Packer

A technology of packers and tubular parts, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of difficult removal of packers and small radial expansion size of rubber tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

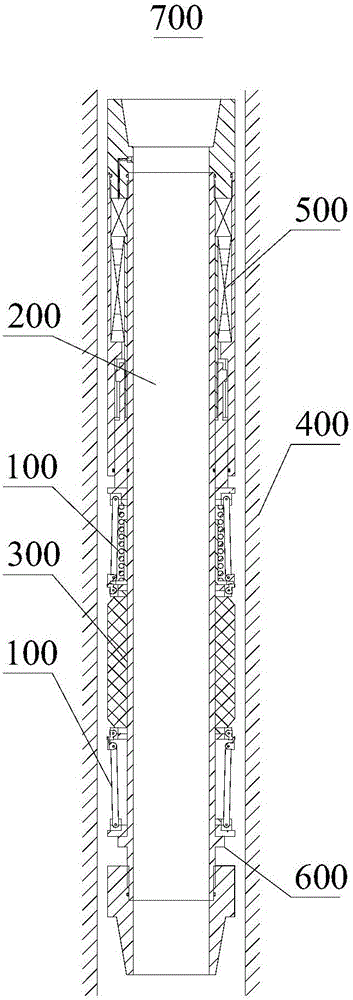

[0063] refer to figure 1 , the two anti-protrusion devices 100 are integrally sleeved on the tubular member 200 . The rubber cylinder 300 is sleeved on the tubular member 200, the rubber cylinder 300 is located between the two anti-protrusion devices 100, the driving device 500 is arranged at the upper end of the tubular member 200, and the limiting device 600 is arranged at the lower end of the tubular member 200, so that the structure is formed. A packer 700. The packer 700 is lowered into the wellbore 400 to separate and seal the wellbore 400 during setting.

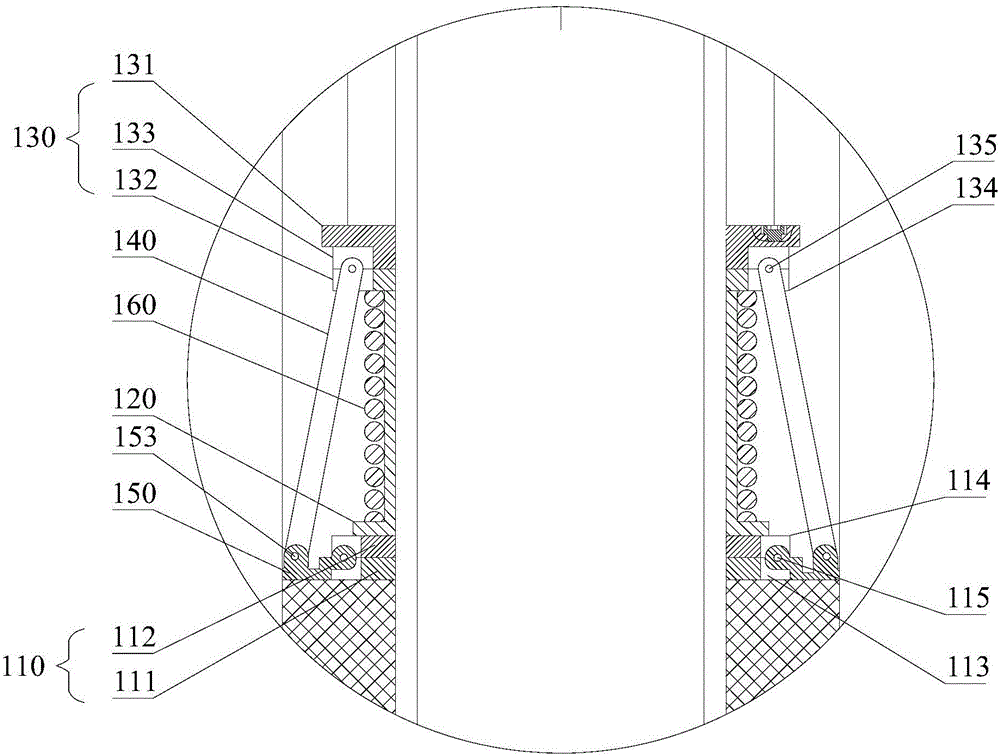

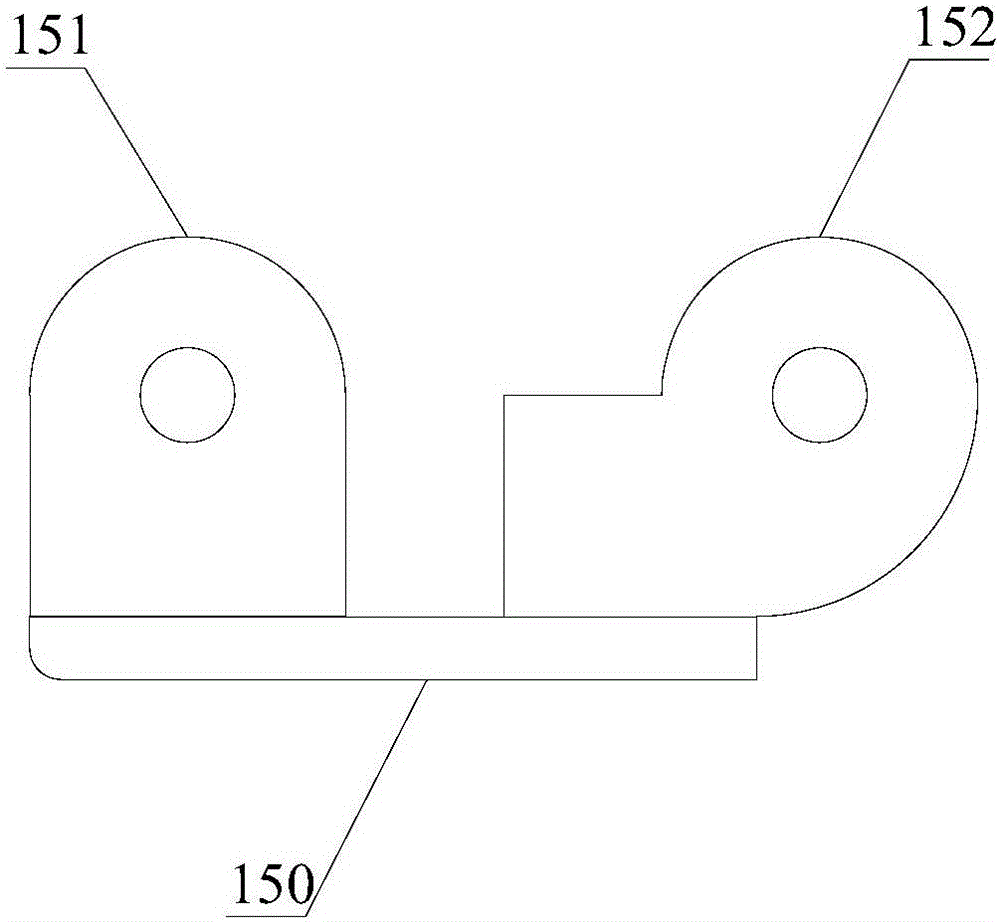

[0064] refer to figure 2 , the anti-slip device 100 includes a body and a wing plate 150 . The body includes an extrusion ring 110 , a limiting member 120 , a pressure bearing ring 130 and a connecting rod 140 .

[0065] The pressure-bearing ring 130 includes an annular pressure-bearing cover 131 and a pressure-bearing seat 132 . The pressure-bearing cover 131 and the pressure-bearing seat 132 are coaxially arran...

Embodiment 2

[0089] Compared with the first embodiment, the present embodiment is different in the driving device 500 and the limiting device 600, and the remaining parts are basically the same as those of the first embodiment.

[0090] refer to Figure 12 , the driving device 500 includes an outer sleeve 510 and a pressure sliding sleeve 540 . The inner surface of the upper joint 530 is fixed on the upper end of the tubular member 200 by screwing. The outer sleeve 510 is sleeved on the tubular member 200, and the outer sleeve 510 is threadedly connected with the outer surface of the upper joint 530 to realize fixing. An annular space with a closed lower end is formed between the inner surface of the outer sleeve 510 and the outer surface of the tubular member 200 . The pressure sliding sleeve 540 is slidably sleeved on the tubular member 200, and seals the open end of the annular space through the sealing rings arranged on the inner peripheral surface and the outer peripheral surface th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com