Pixel Array, Electro Optical Device, Electric Apparatus And Method Of Driving Pixel Array

A pixel array and pixel technology, applied in the field of pixel array, can solve the problems of decreased light utilization rate and increased power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

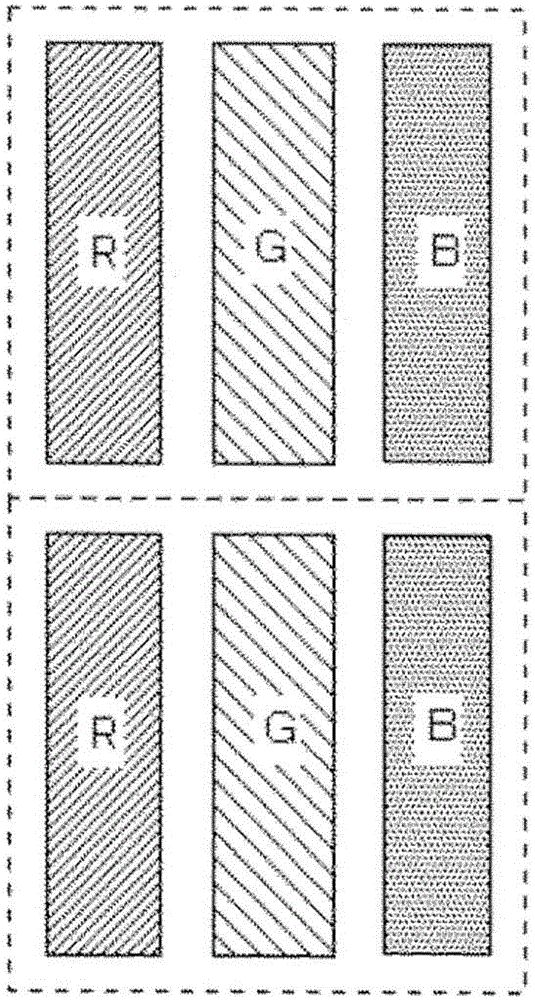

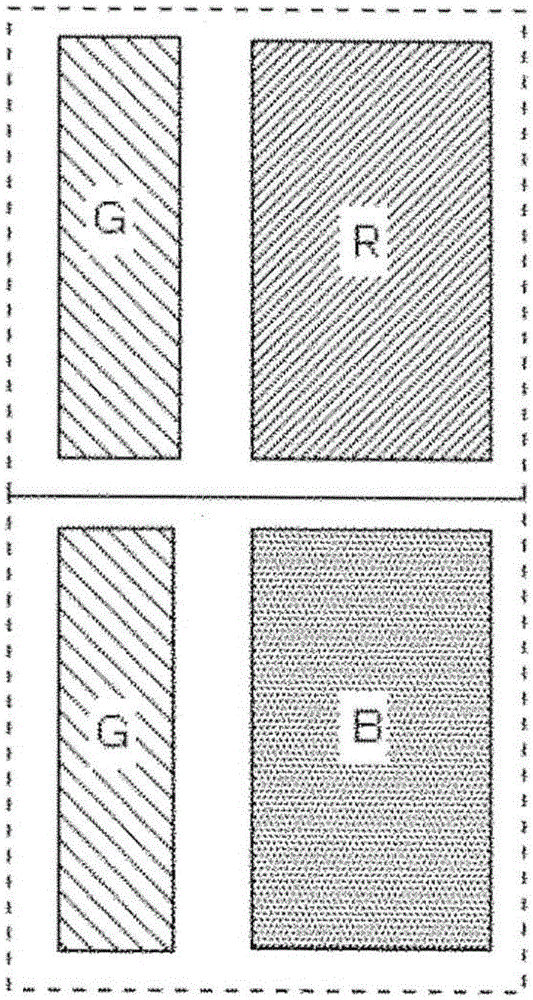

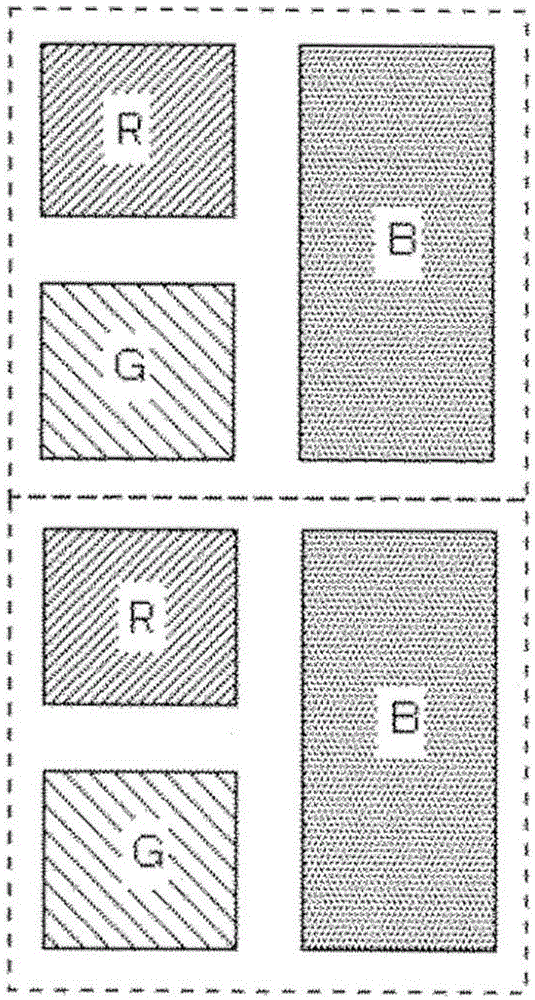

[0095] Next, refer to Figure 22 to Figure 29 The pixel array and electro-optical device according to the first embodiment will be described.

[0096] In the above-mentioned embodiments, the pixel arrangement structure of the electro-optic device (organic EL display device) was particularly described, but this embodiment is concerned with the manufacture of an organic EL display device including a pixel array having the above-mentioned pixel arrangement structure. The method is explained. Figure 22 , Figure 24 , Figure 26 and Figure 28 is has Figure 10 A top view of a pixel of the pixel arrangement shown, while Figure 23 , Figure 25 , Figure 27 and Figure 29 With Figure 22 , Figure 24 , Figure 26 and Figure 28 Correspondingly, for the sake of illustration, a cross-sectional view of a TFT portion, a storage capacitor portion, and a light emitting element shown in one sub-pixel is particularly extracted.

[0097] First, if Figure 22 and Figure 23As ...

no. 2 example

[0108] Next, refer to Figure 30 to Figure 33 An electro-optical device and an electric device according to the second embodiment will be described. In the second embodiment, as an application example of the organic EL display device, various electric equipment including the organic EL display device as a display unit will be described.

[0109] Figure 30 to Figure 33 An example of an electrical device to which an electro-optical device (organic EL display device) is applied is shown. Figure 30 is an example applied to a personal computer, Figure 31 It is an example of application to portable terminal devices such as personal digital assistants (PDAs), electronic notepads, e-books, or tablet terminals. Figure 32 is an example applied to smartphones, and Figure 33 is an example applied to mobile phones. The organic EL display device 400 can be used for display portions of these types of electrical equipment. Applicable to any electrical equipment provided with a disp...

no. 3 example

[0111] Next, refer to Figure 34 to Figure 37 An electro-optical device and electrical equipment according to a third embodiment will be described. In the above-mentioned second embodiment, the case where the organic EL display device as an electro-optical device is applied to an electric device provided with a planar display portion has been described. However, by making the organic EL display device deformable, the organic EL display The device can also be applied to electrical equipment that requires a curved display.

[0112] Figure 34 It is a cross-sectional view showing the structure of a deformable organic EL display device. This structure is different from the above-mentioned first embodiment in that: (1) TFT portion 108 (M1 switch TFT 108a, M2 drive TFT 108b) and storage capacitor portion 109 are formed on a flexible substrate; (2) no sealing glass is arranged on light emitting element 116 Substrate 200.

[0113] First, regarding (1), a peeling film 120 of organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com