A solution to starting shaking and electrical brake noise of a battery electric vehicle

A technology of pure electric vehicles and solutions, which is applied in the field of pure electric vehicle starting jitter and electric brake noise, can solve problems such as the inability to reduce jitter frequency and sacrifice of vehicle dynamic performance, and achieve suppression of starting jitter, afterburning process and The withdrawal process is smooth and smooth, reducing the effect of mechanical shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

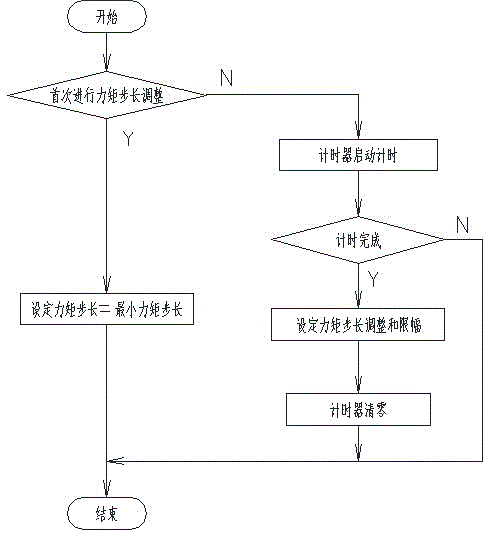

Image

Examples

Embodiment Construction

[0017] The solution of pure electric vehicle starting jitter and electric brake noise of the present invention comprises the following steps:

[0018] Step 1. Define the given accelerator torque as the set value of the motor torque after the analysis of the accelerator pedal opening, the motor feedback torque is the torque value that the motor has actually reached during the execution of torque control, and the step size of the rising torque is the absolute value of the motor feedback torque In the process of increasing the value, the maximum torque value of a single adjustment, the step size of the descending torque is the maximum torque value of a single adjustment in the process of decreasing the absolute value of the motor feedback torque, and the step size of the steady-state torque is in the state of static or motor torque balance Next, the maximum torque value of a single adjustment;

[0019] Step 2, mark the motor torque adjustment state as the ascending torque step ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com