A gas demister for acetylene hydrogenation to ethylene slurry bed

A technology of acetylene hydrogenation and demister, which is applied in the direction of hydrogenation hydrocarbon production, chemical instruments and methods, separation methods, etc., can solve the problems of single function and complex structure, and achieve high defoaming efficiency, small volume and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

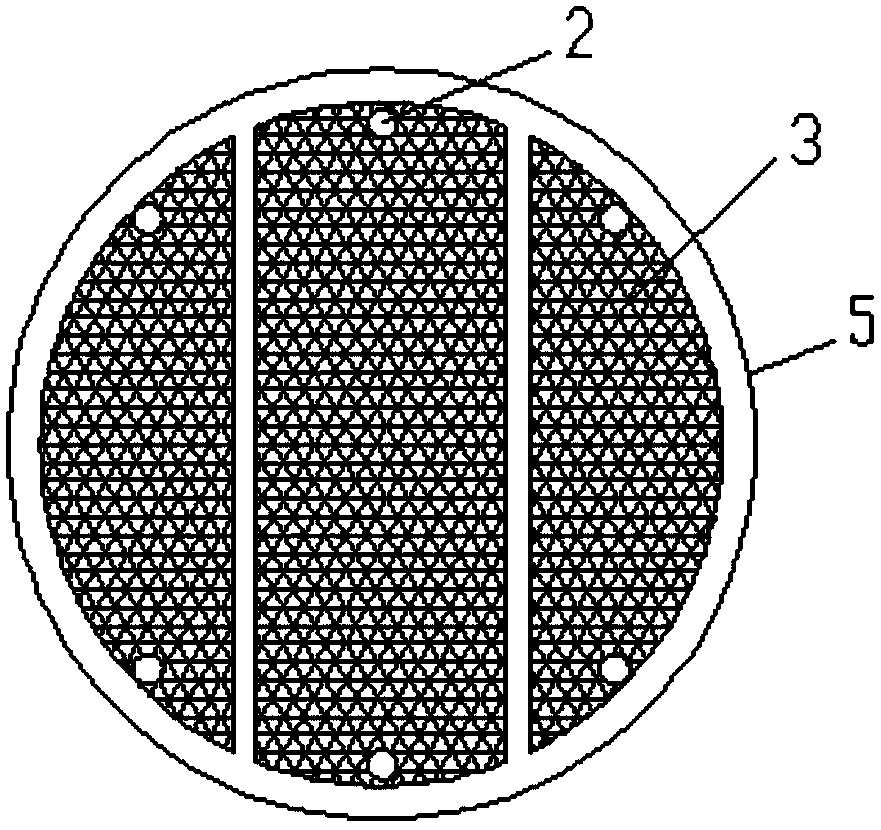

[0030] This embodiment relates to a gas demister according to the present invention, its structure is as follows figure 2 :

[0031] The demister is a hard wire mesh with a mesh number of 20, and a catalyst layer with a thickness of 0.5 μm-20 μm is provided on the surface of the hard wire mesh;

[0032] The catalyst active ingredient in the catalyst layer is metal palladium particles;

[0033] The particle size of the active ingredient of the catalyst is 50-100nm;

[0034] The weight percent of the catalyst active ingredient in the catalyst layer is 0.05%

[0035] The carrier of the active component of the catalyst in the catalyst layer is α-Al 2 o 3 ;

[0036] The material of the hard screen is polytetrafluoroethylene;

[0037] The hard screen is composed of three screen modules.

Embodiment 2

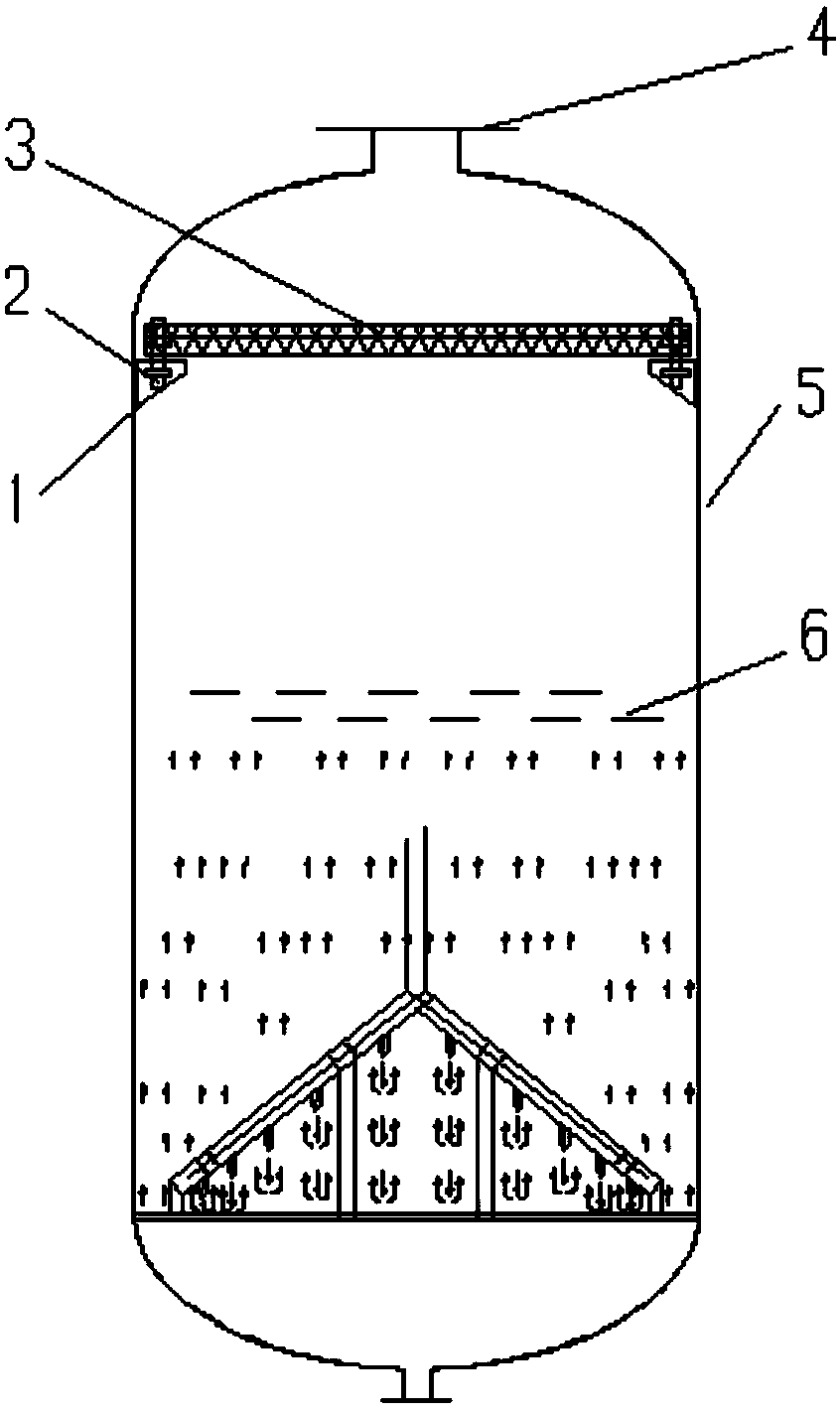

[0039] This embodiment relates to the ethylene slurry bed comprising the gas demister of the present invention, such as figure 1 As shown, it includes a wire mesh support block 1 installed on the inner wall 5 of the reactor, and the wire mesh module 3 fixes the wire mesh on the wire mesh support block 1 through wire mesh fixing bolts 2 . The mesh number of the screen block is 15 meshes; the number of the screen modules is 3; the screen support block 1 is movably connected with the screen module 3 . The wire mesh module 3 is made of high-strength polytetrafluoroethylene.

[0040] When the gas with mist enters the upper part of the reactor from the solvent level 6 of the reactor, and rises through the screen module 3 at a certain speed, due to the inertia of the mist rising, the mist collides with the screen block and is attached on the screen surface. The diffusion of the mist on the surface of the fine mesh and the gravity settlement of the mist are the formation of larger d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com