Array flexible curved surface self-sensing driver based on IPMC and preparation method thereof

A self-sensing and driver technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc. Design and exploration, distribution design of array-type flexible actuators and research gaps, etc., to achieve the effect of simple structure and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

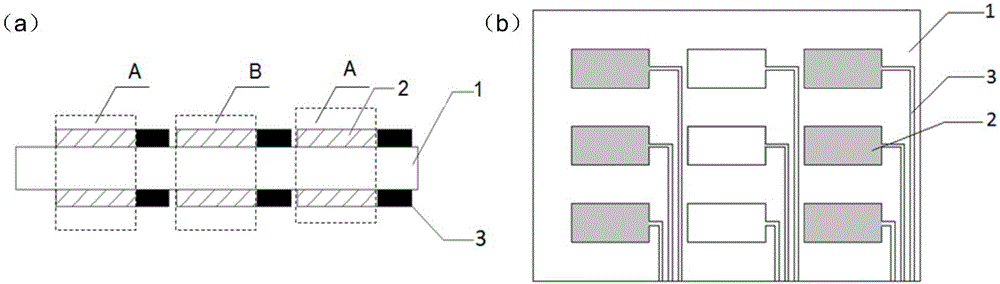

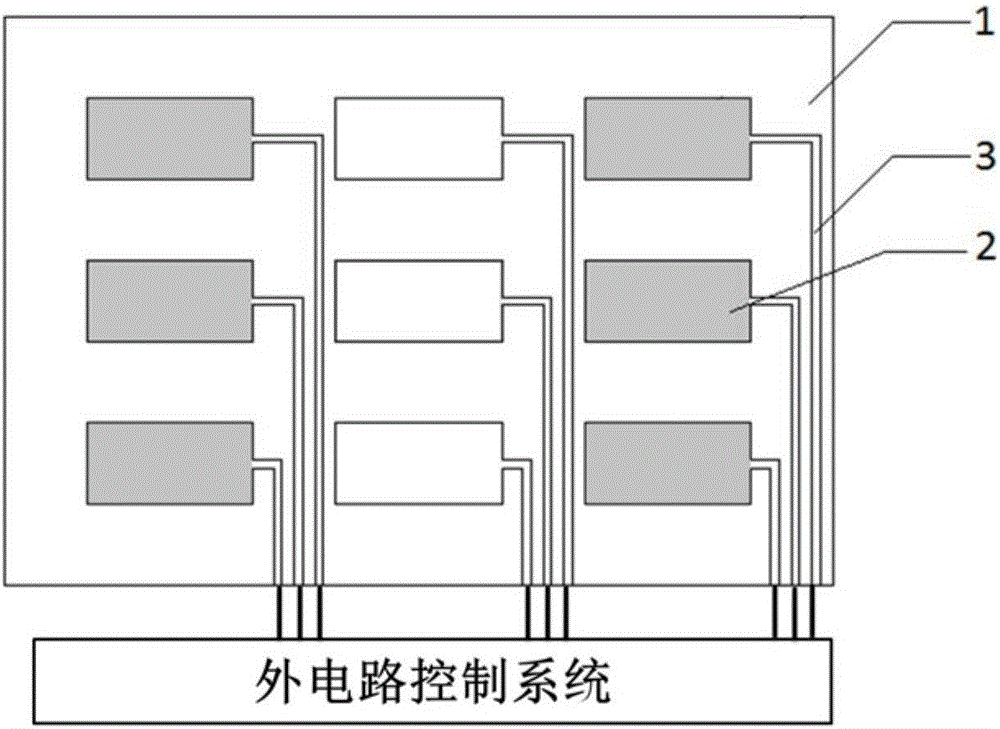

[0029] Such as figure 1 As shown, the present embodiment is based on the array type flexible curved surface self-sensing driver of IPMC. A plurality of sheet electrodes 2 are arranged in a 3×3 square array on the upper and lower surfaces of the polyelectrolyte flexible substrate layer 1, and are located on the upper surface. The plurality of sheet electrodes on the surface are symmetrical to the plurality of sheet electrodes on the lower surface;

[0030] Two symmetrical sheet electrodes and a part of polyelectrolyte flexible matrix layer clamped between the two sheet electrodes form a functional element, the functional element is a sensing functional element A or an actuating functional element B; on the self-sensing driver at the same time a presence sensing function and an actuation function;

[0031] There are circuits 3 extending outwards from the edge of each sheet electrode, and each circuit is drawn from one side of the polyelectrolyte flexible matrix layer and connec...

Embodiment 2

[0047] The structure and size of the array type flexible curved surface self-sensing driver based on IPMC in this embodiment are the same as those in Embodiment 1, and are specifically prepared according to the following steps:

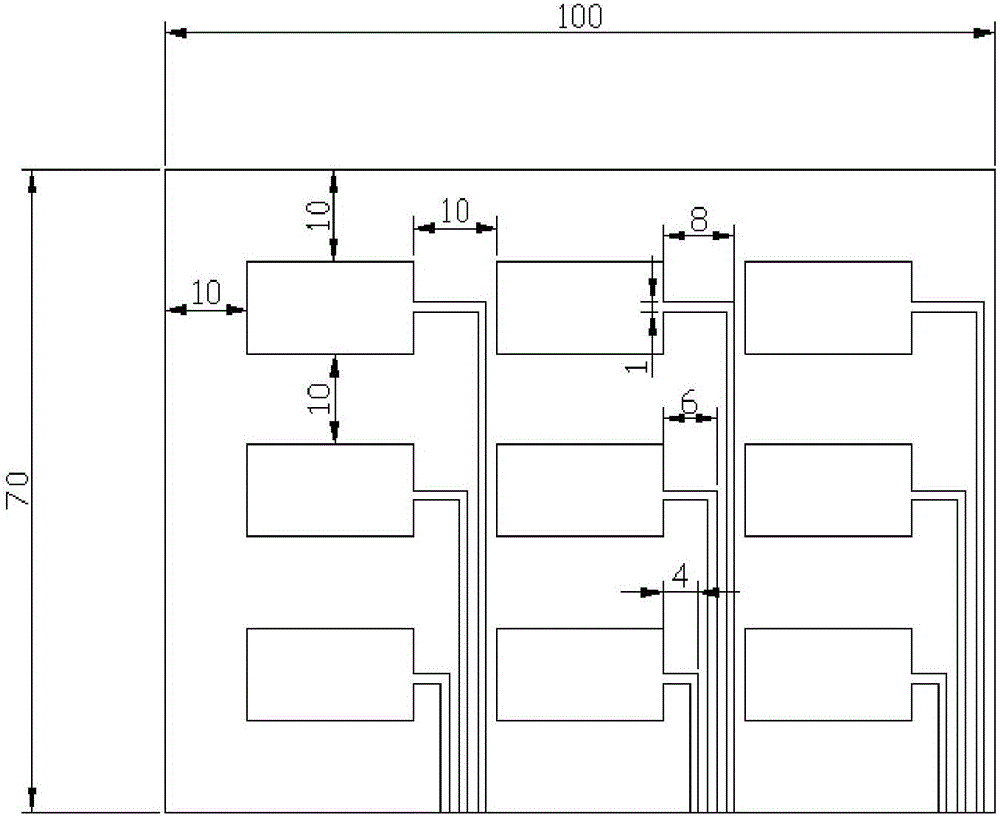

[0048] (1) The Nafion-117 ion membrane produced by DuPont Company of the United States was used as the flexible substrate layer, and it was cut to a rectangle of 100mm×70mm.

[0049] (2) as figure 2 In the form shown, the transparent glue is used as a mask material to cover the part on the surface of the polyelectrolyte flexible matrix layer that does not need to be plated with sheet electrodes and circuits for positioning.

[0050] (3) Cut the gold foil into the shape of a sheet electrode extending with a circuit, and cover it on one side of the flexible substrate layer, and then flatten it and perform hot pressing on a tablet press. The tablet pressing temperature is 60 ° C, pressure 0.6MPa, and the duration is 4min, so as to form an electrode lay...

Embodiment 3

[0054] The structure and size of the array type flexible curved surface self-sensing driver based on IPMC in this embodiment are the same as those in Embodiment 1, and are specifically prepared according to the following steps:

[0055] (1) The Nafion-117 ion membrane produced by DuPont Company of the United States was used as the polyelectrolyte flexible matrix layer, and it was cut into a rectangle of 100mm×70mm.

[0056] (2) Mix the liquid Nafion-117 ionic membrane and the flocculent carbon nanotube material at a mass ratio of 1:2, and stir evenly with magnetic force to make a mixed solution;

[0057] Cast the mixed solution in a mold with a specification of 10cm (thickness)×7cm×10cm, and heat the mold evenly at a heating temperature of 80°C. After the mixed solution evaporates and forms a film, stop heating to obtain the electrode layer film of the required specification .

[0058] (3) Both surfaces of the Nafion-117 ionic membrane are pasted with an electrode layer film,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com