A terminal fixing device assembly

A technology of fixing device and fastening device, applied in the direction of cable suspension device, electrical components, overhead installation, etc., can solve the problems of damp waterproof structure, endangering the safety of power facilities, troublesome disassembly, etc. Moisture resistance, increase waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

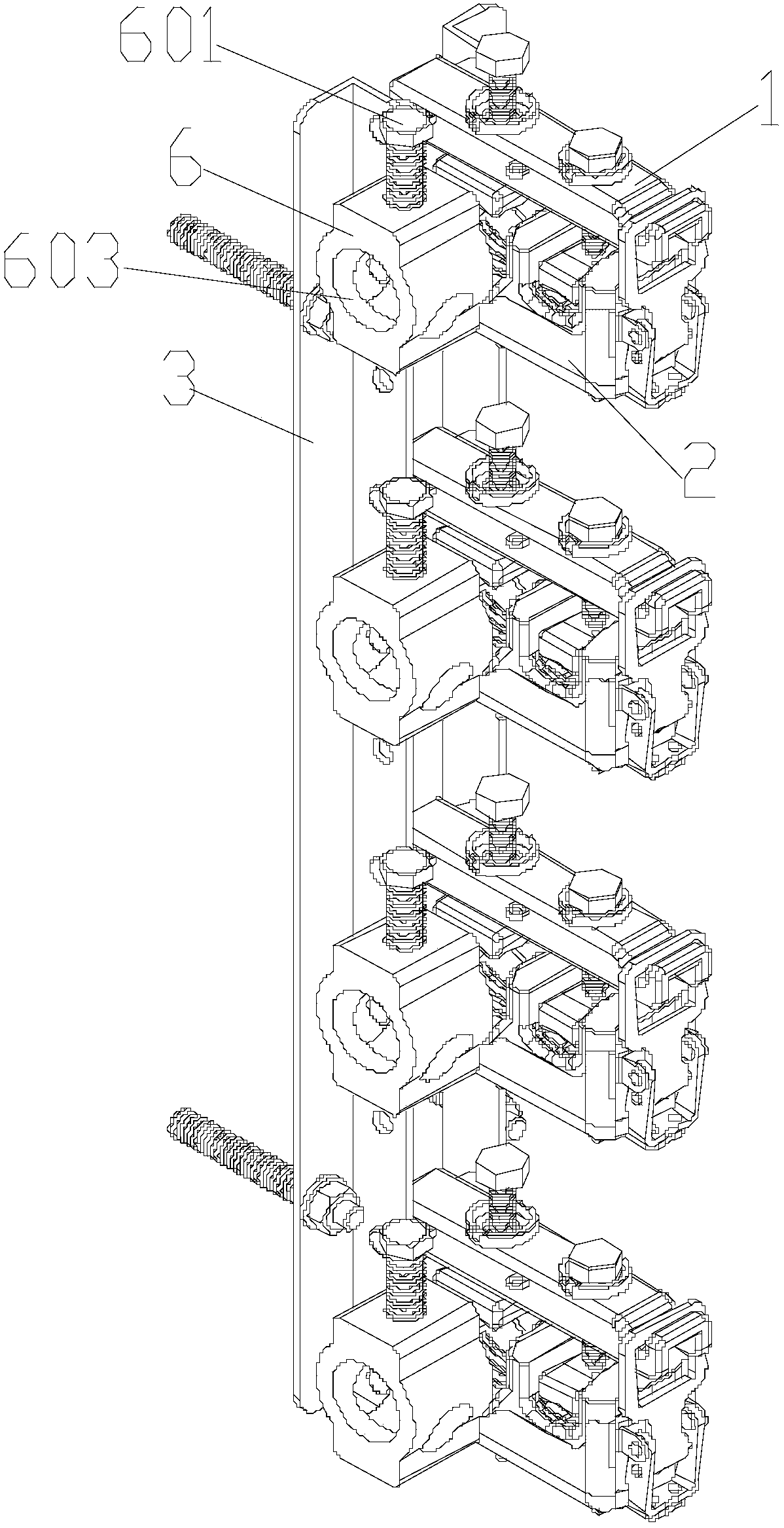

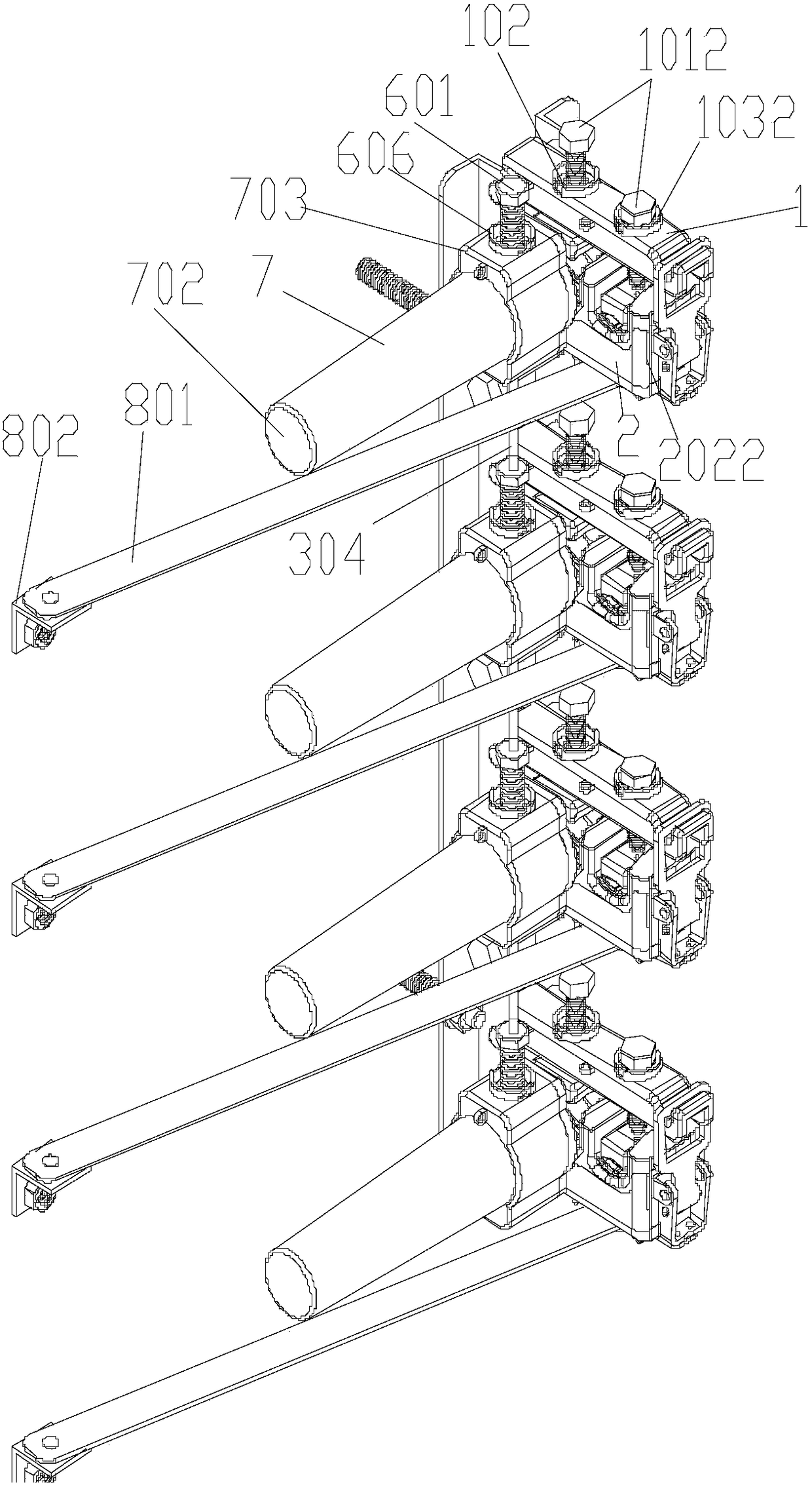

[0058] Such as Figure 1-13 As shown, a terminal fixing device assembly includes a fixing device, and also includes a cable terminal fastening device arranged on the side of the fixing device close to the cable terminal. The cable terminal fastening device includes a fastening block 6 and a fastening block. Fastening bolt 601, the fastening block 6 is provided with fastening threaded hole 602 that cooperates with fastening bolt 601 and a wire hole 603 for cable terminal to pass through, and one end of fastening bolt 601 passes through fastening threaded hole 602 and inserts the cable The insulating sheath of the terminal is clamped with the insulating sheath so as to fix the cable terminal and the fastening block 6 .

[0059] Such as Figure 3-13 As shown, the cable terminal fastening device also includes a protective tube 7. The protective tube 7 is a tubular body structure with an open end 701 and a closed end 702. The open end 701 is connected to the wire hole 603. The inn...

Embodiment 2

[0094] On the basis of the technical solution of the terminal line fixing device assembly in embodiment 1, further improvements are made as follows:

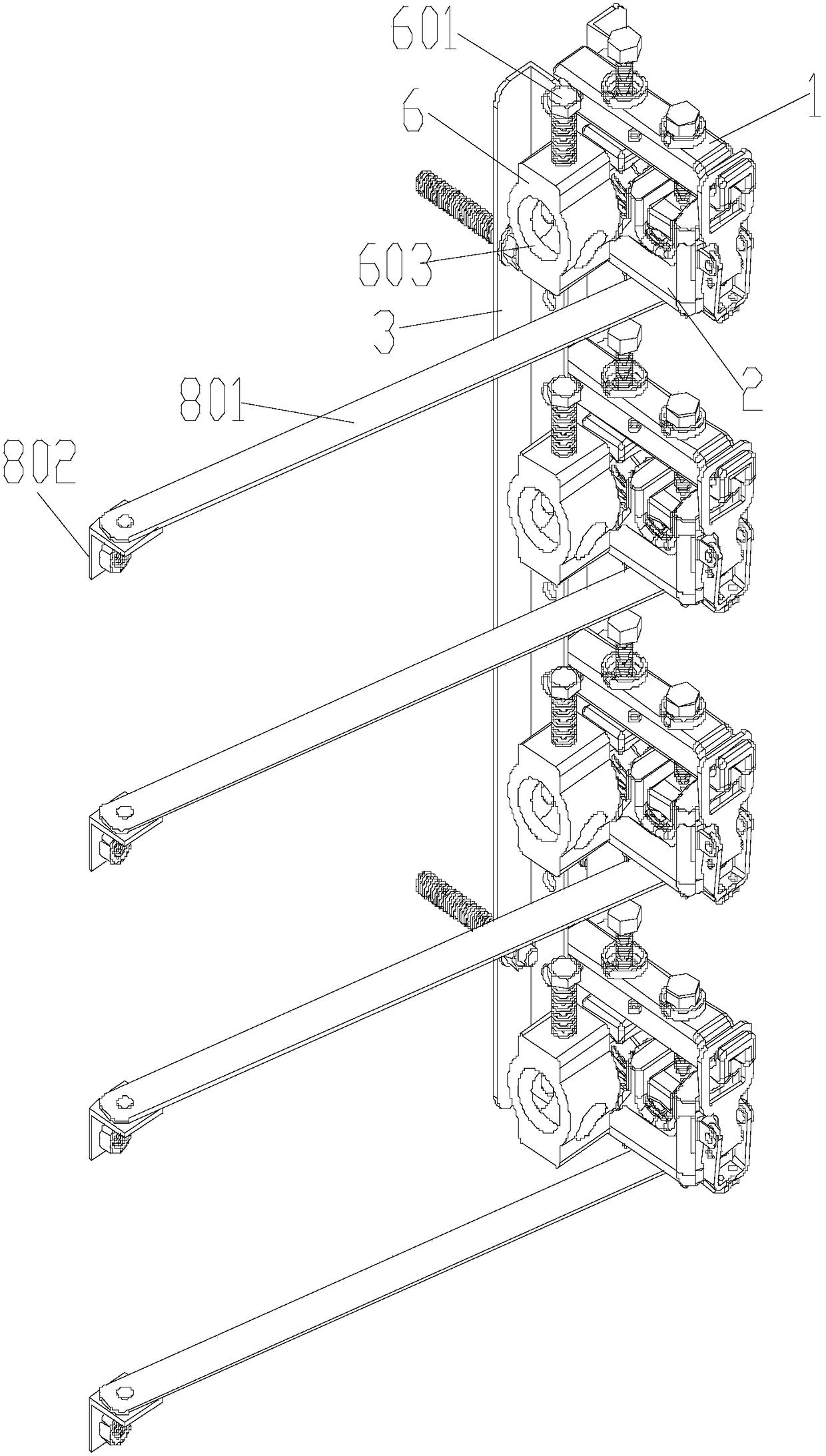

[0095] Such as Figure 2-4 As shown, the wire passing device is connected with a reinforcing device that can be fixed to the wall. The structure of the reinforcing device is a supporting straight plate 801 and a rotating folded plate 802. One end of the supporting straight plate 801 and a folded plate of the rotating folded plate 802 It can be connected rotatably, and the other end is connected with the wire passing device through bolts. The other folded plate of the rotating folded plate 802 is provided with a through hole through which the bolt is fixedly connected with the wall.

[0096] The support straight plate is arranged on the same side of the cable terminal fastening device.

Embodiment 3

[0098] On the basis of the technical solution of the terminal line fixing device assembly in embodiment 1, further improvements are made as follows:

[0099] Such as Figure 3-13 As shown, the cable terminal fastening device is also provided with a first protective cover 605 for protecting the fastening bolts 601 .

[0100] The cable terminal fastening device is also provided with a first buckle device that cooperates with the first protective cover 605 .

[0101] The first buckle device is a first rotating buckle 606 arranged on the flange surrounding the fastening threaded hole 602. During use, rotating the first protective cover 605 can lock it with the first rotating buckle 606 or Open.

[0102] The first protective cover 605 is connected to the cable terminal fastening device through a first connecting wire 607, one end of the first connecting wire 607 is fixed on the first protective cover 605, and the other end is fixed on the cable terminal fastening device.

[0103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com