Accuracy inspection and calibration device and inspection and calibration method of non-contact tonometer

A non-contact, calibration device technology, applied in the direction of tonometer, medical science, surgery, etc., can solve the problem of not considering the density of human eye aqueous medium, incompressibility, not considering the actual cavity volume, measurement accuracy Low-level problems, to achieve the effect of door-to-door verification service, ingenious design, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

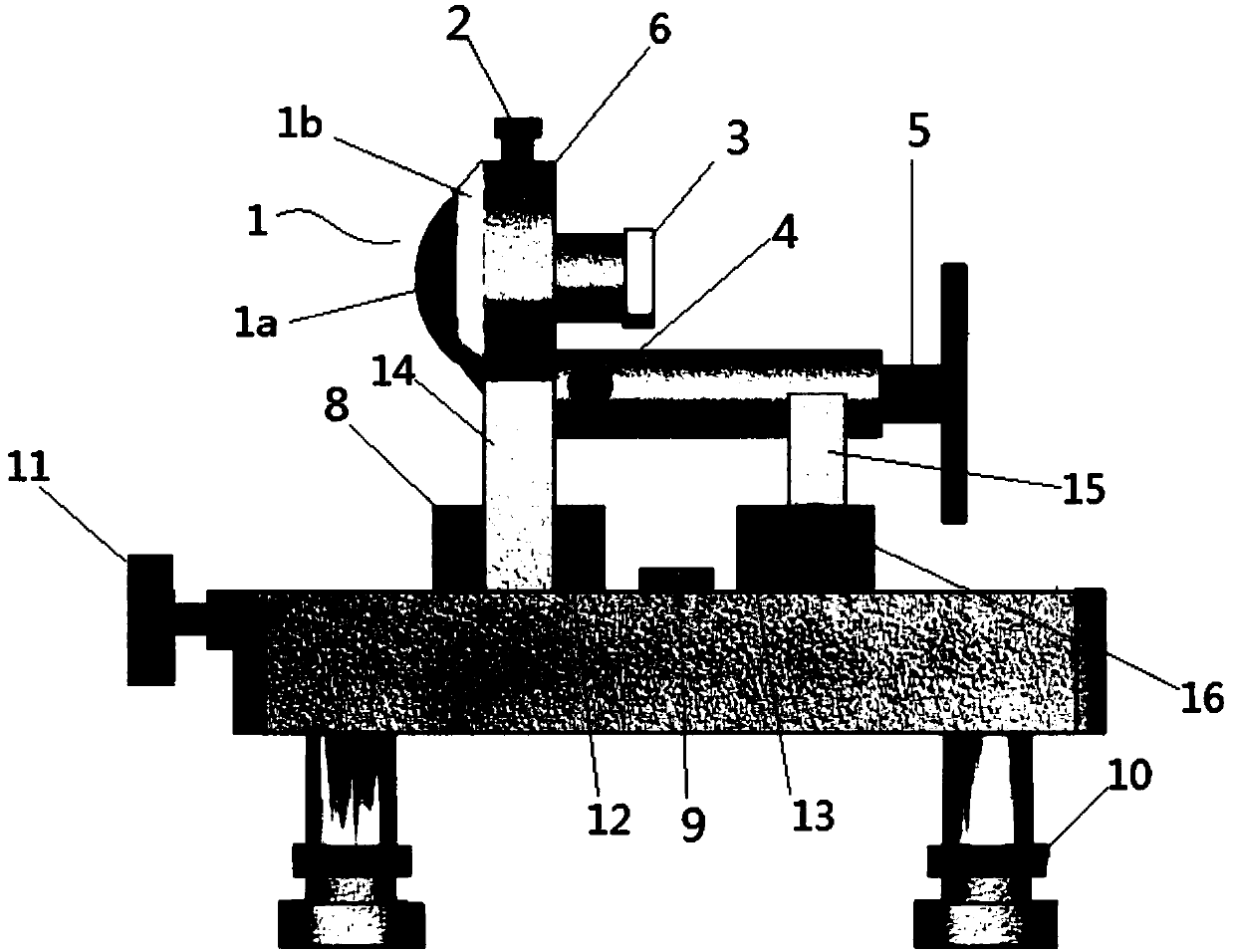

[0042] The device developed by the invention uses self-made bionics to simulate the human eye, the volume of the intraocular pressure cavity is close to the real situation, the mechanical properties of the pressure transmission fluid are basically consistent with the aqueous humor, and the verification of the non-contact applanation tonometer is realized. At the same time, by installing the positioning adjustment module, the installation of the precision inspection and calibration module is realized, and the positioning and carrying are also very convenient, which is conducive to the realization of door-to-door service for medical structures.

[0043] The specific plan is as follows:

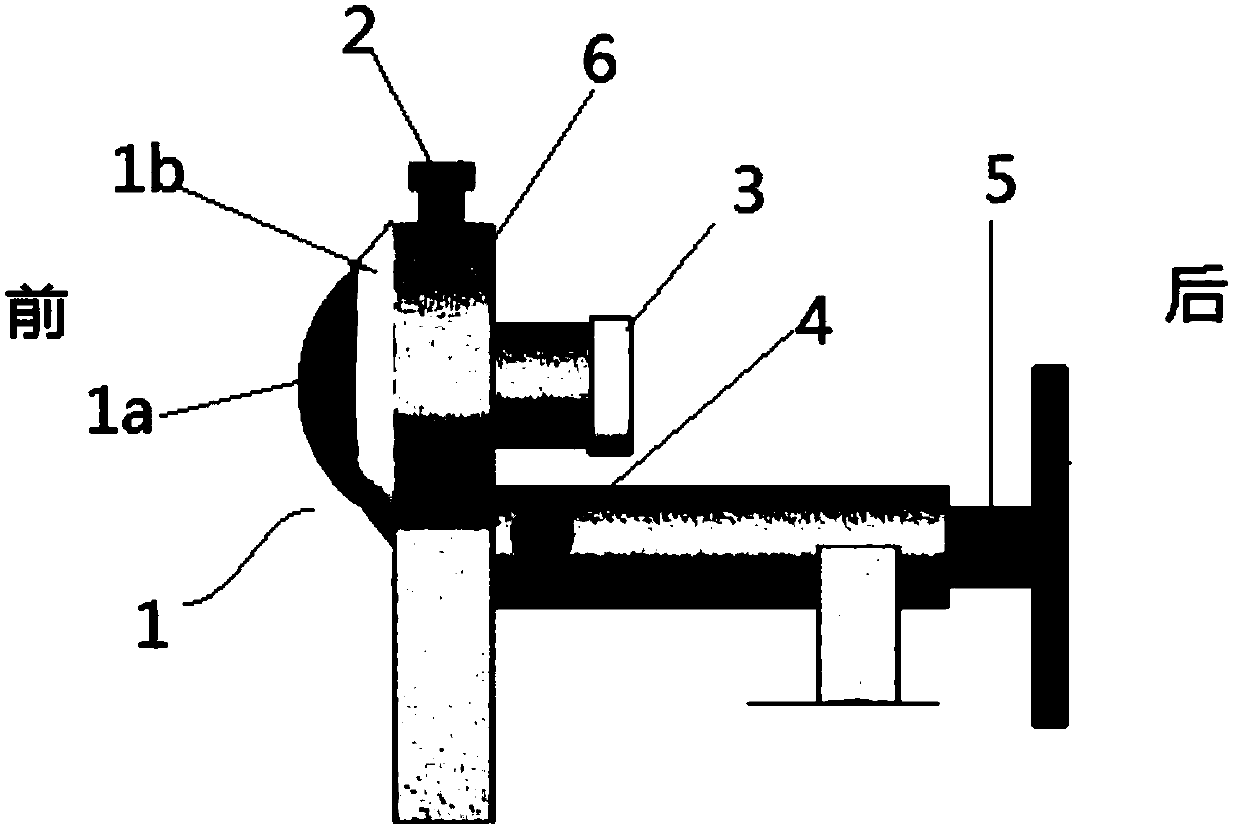

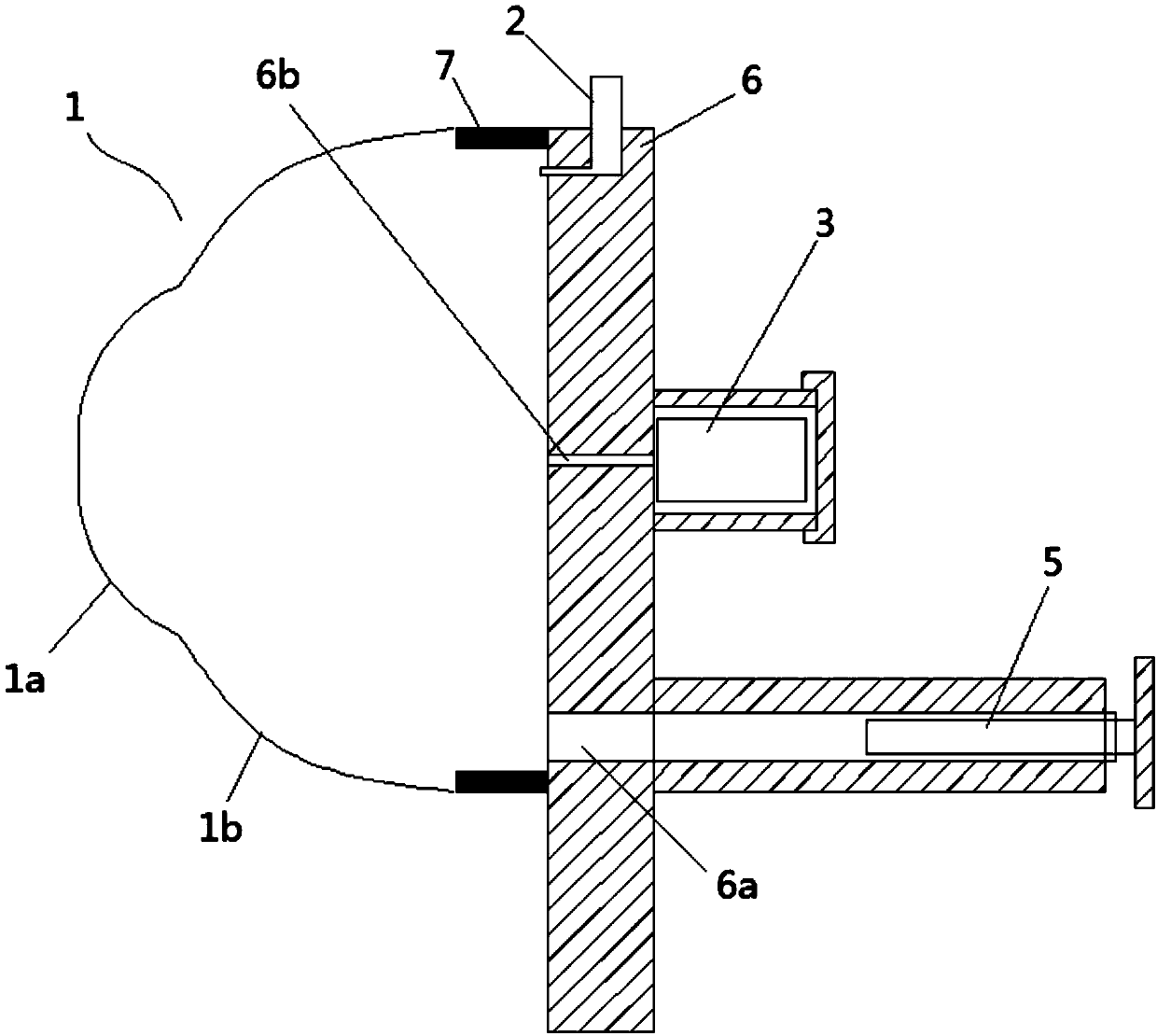

[0044] see Figure 1-Figure 3 , a non-contact tonometer accuracy inspection and calibration device, including an accuracy inspection and calibration module, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com