fuel assembly is immersed in the molten lead; the sodium adhering to the damaged fuel assembly reacts gradually with the lead in the cleaning chamber 7 to form an alloy , the molten surface material flows into the overflow chamber 8 from the overflow pipe 4;

[0029] (3) After the reaction is finished, the damaged fuel assembly is lifted from the inner cylinder 2, the heating is stopped, and the cleaning is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com